We take a look at automative propshafts with GKN Automotive and how they can provide a number of advantages for workshops.

GKN Automotive propshafts offer several advantages to workshops: All parts are of the highest OEM quality and available from specialist stores and all major parts suppliers. What’s more, customers also profit from the company’s unrivalled portfolio range. GKN Automotive provides all the necessary components, from partial shafts to complete power trains.

Regardless of whether it’s a passenger car, SUV or light commercial vehicle – when replacing propshafts, quality is everything. These parts are genuine high-tech components, requiring high-precision production systems and comprehensive expertise. Workshops operating in this segment are therefore advised to order spare parts from GKN Automotive, as they precisely match the propshafts supplied to OEMs. As a leading producer of original equipment shafts, the company works closely with a large number of important manufacturers to ensure the highest quality.

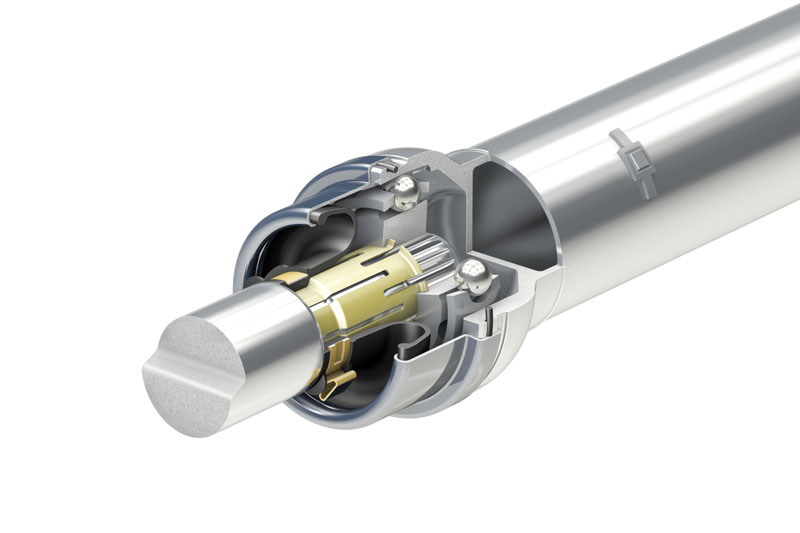

High tech for power transmission

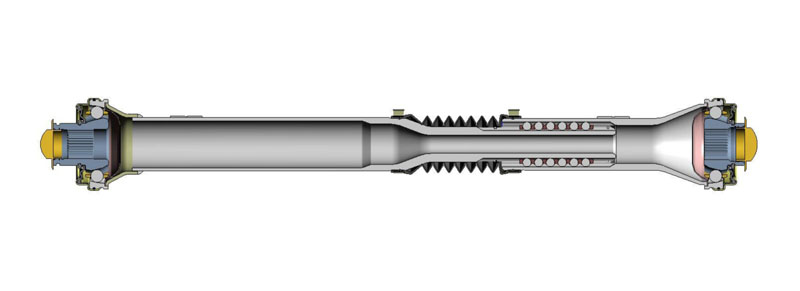

Propshafts are one of the high-tech components in modern vehicles, especially those with four-wheel drive. The new generation is no longer comparable to the “good old cardan shaft”. For instance, propshafts are nowadays an important element when it comes to vehicle safety. In the event of a crash, simply constructed joint shafts can corrupt the interior of the vehicle – with potentially serious consequences for its occupants. GKN Automotive propshafts meet the manufacturers’ high safety standards – with the best state-of-the-art technology needed in worst case scenarios.

Another important aspect in terms of driving comfort is the vibration characteristics of the shafts. In extensive test runs, GKN Automotive precisely matches the specific requirements of the individual vehicle types and their “NVH behaviour” (noise, vibration, harshness) in order to avoid annoying noises and vibrations. This process requires the selection of suitable high-quality materials as well as weight optimisation and precision balancing of the propshaft. In short, replacement shafts from are manufactured precisely according to OEM specifications, which means that the end customer enjoys the same driving comfort as in a new vehicle.

“As one of the world’s leading OEMs for propshafts, we work with the manufacturers’ engineering departments on the development of new vehicles. This enables us to offer automotive companies products tailored to the specific requirements of the individual vehicle types and manufactured precisely according to the factory specifications,” says Holger Freese, Sales Manager at GKN Automotive Aftermarket Business.

“Our workshop customers also benefit from this technology, because our propshafts for the spare parts market deliver exactly the same performance as the original parts.”

The growing number of SUVs and other vehicles with 4×4 drives, which often have multi-part configurations for propshafts, means that demand for technically advanced spare parts solutions for workshops is continuously increasing. With a broad portfolio of OEM quality complete propshafts for the independent spare parts market, GKN Automotive offers this growth segment exactly what it needs.