Dayco talks about the latest developments in belt technology and offers its advice on how best to handle replacements.

As an established power transmission system expert, Dayco is a preferred partner for many vehicle manufacturers and its expertise has enabled it to develop highly efficient solutions for their many and varied needs, particularly as they endeavour to meet the emissions targets demanded by governments around the world.

Among these many product developments, and one that will be very familiar to technicians in workshops across the country, is the Dayco High Tenacity (HT) or ‘white’ belt, which, with its PTFE film on its inner teeth and fibreglass core, has become the mainstay timing belt for many engine variants used for multiple applications by numerous vehicle manufacturers.

Just as the constant evolution of engine design led to the development of new materials that are able to guarantee higher performance levels, like those used in the manufacture of Dayco HT belts, further advances have raised the bar still higher.

Dayco HK belts, originally designed for the requirements of specific Peugeot/Citroën applications, encompass the highest level of technological development and feature a tooth lining fabric and weave that incorporates aramid fibres. This combination achieves extremely high wear performance and greater adaptability to tooth geometry, which makes them particularly effective for high-stress transmission systems.

Other notable solutions include the belt-in-oil (BIO), a technology that Dayco originally developed to drive the high pressure fuel injection pump for Ford’s 1.8-litre ‘Lynx’ engine, and which has subsequently been used in several other applications, but where space is of particular concern, the company has produced a double-sided timing belt.

Another development is the Dayco belt-start generator (BSG) 48 V, a stop/start hybrid engine system designed to enable torque to be transmitted in different directions. The BSG is an unorthodox alternator system that, as well as charging the battery when needed, provides engine starting and braking energy regeneration through the alternator, via the auxiliary belt.

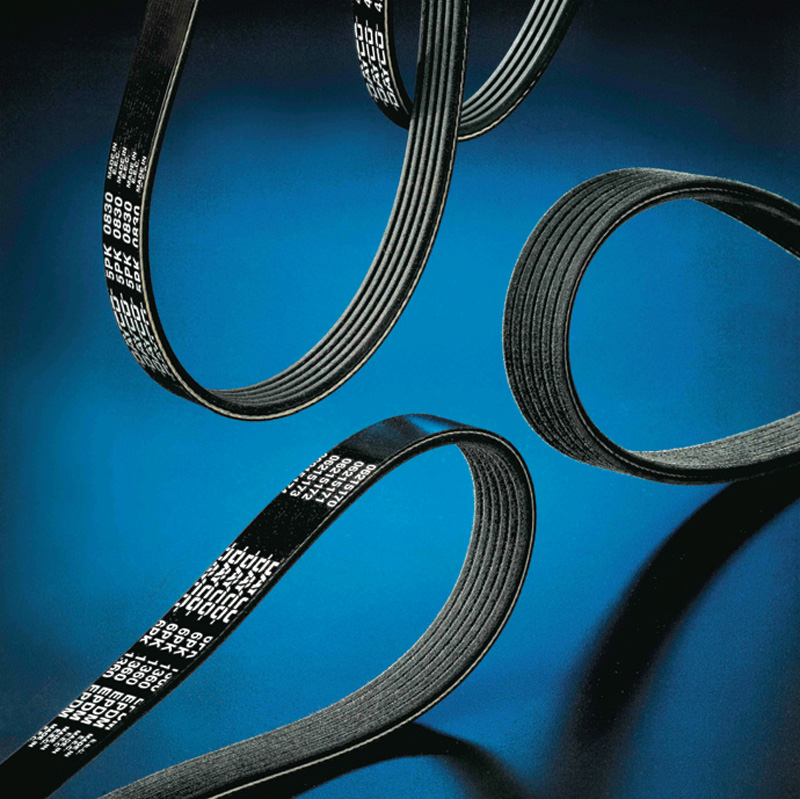

The Dayco Poly-V belt for this system, which has a white, high-strength fabric coating the rib side, is particularly durable and designed to operate in winter temperatures of minus 40°C and then be subjected up to 90°C within the engine department.

Check & Change

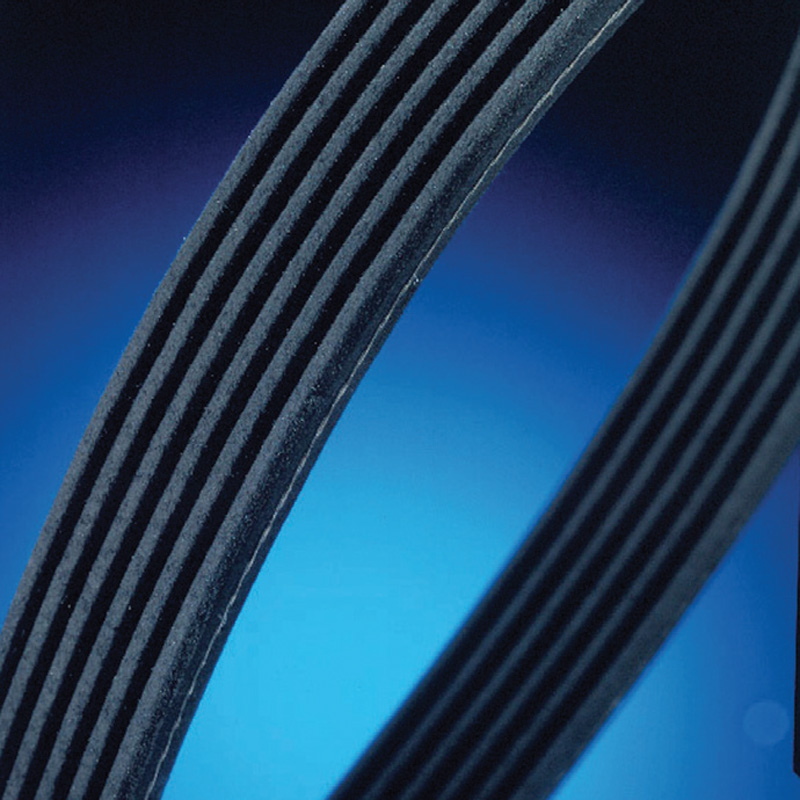

Unlike the previous generation neoprene rubber based auxiliary belt, the EPDM formulated belt used nowadays, wears very differently. So whereas during use, the previous technology would gradually lead the belt to perish by cracking or chunking – when a section of belt actually comes off – the current EPDM technology belt wears gradually, not unlike the wear to a tyre, which actually makes it more difficult to detect.

As a result, technicians should use the vehicle’s mileage as their first point of reference, which means that if the vehicle has covered 60,000 miles or more, the belt should be thoroughly inspected and if it shows any sign of damage or wear, should automatically be replaced.

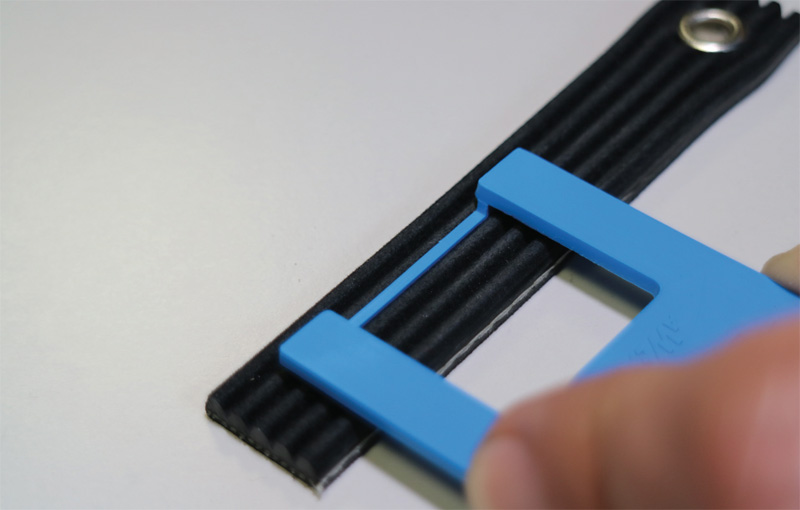

To help technicians correctly assess the condition of the auxiliary belt, Dayco has designed the aWEARness gauge, which provides them with three ways to check whether the belt needs to be replaced or is okay to be reinstalled. The two most relevant to an EPDM belt are the wear indicator bar, which highlights material loss and the profile indicator, which reveals whether the belt retains its correct form. Both reflect the level of wear and if the belt fails either check, it must be replaced.

Wear on the belt could also indicate wear to the other components in the auxiliary drive system, which is why technicians also need to thoroughly assess the condition of these associated parts. Particular attention should be paid to the tensioner, because, in common with the timing drive system, the wrong tension on the belt can exacerbate wear and contribute to the potential failure of the drive system.

Dayco provides a ‘one-stop’ solution for auxiliary system maintenance and replacement because, in addition to its original equipment (OE) designed belts, it also manufactures tensioners, pulleys and dampers, which means that technicians have the assurance that they are installing fully compatible parts. With torsion vibration dampers (TVDs) and water pumps also included in the Dayco offering, its auxiliary drive package is complete.

Technical Tips

There are numerous tips that Dayco recommends technicians bear in mind to promote best practice when replacing primary and auxiliary drive components; amongst others, these include:

- Ensure the engine is cool, ideally not run for at least four hours

- The working area air temperature should be around 20°C, the same as the parts to be installed

- Disconnect the battery

- If needed, remove the spark plugs

- Only rotate the engine in its normal operating direction

- Ensure that replacement belts are treated with respect and not handled with greasy hands, crimped or otherwise damaged before installation

- When fitting a replacement water pump, sealing compound should only be used when the gasket is not included, otherwise just wet the mating surfaces and the supplied gasket with coolant

- As Dayco kits contain all the components that manufacturers state must be changed in accordance with the specific service procedure, technicians must fit all the components supplied in the relevant Dayco timing or auxiliary belt kit, during the replacement process

- Specific torque sequences and values must be followed

In short, the basic principle for technicians is to simply follow the original manufacturer’s instructions, without adding ‘just in case’ additions like lots of sealer or thread adhesive etc. In other words, don’t improvise and fit it the way they think is best, just follow the directive, which is best.

Free tool

As a further step to help technicians check the condition of the auxiliary belt, while stocks last, Dayco is offering workshops a free aWEARness gauge, which they can get by simply contacting their Dayco stockist and requesting one of the useful tools.