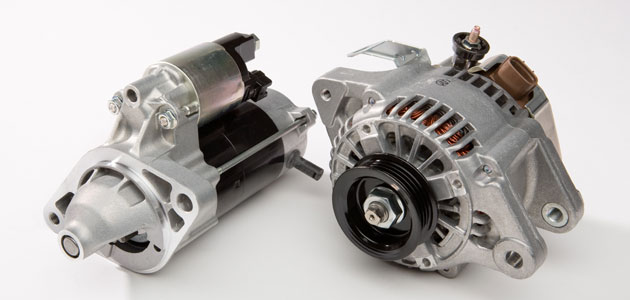

Starters and Alternators have a vital role to play – from starting the motor to keeping the vehicle running – no vehicle is complete without them.

Nick Thomas, Product Manager at DENSO Aftermarket Sales UK & Ireland explains how the company’s Starters and Alternators have evolved to bring cutting-edge, world class rotating machine technology to the aftermarket.

The second part of this mini-series looks at the history of alternators. To read part one, focussing on starter motors, please click here.

Advanced Alternators from DENSO – then and now

Leading the way with its advanced technology, DENSO’s Alternators have been part of vehicle OE manufacturing since the early 1960s. Over the last 50 years, vehicle demands and add-on technologies have developed greatly, putting more strain on the vehicle’s electronic system than ever before. Because of this, alternators have needed to develop in parallel; meeting the demand for additional electrical output by producing more power via smaller size and lighter weight.

For the last few decades, DENSO has been at the cutting edge of alternator design, with the world’s first SC (Segment Conductor) Alternator. DENSO was the first manufacturer in the world to use a rectangular conductor for its stator cell. Added to this the raising of the winding density (space factor) from 45 to 70%, enabled DENSO to develop an alternator that is 20% lighter, as well as benefiting from increased output of over 50% higher than conventional types.

In 2012 DENSO launched the first replacement DENSO Alternator for BMW, suitable for BMW 1 and 3 series. The same year DENSO Corporation celebrated the production of its 100 millionth SC Alternator.

DENSO Alternators development history

1960s – Alternator with Separate Regulator

- First alternator using a silicon rectifier

- Separate contact regulator

1970s – Alternator with Integrated Regulator

- Produced higher output using a cold forged rotor core to improve magnetic circuit

- Reduced size and weight by using an internal regulator IC

1980s – Alternator with Internal Fan

- Increased output by optimising stator and rotor sizes to improve the magnetic circuit and decreasing the pulley diameter for a faster rotor

- Fan having two fan blades, integrated with the rotor – reduced fan noise, size and weight

2000s – SC Alternator

- Using the world’s first rectangular conductor in stator coil increased winding density, reduced weight and increased output

- One chip IC regulator

The DENSO difference

DENSO Starters and Alternators have been getting our vehicles going and keeping them moving since 1961. As the world’s leading automotive components supplier, DENSO is a global leader in developing and manufacturing original equipment rotating machines. DENSO’s aftermarket Starter and Alternators programmes are subject to continual expansion, helping the company to offer a number of unique OE references. The programme currently comprises 294 part references for 2,721 key applications including OE coverage of Toyota, plus a wide range of European marques such as Ford, Audi, Opel, BMW, Fiat, Volvo and Land Rover.

Every machine is completely new in box rather than re-manufactured. With no core surcharge administration is greatly reduced; ensuring a high quality product made from genuine parts at a competitive price.