Spark plug specialist NGK offers the PMM audience its advice on the most common spark plug issues.

UK workshops carrying out service and MOT work on their customers’ cars need ignition components they can trust… ones they can ‘fit and forget’.

NGK iridium spark plugs feature an iridiumalloy on the middle electrode. One of the world’s hardest metals, iridium starts melting at a temperature of 2,450˚C and is therefore very resistant to spark erosion. Consequently, the service life is doubled on average in comparison to standard nickel spark plugs.

Platinum spark plugs have a platinum plate on the middle electrode ensuring a more constant output of the spark plug over the entire service life, even under difficult conditions. Precious metal spark plugs may be more expensive, but when specified by vehicle manufacturers (VMs) and used during service and repair they will prevent possible problems due to:

- Poor ignition performances

- Poor tolerance to fouling

- Higher ignition coil loads

- Increasing unwanted emissions

Most issues in relation to spark plugs are invariably down to a plug being affected by either an engine running/set up problem or something that has gone awry during installation. The common ‘misfire’ complaint in connection with spark plugs is first tackled by plug removal and examination. Plug fouling can cause a misfire. This can be, for example, in the form of excessive carbon build up caused by an engine running in a rich condition, coated with oil due to an engine condition issue. Fouling will not be the fault of the plug itself provided the correct plug for the engine is installed.

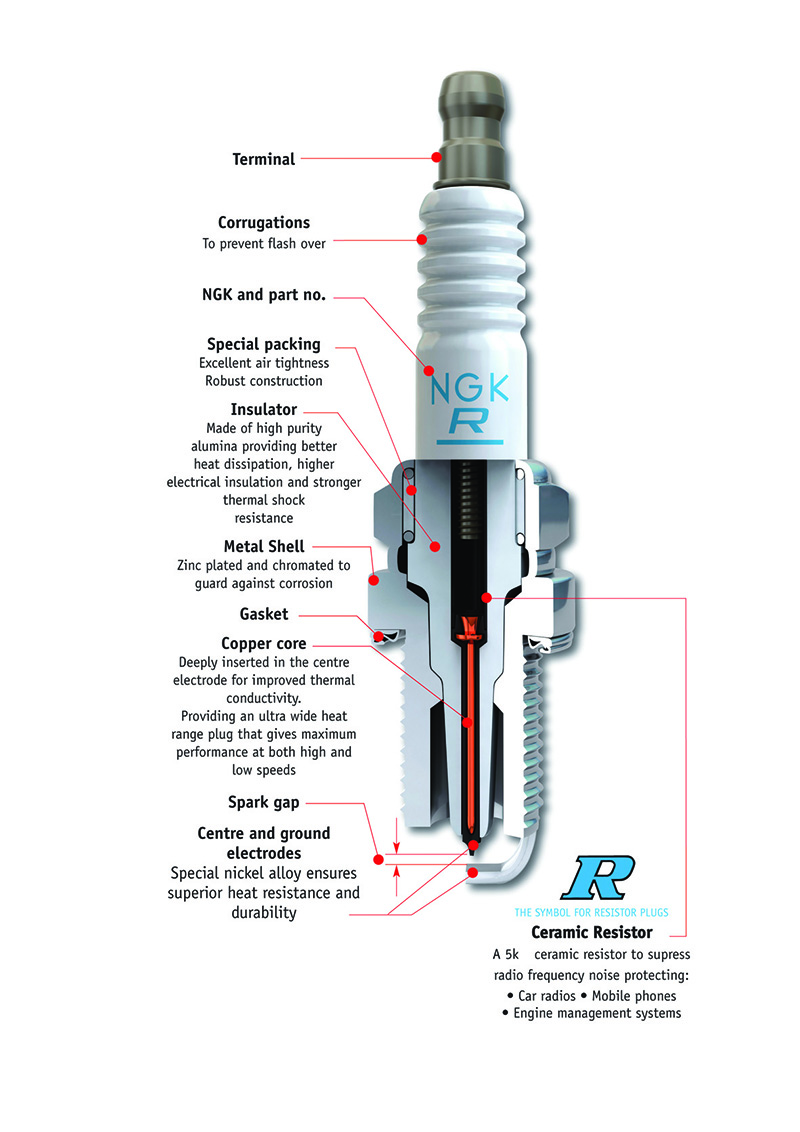

Closely inspect the plug insulator for cracks, which will cause a misfire due to the voltage no longer being contained. A crack to the top portion of the insulator is caused by either over tightening or the plug being tightened with the wrench canted out of line. This puts pressure on the top of the plug.

A crack in the insulator on the firing end is usually caused by ‘thermal shock’, the result of neat or poorly atomised fuel hitting the hot insulator surface causing it to cool rapidly.

Black vertical electrical lines on the white insulator surface (sometimes mistaken for cracks) are a sign of ‘flashover’. They can occur between the top terminal and the metal shell body. These are the result of a worn or deteriorated plug rubber sealing boot on the lead or ignition coil. Replacement of the plug alone may not cure unless the connection on to the plug is secure and the seal over the insulator is tight.

A broken plug metal shell is the result of over tightening. This occurs at the top of the thread or just above. There is no requirement to use any anti-seize grease on NGK spark plugs. Use either the vehicle manufacturers or NGK’s recommended torque. If the threads are not dry or an anti-seize grease has been applied, then do not torque, but use the tightening angle advice displayed on NGK spark plug packaging. Torque and tightening angle advice varies depending on the plug thread size, sealing method (taper or gasket seal) and varies between gasket material and construction types.