Straightset outlines how you can effectively use wheel clamping systems during wheel alignment.

In the garage, precision is paramount. When it comes to wheel alignment, the importance of precise measurements cannot be overstated. Enter the unsung heroes of this crucial operation: wheel clamps. These unassuming, yet essential, tools come in various shapes and sizes, each offering unique advantages tailored to different needs.

The choice of wheel-clamping device does play an important part of any wheel aligner and alignment process, especially with the suspension set ups on modern vehicles where accuracy is dependent on fitting the clamps correctly, performing the all-important run-out compensation as well as using a fully calibrated machine and accurately level lift platform.

Initially there was only either a 3-point or 4-point claw type clamp available, though as nearly all vehicles had steel rims this didn’t present any problems with potential damage that can occur if the fingers of the claw grips are themselves damaged or broken. With most of today’s vehicles having alloy rims as standard, solutions to the potential problem of rim damage, as well as speeding up the wheel alignment process, have been available for some years now with the introduction of different clamping styles. Here are some of the systems available today:

Hang on system

The hang on system, with no clamping and the use of rim buttons, made popular by Supertracker, eliminated any potential damage to alloy wheels and is still a popular choice amongst wheel alignment professionals today. This offers an alternative to a clamp system, and can cater to tyres from 12 inches to 24 inches.

Self-centring clamps

With advancements in product design, the self-centring clamp system, which has nylon feet that sit up against the rim with claws that wrap around to grip the tyre, are a very successful design which is still used today and available as an update to the Supertracker CCD system. These clamps automatically centre themselves on the wheel when applied, eliminating the risk of human error. This precision not only ensures more accurate alignments but also enhances the safety and performance of the vehicle and offer a solution to performing wheel alignment on lowered vehicles. With 3-point and 4-point clamps available, these are still going strong today and with suitable extensions that can be used on rims up to 28 inches in diameter.

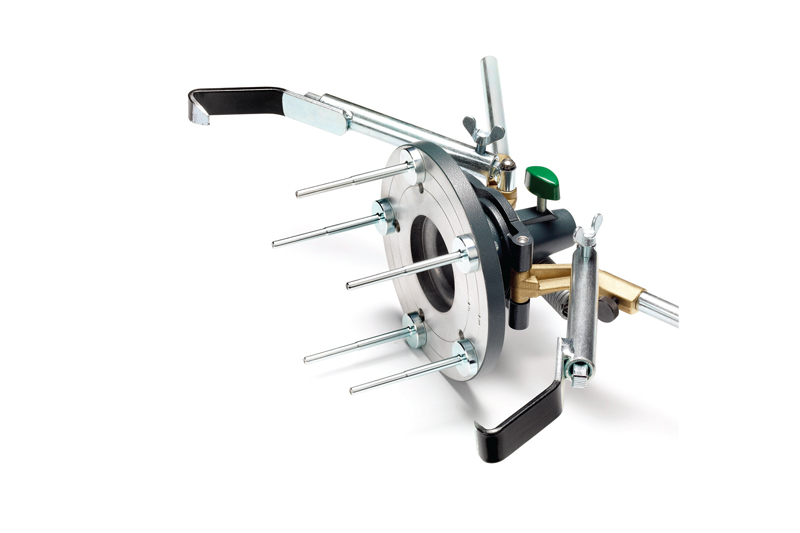

Specialist clamps

Some specialist vehicles and vehicle manufacturers require specialised attention and that includes for wheel alignment. As a leading wheel alignment manufacturer, Beissbarth, began to produce individual clamps for BMW and Mercedes Benz initially, which used pin sets to locate the clamp against the hub with wrap around claws to grip the tyre tread. This type of clamp ignored the rim and measured directly from the hub, allowing for the runout compensation to be skipped but still giving a very accurate measurement.

This spilled out to other marques who wanted a unique, and accurate clamping method, notably Porsche, Tesla, Ferrari, Lamborghini and very soon the JLR range, who have opted for centre mount devices, all machined to very fine tolerances to fit in place of the rim’s centre cap. There are variations of clamp depending on the model.

Magnetic clamps

With the introduction of the Beissbarth ML3D wheel aligner another advancement in wheel clamping was launched: the magnetic clamp. By using strong magnetic studs they affix to the vehicle’s steel wheel studs. This has proved to be a quick and easy clamp for the technician to use, less cumbersome than most other wheel clamps on the market.

Quick clamps

In today’s fast-paced world, every second counts. Q.Grip clamps are designed with efficiency in mind. Their swift application, courtesy of a lever mechanism, streamlines the alignment process. For busy auto shops, these clamps translate into faster turnaround times, increased customer satisfaction, and higher productivity. The latest product from Beissbarth is the Q.Grip, to complement the Q.Lign wheel aligner range.

These are a patented design and provide the technician with a very quick clamp that wraps around the tyre at three points and with the all-important run-out compensation performed have proved to be as accurate as all other clamping devices. Wheel alignment isn’t just about functionality; it’s also about aesthetics. Nonmarking clamps come to the rescue by using rubber or soft material pads to prevent damage to wheel finishes. For high-end or custom wheel owners, this means preserving the appearance and value of their investment.

In conclusion, wheel clamps may not be the first thing that comes to mind when thinking about automotive maintenance, but they are integral to achieving precise wheel alignments. Their diversity caters to various vehicles and needs, from quick alignments in a bustling workshop to intricate precision work on specific vehicle manufacturers. By selecting the right clamp for the job, auto technicians can ensure safer, more efficient, and more accurate wheel alignments, ultimately benefiting both customers and their bottom line.