Wix Filters informs PMM about the importance of cabin air filters, the requirements of air filter gaskets and the effect biocomponents have on fuel filters.

The quality of the air filter gasket affects the entire process of filtration and the air that is sucked in by the engine. Each gasket must provide an airtight and durable connection between the filter and the housing in which the filter is installed.

The basic requirement that the air filter gasket must meet is the appropriate deformation resistance. In the case of Wix filters, it is verified in its laboratory whether the air filter gaskets are adequately deformed even under extreme conditions of operation of the filter by measuring the elasticity of the gasket after a period of 96 hours of compressing it to 60 per cent at 110°C. Also, by measuring the elasticity of the gasket after 500 hours of storing the filter in a climate chamber with the air circulation set at 110°C.

Another important requirement that the air filter gasket must meet is tensile strength and resistance to hydrolysis which are controlled in its laboratory using specialised measuring instruments. This is to ensure Wix air filter gaskets have reliable air tightness of the filter in the installed housing. A lack of tightness can result in damage to pistons, bushes, cylinders, and the turbocharger caused by impure oil getting into the engine.

Fuel filters and biocomponents

Fuels with biocomponents are available at stations, an example being E10 gasoline, with a maximum of 10 per cent bioethanol. Fuel of this type has a much more aggressive effect on certain materials and can react with them.

Therefore, it is important that automotive parts which come into contact with fuel are biocomponent resistant. E10 gasoline resistant materials are used in Wix fuel filters to ensure their proper filter operation, even at extremely high and low temperatures. An example of the materials selected for their resistance to particularly difficult working conditions for the fuel filter is the rubber compounds of which the filter seals are made. Two types of mixture are used in the company’s filters:

Nitrile Rubber: The raw material of this rubber is adjusted to the specifications determined by the company, based on laboratory tests. It is resistant to temperatures ranging from -30 to +110°C.

Fluorosilicone rubber: This type of rubber has been used for many years in the aerospace industry. FVMQ rubber is used to produce seals for selected Wix filters in order to provide increased gasket resistance to separation and deformation at extreme temperatures. This rubber is resistant to temperatures ranging from -80 to +230°C.

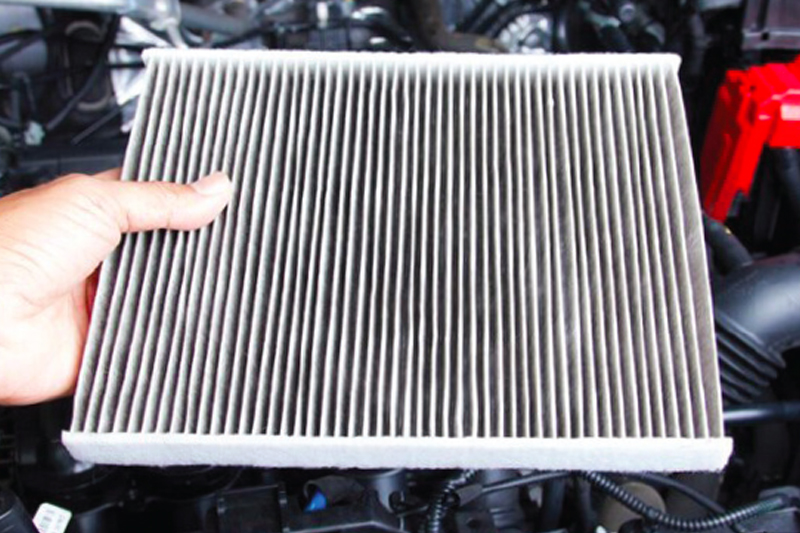

What does a cabin filter protect us from?

A cabin filter purifies the air which the passengers and the driver breathe. The filter should be replaced at least once a year, or every 15,000 km. Five threats you can avoid:

- Breathing in contaminants: The cabin filter retains microparticles of dust and plant pollen. Inhaling polluted air has negative effects on your health.

- Fatigue and reduced travel safety: Polluted air in the passenger compartment causes discomfort and fatigue and can significantly decrease the concentration of the driver.

- Poor visibility: Moisture particles rest on the surface of a worn-out cabin filter; this moisture enters the passenger compartment of the car and causes the windows to fog up, causing poor visibility.

- Reduced efficiency of the air conditioning system: Over time, every cabin filter becomes clogged with contaminants, leading to reduced air conditioning.

- Allergic reactions: Using a vehicle with a contaminated cabin filter can cause irritation in the eyes, sneezing, or nasal congestion.