Stuart Still, Technical Trainer at EEC deals with one customer’s DPF issues, resulting from a faulty MAP sensor.

A few weeks ago I received a phone call from a distributor’s customer asking for assistance as the Toyota he was working on had been emitting black smoke for a couple of weeks before going into limp home mode, with a fault code of P2463 (DPF restricted). He explained that he had replaced that DPF with a new EEC one two months ago, but unfortunately the same thing had started to happen again and he thought the new DPF was faulty.

He explained that he had checked all of the areas and components that could be the cause of the problem, air leaks, EGR valve, fuel injectors, turbo, etc. and all were working correctly. I suggested he checked the MAP sensor as I thought this could be the problem. Although there was no MAP fault code showing he still needed to examine the sensor to ensure it was clean, with no damage and functioning correctly.

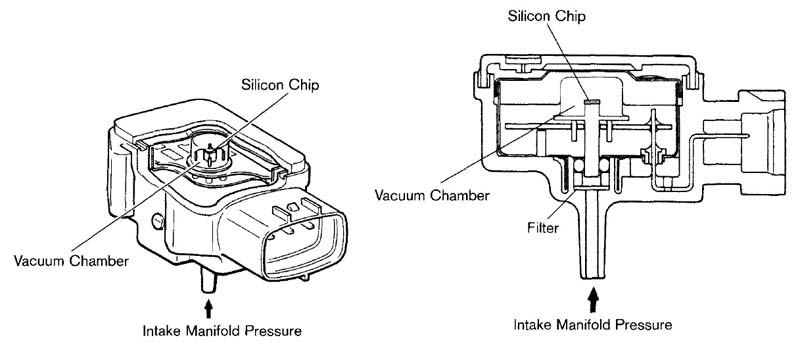

A MAP sensor reads the amount of air pressure in relation to vacuum inside the intake manifold, either directly or using a vacuum hose, it then translates this pressure into a voltage signal sending it to the power control module (PCM).

The sensor uses a 0-5 volt reference signal, a change in vacuum or air pressure in the intake manifold varies the electrical resistance in the sensor, increasing or reducing the signal’s voltage to the computer.

The PCM uses the MAP sensor’s information along with input from other sensors to adjust fuel delivery to the cylinders and ignition timing according to current engine load and speed. This can upset fuel delivery and ignition timing.

Depending on your vehicle model, your engine might experience one or more of these performance problems:

Signals of a bad MAP sensor including: rough idling; sluggish acceleration or hesitation; poor fuel economy or black smoke.

An underperforming MAP sensor can lead to an increase in harmful PM. excessive fuel generates higher hydrocarbon (HC) and carbon monoxide (CO) emissions, while insufficient fuel may lead to higher nitrogen oxide (NOx) emissions.

Troubleshooting a sensor is a straightforward procedure using a digital multimeter (DMM) and a hand-held vacuum pump.

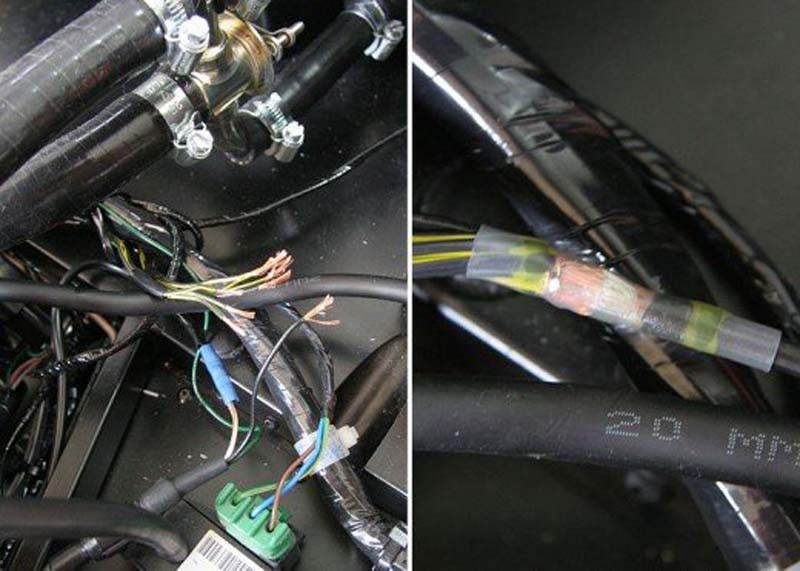

Always inspect the map sensor wires for damage during your diagnostic.

Just because there is not a MAP fault code does not mean all is OK. It could be faulty and still working but not correctly. By sending the incorrect data to the ECM, generating more PM/carbon, topping the DPF regeneration process, could result in a blocked DPF.

The MAP/MAF sensor is an essential part in delivering the correct fuel/air mixture to the engine. If it fails or begins playing up, the ECM cannot function properly, and neither will the engine.

To ensure your engine works at peak performance, it’s sensible to keep your MAP sensor in good condition.

Check the sensor’s wiring and connector. It should be connected securely, and the pins free of dirt and undamaged. Bent or corroded pins will also adversely affect the sensor signals. The wiring from the ECM to the MAP sensor should also show no signs of damage. Wiring that is damaged can cause short circuits.

If the MAP sensor is linked to the intake via a hose, check it is not damaged. Check the port is clean and unblocked as this can lead to unreliable readings.

If the sensor checks are ok, the next step is to try a scan tool or voltmeter and vacuum gun to gauge the sensor’s output. Check the voltages you need to see for full and no vacuum. If you don’t get the correct readings, the sensor will need replacing.

With no information from the sensor to work with, the ECM will assume the engine is under a high load. A failing MAP sensor tricks the ECM into believing the reading is low or there’s no vacuum. Consequently, the ECM fires in extra fuel and advances the spark timing to compensate, resulting in increased fuel consumption.

As a conclusion, the customer replaced the faulty MAP sensor which solved the problem.