Suspension specialist KYB takes a closer look at what makes a quality suspension system and why it’s so important to ensure the selection of quality components.

First and foremost, a good suspension system must always meet the demands of the driver. For most drivers, standard suspension is well-suited to their needs. However, depending on what a vehicle is used for, standard suspension isn’t always the best fit. For example, it wouldn’t be of benefit to a sports car driver, or someone used to driving in off-road conditions to have standard oil shock absorbers. Instead, they would need a shock absorber with technology that allows for more response and control to accommodate their driving habits. This is why KYB has a number of different ranges available for purchase, enabling workshops are then able to select the best fit for their customer.

Quality vs budget

Not only will a good quality suspension component give you optimum safety and comfort, but it will also provide something economically beneficial to a motorist – longevity. Simply put, a good quality suspension system will last much longer than those manufactured poorly, especially those made using cost cutting measures.

For instance, take coil springs as an example. As a key component in a vehicle’s suspension system, coil springs are designed to withstand exceptionally high levels of stress as they work to support the weight of a vehicle. As is the case with suspension components, coil springs naturally wear over time the more they are used – they often become fatigued, causing a vehicle to sag on one side creating uneven ride height.

Corrosion is by far the most common cause of failure. Naturally exposed to the elements, stones and debris can chip away at the coating of the spring, allowing water and salt to rust the exposed steel, eventually causing failure or breakage.

Manufacturers like KYB use processes which aim to provide the best possible protection from corrosion and premature breakage, such as hot and cold coiling technology to strengthen the steel and improve durability, as well as a zinc phosphate coating and epoxy powder painting.

High quality, premium wire is also used to manufacture the springs with the aim of preventing premature breakage. Often littered with numerous surface defects, springs manufactured with lower quality wire are significantly more likely to break prematurely than their high-quality counterparts.

To demonstrate this, KYB recently commissioned testing of both KYB springs and those of a low-cost competitor. When compressed a million times, it was found that the budget springs compressed an average of 183,000 times before breaking completely. By contrast, the KYB springs survived the million rounds of compression.

Whilst buying a cheaper part may seem the most economical decision at the time – especially due to current financial conditions – it’s very likely that this choice will eventually cost the motorist more in the long run, as they’re forced to replace these suspension components prematurely. Not only does this cause issues for the motorist, but also for the workshop too as if the parts fail quickly, that could potentially lead to unhappy customers.

If fitted properly and driven in normal conditions, good quality coil springs and shock absorbers should last for at least 50,000 miles.

It’s what’s on the inside that counts

If you compare a shock absorber manufactured by a premium manufacturer and a shock absorber manufactured by a budget brand alongside one another, the chances are that it will look the same at first glance. However, it is often beneath the surface where there are noticeable differences that help to explain how the performance of a shock absorber can be directly affected by the use of poor-quality materials.

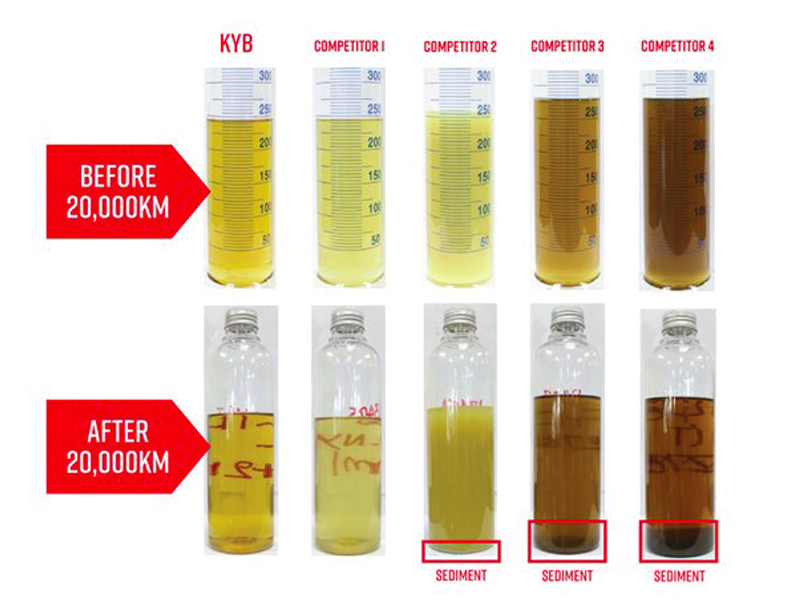

To understand this, KYB conducted research using five identical cars, each of which were fitted with a set of shock absorbers manufactured by different brands: KYB, a premium competitor and three low-cost competitors. Each vehicle covered over 20,000km on the same circuit, simulating every possible driving condition. The shock absorbers were then removed, and the insides inspected. As is evident from the image below, there are clear differences between all five oil samples. The fluid in KYB’s shock absorber is much clearer than all other samples, which are either darker in colour or cloudier, with three of the samples showing that sediment had contaminated the hydraulic fluid after 20,000km.

How can I ensure that the product I buy is high quality?

- OEM manufacturers. If vehicle manufacturers trust a supplier to manufacture parts for their vehicles, you can be sure that it’s high quality.

- Check for quality certifications.

- Warranty. If a product comes with warranty, the manufacturer is assuring that you’re going to get your money’s worth. Be careful though – many manufacturers will limit the mileage that you’re allowed to claim warranty for. KYB product comes with a 2-year unlimited mileage warranty.

Usually, there are two reasons for the presence of sediment within the oil: the quality of the oil itself and the level of precision in manufacturing of the shock absorber, especially relating to the shock absorber seal. A shock absorber seal is specifically designed to prevent any internal fluid and gas from leaking out, as well as preventing any contaminants from getting in. Samples 2, 3 and 4 indicate that the seal has been compromised, allowing dust and debris from the external environment to collect within the oil of the shock absorber.

This will directly impact the effectiveness of a shock absorber in two ways;

- Debris within the hydraulic fluid is likely to cause further damage to the seal, allowing the oil within the shock absorber to leak out, causing premature wear/failure of the shock absorber.

- The damping force of the shock absorber is significantly reduced, making for a less comfortable ride and compromised safety. As a shock absorber compresses and decompresses, hydraulic fluid is forced through several finely tuned valves within the body of the shock absorber. The presence of debris means the fluid passes less easily through the valves of the shock absorber, leading to a decrease in effectiveness.