Here, GYS’ Neil Pulsford explains the latest developments in Battery Support Units and what technicians need to know about this part.

Car makers first started using Battery Support Units in the mid-to-late noughties. The first units were low powered, perhaps 25amps and had little or no functionality, you switched it on or you switched it off.

The requirements for battery support are now widely understood, technicians are aware of the electronic loading that a vehicle can place on the battery when the vehicle is in a ‘key on, engine off’ condition. With a vehicle drawing 20 Amps, or 40 Amps or even 100 Amps, a typical 60 or 70Ah battery will be unable to sustain that demand for more than a few minutes before the voltage drops, with the result that the electronic control system in the vehicle starts to run into difficulties.

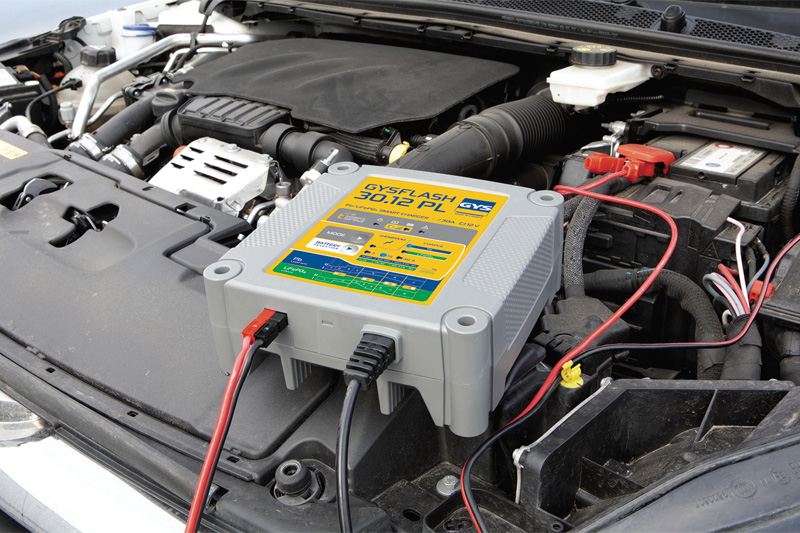

Whilst we know the products as Battery Support Units, they are really ‘voltage stabilisation units’. During diagnostic or programming work on a vehicle, the critical element is that the voltage operating in the vehicle is at both a sufficient level, typically 13.5V or even up to 14.8V on some vehicles, and that the voltage is constant and stable.

Due to the power consumed by the vehicle, the battery cannot sustain the electronic system for long so the Battery Support unit takes over. It performs two functions for Battery Support, maintaining the voltage at the set level and instantaneously providing current to the vehicle to match the current draw at that moment.

Without even considering alternatively fueled vehicles, the increase in complexity of the electronic systems on ICE cars over the last 10 years has been transformational. This has resulted in car makers specifying ever more output capability to support vehicles during programming, now 100 Amps is typical, also 120 Amps. Considering that to charge a battery typically around 7 Amps is what is needed we can see that 100 Amps is at another level.

Though GYS is now the largest manufacturer of battery support units, much of the functionality expansion of the product comes from the car makers. Consequently, last year the company launched the GYSFlash 121 CNT – CNT denoting ‘connected’ – which not only raised the output to 120 Amps but opened up comprehensive connectivity to the product. These units now offer future upgradeability as new software is developed and the ability to record the charge data.

As well as increasing energy demands for the vehicle, the occasions when battery support is essential are also expanding. Originally for basic diagnostic and programming tasks, including service resets and electronic hand brake adjustment, now we see windscreen replacement needing programming and battery support. The proliferation of ADAS and its maintenance now requires the windscreen and bodyshop sector to be as engaged as the mechanical sector as to the battery support requirements.

Such is the demand for battery support for today’s vehicles it makes sense to connect all vehicles to support almost regardless of the work required. To this end Battery Support Units are now available that fit to the vehicle lift. Workshops fitting new lifts may want to consider this at the time of installation to simplify connection to the mains supply.