Suspension specialists Arnott investigates the growing demand for air suspension among drivers.

Arnott’s engineering team thoroughly investigates the original construction and design and looks for possible engineering or quality flaws during the development and testing phase. If present, the design is adapted and improved to eliminate those. After the development stage is finished, the product undergoes extensive road-testing on its own fleet of vehicle, durability testing, and burst testing to prove it meets the highest standards.

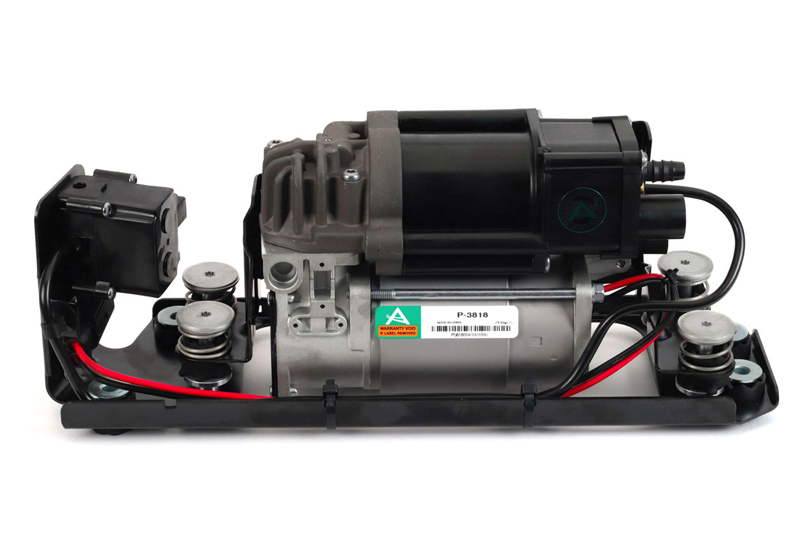

On the quality side, one of the key components is the rubber used for the air sleeves. Rubber is subjected to wear and tear and therefore it is important to use high quality rubber to ensure longevity of the part. That is why Arnott only uses elastomer from respectable OEM manufacturers so that the sleeve construction is made with high quality elastomer material and consists of a five-layer multi-ply design to provide a long-lasting structural integrity. Arnott’s designs often enable easier or fail-safe installations, for example most Arnott products come with preinstalled Voss-connectors for an easy push-in air line connection eliminating the chance of over-tightening the connector which causes leakage because it damages the screw thread. In addition, in Arnott’s range are easy “plug and play” air suspension compressors which come fully assembled including the brackets and solenoid valve.