Denso details how using modern spark plugs is crucial in the fight against emissions.

Vehicle manufacturers design the vehicles in their ranges to meet the environmental regulations of the country they are sold in at the time of their registration, which means that often their older models will have met older regulations, and are therefore less environmentally friendly than their current counterparts. However, enhanced replacement parts, such as advanced spark plugs, can help to bridge the gap between the original and current regulations, and allow the engine to run more efficiently and deliver improved performance.

The automotive industry has been working for some time to reduce internal combustion engine emissions in line with regulations and in the European Union (EU), Euro 1 emissions standards came into effect in 1992, marking the first universal standards for newly registered vehicles. This was an important step, but the Euro 1 requirements – including fitting a catalytic converter and switching to unleaded petrol – now seem quite basic.

Since then, there has been significant progress, and today the sixth generation of standards – Euro 6 – is in effect. These cover several different emitted pollutants, including carbon monoxide, hydrocarbons, nitrogen oxides and particulates, and conforming to Euro 6 will also reduce a car’s CO2 emissions and general running efficiency. (This is important as the EU, and the UK, has implemented CO2 emissions targets for new cars: 95g/km, equivalent to 4.1L/100 km for petrol or 3.6L/100 km for diesel cars).

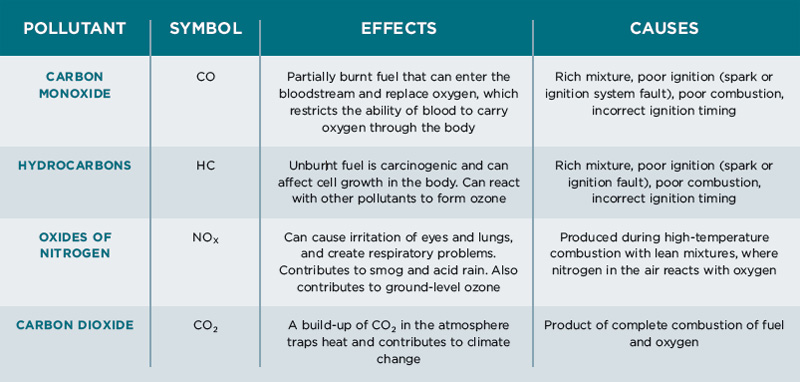

The main emitted compounds of concern are summarised in the table below.

Several engine components and processes can cause or reduce emissions, depending on how well they function. Therefore, improving engine design to find new efficiencies, and making improvements to ignition and fuel systems, has become a focus for the industry. This is why, when technicians are replacing parts during normal service and maintenance, it is recommended they use modern parts that benefit from improved technology, as opposed to the original standard of parts that were fitted to the vehicle at the time of its manufacture.

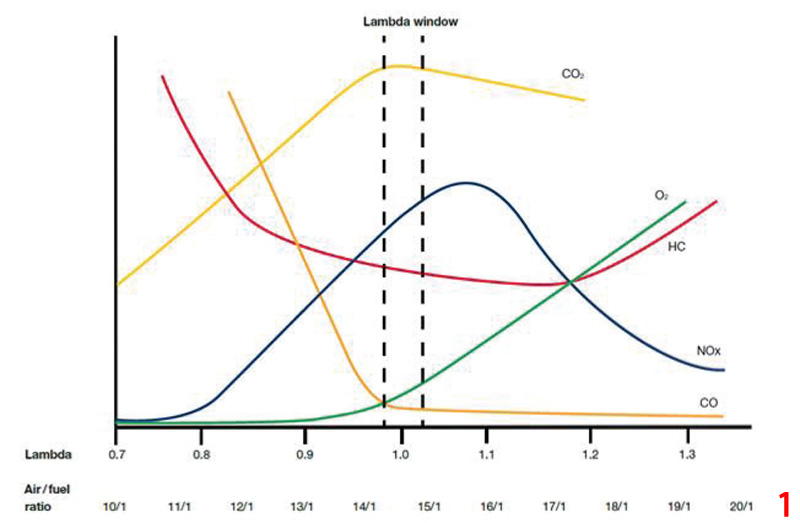

The graph in Fig. 1 shows the changing ratios of main pollutants and oxygen in exhaust gas. It illustrates how even small changes in the air/fuel ratio can noticeably increase or decrease the levels of pollutants.

When the air/fuel ratio is kept within the lambda window, a reasonable compromise is achieved between the different pollutants.

However, with new developments in engine technology, it is possible to further reduce emissions of some compounds, especially CO2.

Reducing emissions

Spark plugs transfer ignition energy into the combustion chamber and create a spark between the ground and centre electrode, igniting the air/fuel mixture. They operate within a volatile atmosphere with high fluctuating temperatures. Therefore, spark plugs are one of the key ignition components in petrol, compressed natural gas (CNG) and liquid petroleum gas (LPG) engines, determining exactly how much fuel gets burned in the combustion cycle.

Referring back to the previous table, a correctly timed spark and ‘clean’ combustion is associated with reducing emissions of a number of pollutants.

However, over time, spark plug electrodes wear, increasing the ignition voltage required for them to work properly. Eventually they may reach a point at which their ignition voltage demand is not supported by the ignition coil, potentially leading to misfires.

Increased misfires are directly correlated to increased emissions, since the air/fuel mixture doesn’t combust correctly, and make the vehicle operate less efficiently.

Technology update

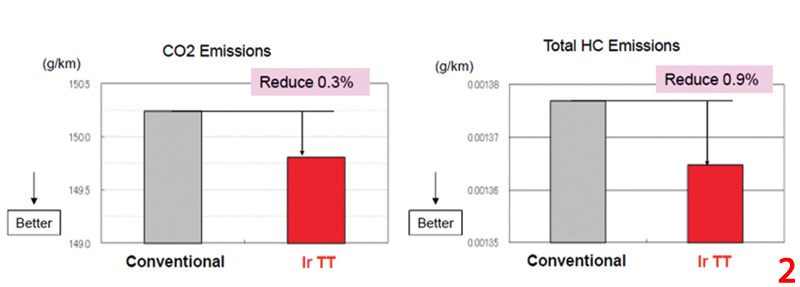

To minimise the risk of spark plug faults, workshops should fit spark plugs that match original equipment (OE) quality and, when servicing an older vehicle, opt for a version incorporating newer technology than the OE part. This is because, as can be seen in Fig. 2, Denso Iridium TT twin tip spark plugs achieve a reduction in CO2 and hydrocarbon emissions, when compared to a conventional spark plug, in a standard test vehicle.

Denso encourages workshops to follow a preventive maintenance routine: periodically diagnosing and, if needed, replacing spark plugs during service intervals, rather than waiting for the warning indicator to turn on.

Taking precautions can reduce the risk of misfires or carbon fouling, thereby maintaining peak fuel efficiency and helping the car continue to meet all the emissions standards.