When brakes are applied, the last thing you want is to hear excessive squealing or to feel unexpected vibration or judder. If vibration occurs, some technicians may jump to the conclusion that the disc is warped and needs replacing, but it could well be brake judder. Juratek explains how to spot and prevent this issue.

So, what is brake judder, and how can it be avoided? Brake judder can be categorised into two types: hot brake judder and cold brake judder.

Hot brake judder

Whenever you bring two surfaces into contact at high speed, the result is friction. This friction then creates heat, which is transmitted to other parts of a car’s braking system.

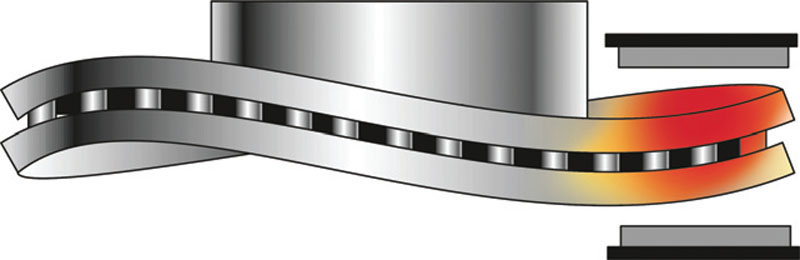

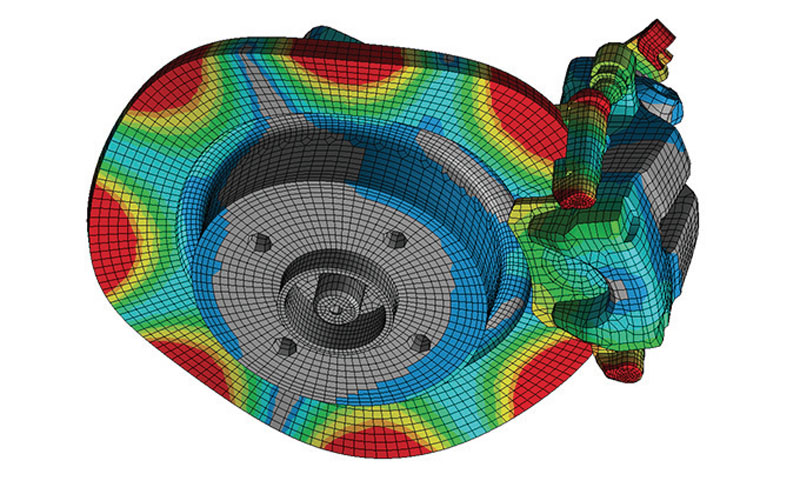

Brake discs are usually made of cast iron. When this material gets hot it naturally expands and distorts and returns to its original shape when cool. Brake discs are designed to handle this, and can operate in temperatures up to around 500°C. If the brake discs exceed the normal operating temperature, however, hot brake judder can occur as a result (Fig 1 and Fig 2).

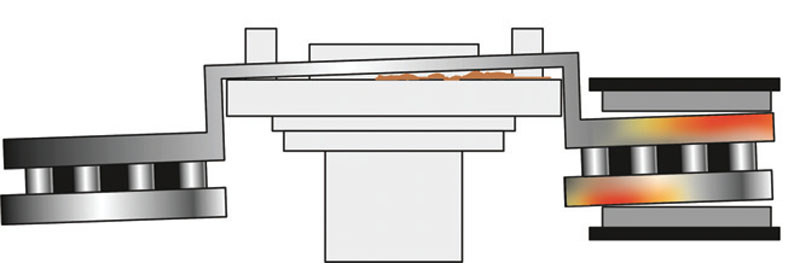

Fig 3 shows a disc that has several indicators of disc thermal distortion and excessive heat, including oxidation (orange), and a large radial crack where excessive heat has caused permanent damage.

What causes excessive heat?

The most common cause is abuse. Brakes are designed to withstand high temperatures and cool down quickly. However, if they are hit hard several times in quick succession this can cause a phenomenon known as ‘brake fade’, which is when the brakes get so hot they fail to work effectively.

Alternatively, the brake caliper could cease to function properly, causing the brake pad to remain in contact with the disc even when not braking. Heat will steadily increase and may eventually get so hot the brake disc will crack if rapidly cooled.

Cold brake judder

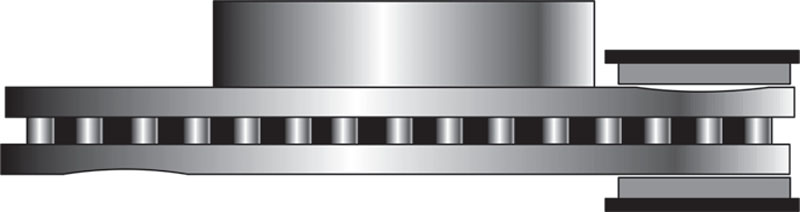

Cold brake judder is almost always a direct result of a fitting problem between brake disc and hub. Brake discs and hubs are manufactured to strict tolerances, which means any rust or other debris that can cause fitting issues (Fig 4) needs to be removed prior to installation.

If the disc is installed with excessively high levels of radial run out, there will be continuous contact between the pad and disc at diametrically opposite points on the disc face in the ‘brakes off’ condition.

With increasing mileage, this results in a progressively larger, localised variation in the thickness of the disc.

To ensure this does not occur, follow these steps:

1. Clean the hub of rust or debris

2. Check the hub for run out using a dial gauge

3. Install the new disc and then check using a dial gauge mounted close to the outer radius of the disc; the installed value of radial run out should not be greater than 100 microns, and ideally no more than 70 microns

Poorly manufactured brake discs can also cause brake judder. This can be detected immediately upon fitting, but most reputable brake disc manufacturers are now manufacturing to the strict regulations imposed by UN ECE R90:02, which in part covers the way a disc is manufactured as well as the composition of the material used.