Jurid recommends certain winter safety checks to help customers avoid falling foul of treacherous winter driving conditions.

The Great British weather is always a talking point and recent years have thrown up some extreme and unexpected conditions. A safe prediction we can make is that winter will bring with it harsh cold-fronts and plenty of rain. At times, driving will be treacherous and the brakes on every vehicle in the country will be put under pressure to deal with difficult and adverse conditions.

It will be no surprise to readers that there is a clear trend of increased collisions following the October clock change with darkening afternoons and worsening weather being significant factors, according to the RAC Foundation. Poor visibility and increased stopping distances mean a well-maintained braking system is, and always will be, safety critical.

Take action early

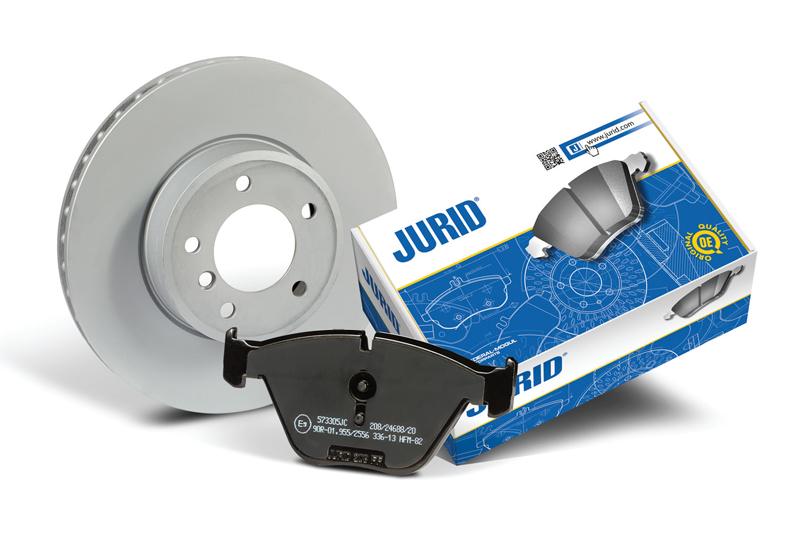

Jurid recommends that garages should take the initiative by promoting ‘Winter Safety Checks’ to help customers avoid falling foul of difficult seasonal conditions. Customers need to be reminded well ahead of time to book in for preventative maintenance with brakes at the top of the agenda of any winter service.

The braking specialists at Jurid have shared some useful hints and tips in spotting when brake pad problems are likely to occur and how correct brake maintenance over the winter period can make a marked difference in safety.

Worn out pads

As a starter, it is essential to inspect brake pads for an idea about their general condition and whether they have sufficient service life to provide efficient braking over the winter months.

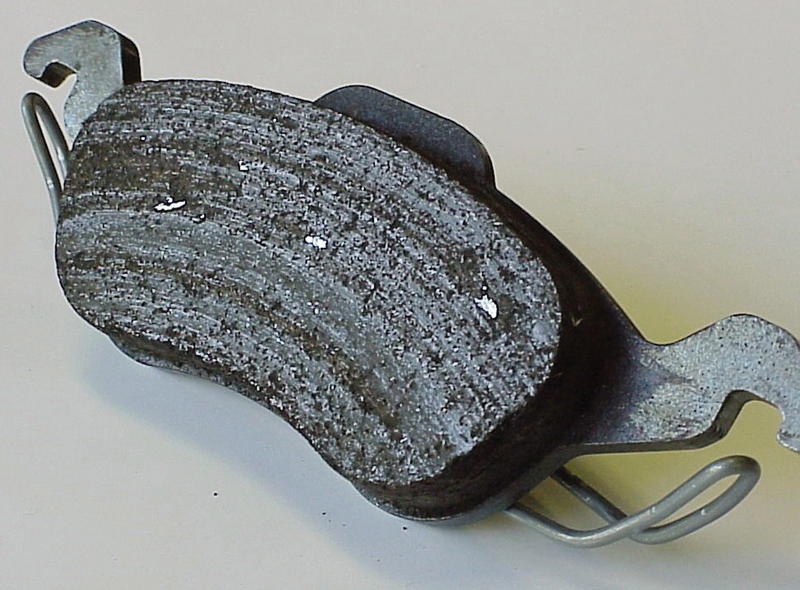

Pad wear itself can often reveal a lot about the brake system as a whole. For instance, ‘lipped’ wear on the pad surface will reveal an irregularly worn brake disc. Such cases point to further diagnosis of the brake system.

Tapered or uneven pad wear can indicate a distorted caliper, excessive caliper clearance or the caliper slides and piston sticking. Here, the driver will experience uneven braking together with excessive noise and squeal.

Insufficient periodical inspection of pad wear can lead other more costly repairs such as damaged discs not to mention uncomfortable experiences for the driver such as unpredictable braking or a vehicle pulling to one side.

A sticky issue

‘Denaturing’ of brake pads results from prolonged excessive pad temperatures due to intensive use, dragging or calipers sticking. It can be diagnosed by spotting whitish outer edges on the brake pads which is an indication of partially charred friction material. In severe cases the result is a reduction in initial braking efficiency and deterioration in the braking material which then becomes brittle and is prone to breaking apart. If the ‘denaturing’ is severe then pads should be replaced and in all cases inspection and service of the brake caliper using an antiseize grease during assembly is recommended to avoid further problems.

More serious implications of a poorly maintained brake system would be cracking of the friction material which can occur when the pads are not free to slide in the caliper. The piston will bend the back plate with the cracks caused by flexing due to pads sticking in caliper. Caliper service, using an anti-seize grease during assembly and pad replacement are the only remedies in such cases.

Bedding-in problems

Assuming you have fitted new brakes to a customer’s car they will benefit from good advice about bedding-in new brakes. Jurid recommends braking lightly, but often, for the first 200 miles after new pads have been fitted.

This simple advice can avoid problems such as ‘surface glazing’ caused by high intermittent pad temperature, usually the result of excessively harsh braking during the bedding-in period. Glazing can bring a temporary reduction in braking performance and in severe cases pads will have to be replaced if performance is not remedied through normal use.

Similarly, metal pick up on the pad surface is an indicator of heavy braking on poorly bedded brake discs. Water ingress, ‘quenching’ of the disc causes disc fragments to break away, transferring them to the friction material which in itself usually has no detrimental effect on braking performance but may cause disc damage or brake squeal. However, in extreme cases, both pads and discs will need to be replaced.

Importance of prevention

Good practice ahead of the winter period should include a full check of the braking system, including service of calipers and where necessary the replacement of pads and discs. Brake fluid levels should also be checked and replaced according to the vehicle manufacturer’s recommendations, usually about every three years due to its hydroscopic nature (water content).

Jurid is a leading supplier of Original Equipment braking and prides itself on the highest levels of quality assurance. This comes from decades of experience working with the world’s vehicle manufacturers to develop original equipment (OE) brake pads and shoes that match the performance requirements of vehicles exactly.