With Meyle, manufacturer of automotive spare parts, growing its brake disc product range, expert and technical trainer Michael Nowak shares advantages on the two component brake discs and tips on installing them in the workshop.

Meyle is expanding into the aftermarket for brakes with solutions in areas previously reserved for vehicle manufacturers with their original parts. Seven new references for the two component PD brake discs are now available for the BMW 3 to 8 Series, X3 to X5, and Z4, and for Mercedes C-Class and E-Class models. Therefore, the expert Michael Nowak, a technical trainer at Meyle AG, is giving his insights on the advantages of the new brake discs and what to be aware of when installing them in the workshop.

Advantages of two component brake disc systems

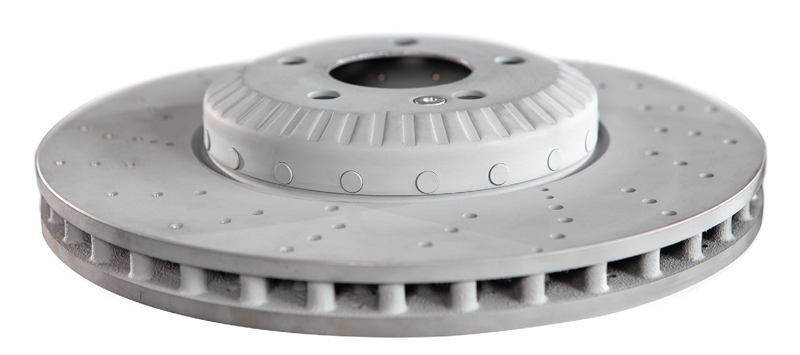

These special discs aim to offer a huge difference in comparison to normal one component brake discs. The main difference is that, instead of being made out of a single piece of cast iron, the hat and the friction hat are riveted together, combining a cast iron friction ring with a stamped steel or machined aluminum hat.

The separation of the friction ring from the hat allows for the possibility to use two different materials for one disc. The friction ring is still made of cast iron, but the hat can be produced of aluminum or stamped steel with a thinner wall thickness and lower weight. Thanks to the lower weight of the two component brake discs, there is a lower rotating mass. This leads to less energy/ fuel consumption, which makes the vehicle overall more efficient.

The Meyle engineers took all the OE specs into consideration when developing the two component PD brake discs, aiming to offer customers the usual OE qualities such as accurate fit through low offset, reduced weight and the associated fuel savings and decrease in CO2. At the same time, the new brake discs claim to boast high performance, driving comfort and sophisticated design, as is typical of the company’s line. In addition, they are ECE-R90-certified and, due to the high-quality surface coating, claim to not require degreasing, thus ensuring long-lasting protection against corrosion.

A higher percentage of carbon is said to make the two component brake discs resistant to heat distortion, even in cases of higher thermal stress – for example, on steep mountain descents – for extended driving comfort without vibrations. To help ensure efficient installation at the workshop, 99 per cent of the brake discs are equipped with a fixing screw.

When and how to service?

Largely, the brake system is one if not the most important safety relevant system in vehicles. Two component brake discs as well as single component brake discs need to be checked regularly. Therefore, it is highly recommended to raise awareness with workshop customers for a regular vehicle service check.