To gain a better understanding of what it is to be a Schaeffler REPXPERT, PMM was invited to the Basingstoke College of Technology for Schaeffler’s second REPXPERT Academy LIVE training event. Here’s what happened…

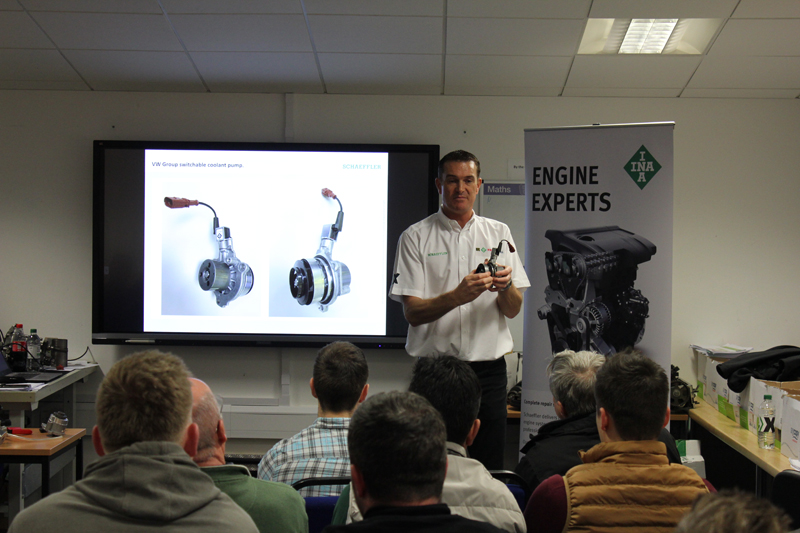

It is important to understand that the series of REPXPERT training events, aptly named REPXPERT Academy LIVE, has been created to supply UK independent garages with, first and foremost, information. At least, this is what Alistair Mason, one of Schaeffler’s REPXPERTs and a name many readers should be familiar with, explained in the first of the four sessions of the day: “We [Schaeffler] found that when we exhibit at trade shows and various other events, all technicians really look for and want is information. So, we came up with the REPXPERT Academy LIVE concept.”

These courses are spread throughout the year and across the country to try and appeal to the UK garage industry as a whole. It is both a meeting point and a forum of knowledge that brings technicians up to date on the latest developments in both Schaeffler technology and the automotive industry as a whole.

The day was split up into four separate sessions with breaks in between where delegates could spend time networking, checking out the REPEXPERT and Laser Tools vans, watching a Techman demonstration, or chatting to representatives from the college and IMI.

SESSION 1: Modern Thermal

Management Systems

Thinking back to the October issue of PMM you may remember an article that focused on the training available from Schaeffler on its INA brand. Although the content was similar, the thermal management session at the Academy LIVE event was far more in depth, catering to the technical needs of a professional automotive technician.

Alistair started the session by highlighting the key aspects of switchable water pumps, explaining what makes an INA water pump OE quality, as well as where it fits into the engine cooling system. He discussed why INA pumps use a plastic impeller, where the use of a vacuum comes in to test a water pump, and the possible implications of using replacement pumps that don’t match the original equipment specifications.

We then turned to thermal management modules, discussing everything from how to bleed the coolant system, to where the EGR valve fits in. Always willing to answer any questions fired at him, Alistair repeatedly relied on his extensive knowledge to provide answers to often specific queries and was very keen to encourage delegate participation.

Grahame Pells of GP Fabrications, one of the visiting delegates, commented on the session: “It’s great to have this information available and presented to you. Often, our only access to this material is on the instructions that come with the component. Now, I have it straight from the source!”

SESSION 2: Timing Belt Drive

Systems – Best Practice

After a short break to refuel on caffeine, the group moved on to the second seminar of the day. The timing belt drive systems session very much centred on the concept of the ‘4Ts’ and how to approach the general maintenance of the associated components. James Mainwaring, another Schaeffler REPEXPERT, took the session, running through the 4Ts associated with this product category and what technicians should be aware of when working in this area.

From Temperature and Tools, to Torque and Tension (yes, you guessed it, the 4Ts), the hour was a constant stream of best practice guidance, all of which adhered to the principle: “The timing belt is only as good as the metalwork and the installation.”

SESSION 3: Double Clutch

Systems & Repair Solutions

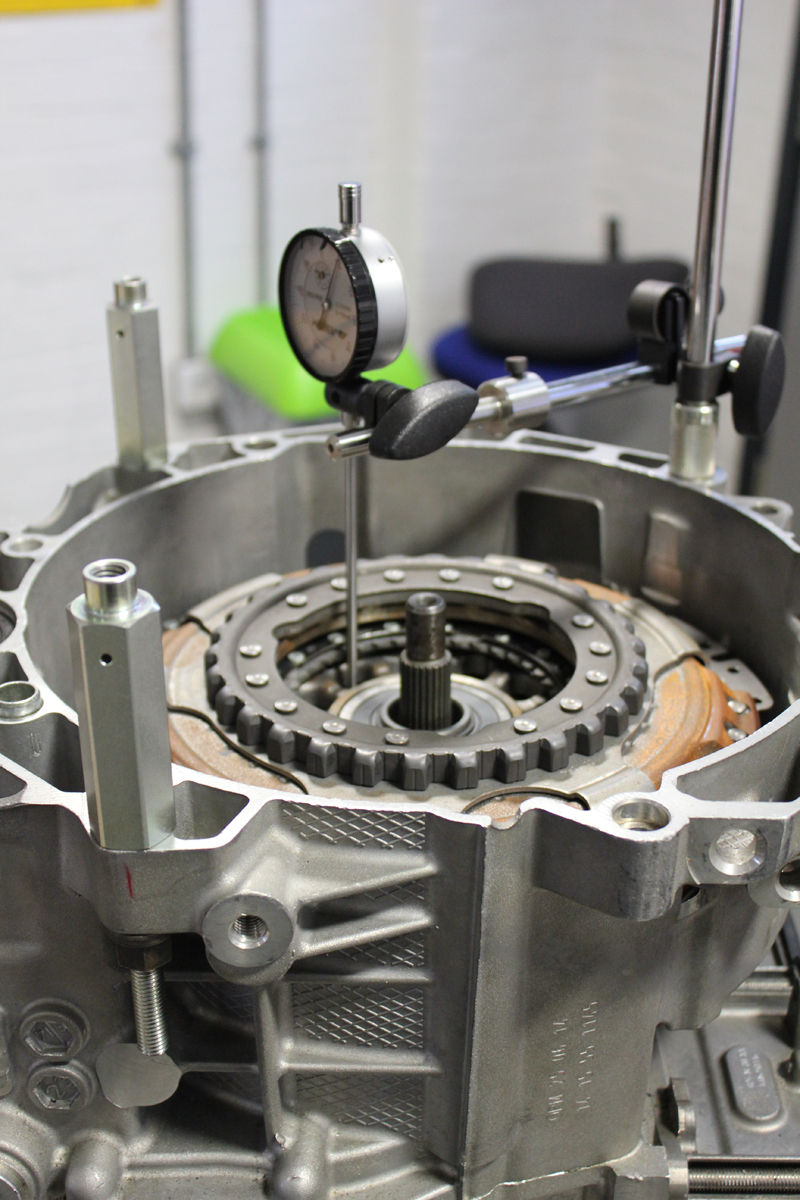

The final of the component-based seminars was overseen by Simon Cooper, another REPXPERT stepping from the ranks, and primarily composed of a step-by-step run-through of a LuK double clutch replacement.

At this point, it is important to mention that Schaeffler has been working with Laser Tools to develop affordable tooling that goes hand-in-hand with Schaeffler’s component brands. In this particular instance, Simon utilised a number of tools and kits to demonstrate the removal and replacement of a double clutch, explaining as he went why these specialist tools are essential.

With a packed room, you might ask how everyone could see the procedure take place, but by using a camera that had been placed directly above the clutch plate assembly, the whole process was projected onto a larger screen for all to see.

SESSION 4: Empower Your

Workshop Business

To finish the day, Andy Savva, a.k.a. The Garage Inspector and Schaeffler brand ambassador, delivered his well-versed and engaging presentation on how to manage and grow a garage business. The hour was filled with anecdotes and advice taken from Andy’s own experiences running a successful independent garage, with the man himself happily taking any questions from the audience.

Touching upon his adopted philosophies of Kaizen Lean and the 5Ss, Andy explained why organisation and reducing waste (things like unnecessary time wasting, workshop layout, etc.) could turn a business around. He presented before and after photos from workshops that he has visited, and how, simply by adopting organisational practices, you can change a business’s trajectory.

What the technicians say

For technicians that want to make a difference to their business, it is well worth the trip, as Dean Peters of DMG Autocare explained, “I can see REPXPERT Academy LIVE growing into a sought-after event, complemented by the fact it is free-of-charge. I’ve never attended an event as good as this for free!”