Denso is fighting against the counterfeiters by raising awareness of the issue and alerting garage owners about what they need to look out for to distinguish fake parts from genuine.

Counterfeit products are a problem in many industries, but when they are fitted to a car, the dangers they pose can be amplified, particularly when it comes to driver comfort features, such as the air conditioning system

Due to the central role that the air conditioning compressor plays, it is often described as the heart of the A/C system, which means it must operate correctly, and if it needs to be replaced, only a like-for-like unit is acceptable. However, how do technicians fitting a Denso compressor know that the part really is genuine, and not a counterfeit product, that will naturally not perform to the company’s high standards?

Responding to this important question, Denso is highlighting several of the features that technicians need to be aware of to ensure they are fitting a genuine replacement, which therefore is able to cope with the demands that will be made on it.

Using real world examples, the company stresses that although counterfeits might be supplied in traditional Denso blue boxes, that is where most of the similarities to the genuine products ended!

What to look out for

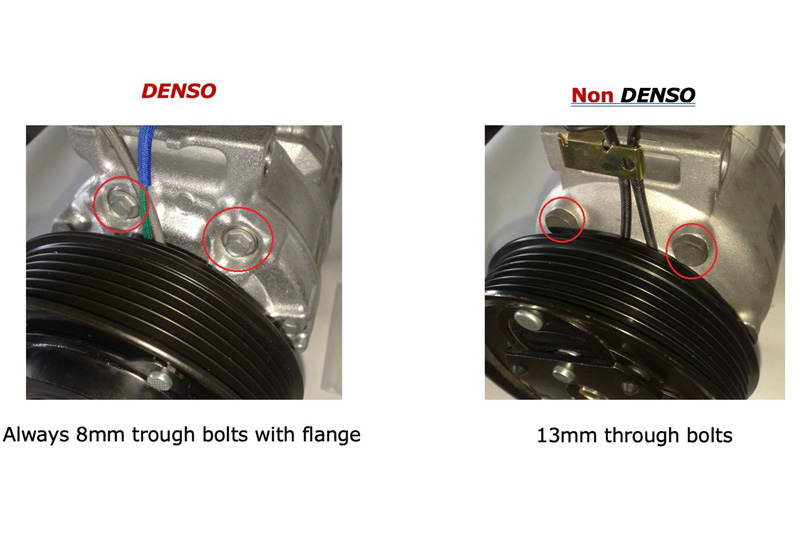

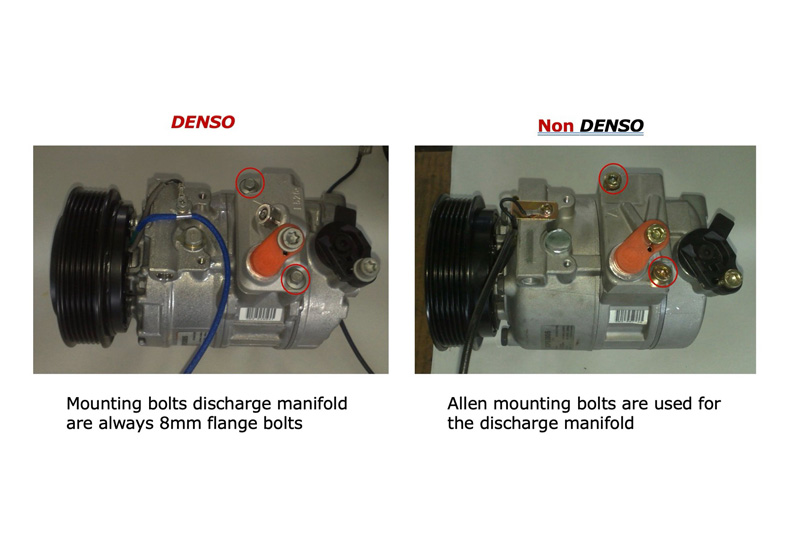

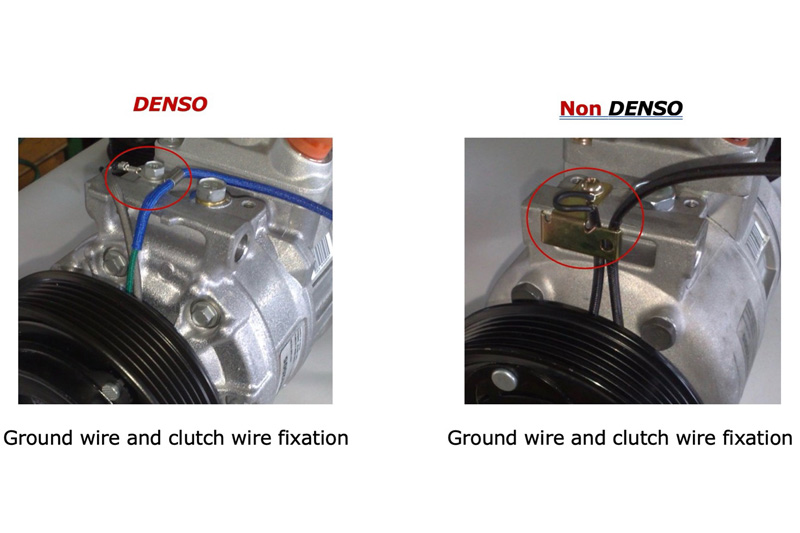

As one of the leading original equipment manufacturers, supplying vehicle assemblers globally, Denso’s products are naturally well engineered, but are also uniform in their fixings, for example. So, one of the most obvious signs that the component could be counterfeit, is a lack of consistency when it comes to the fixings used on the unit.

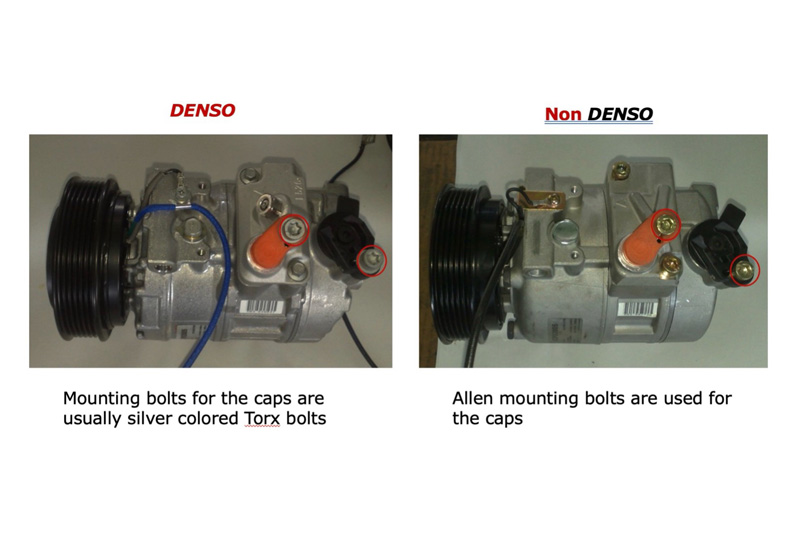

Using one example to make the case, the main image and fig 2 show how the genuine Denso compressor relies upon 8mm hexagonal flanged bolts for its assembly, whereas the counterfeit product uses a variety of different fixings – hexagonal and Allen bolts, neither with flanges. Furthermore, Denso compressors also usually use Torx bolts for securing the inlet and outlet caps used to protect the ports prefitment, but the counterfeit product here uses Allen bolts, as shown in Fig.3.

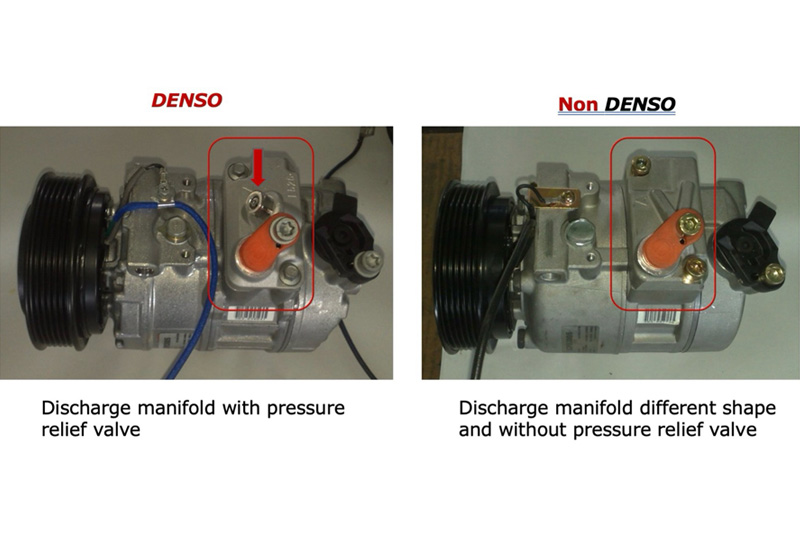

Safety issues also come to light with further examination, as the Denso unit is fitted with a pressure relief valve in the discharge manifold, a feature completely missing from the counterfeit unit (Fig.4).

In addition, the ground and clutch wires on the genuine compressor are secured using another hexagonal bolt, whereas the counterfeit version continues its inconsistent use of fixings with a cross headed screw (Fig.5).

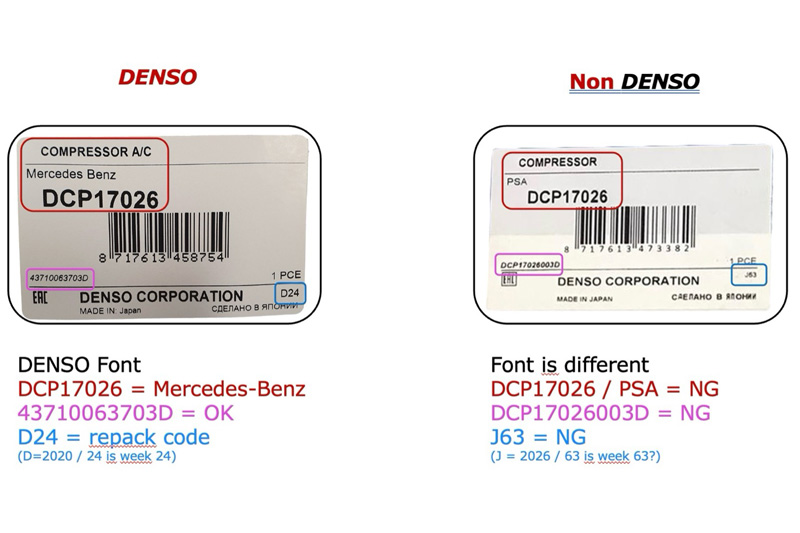

Check the labels

Labelling is another area that provides clues to the unit’s authenticity, an area that came under particular scrutiny with another counterfeit unit. Things to look out for are the consistency of design, font size and appearance etc. – does the labelling match the layout and style of other Denso products? Also, check the application because in the example shown in Fig.6, part number DCP17026 is for Mercedes Benz, which is printed on the label on the box, whereas the counterfeit stated PSA, for the same part number. In addition, is the packing code (highlighted in blue) feasible?

Further inconsistencies appear on the label on the unit, again with the font used for the part number, but of particular importance, the required oil quantity is missing from the counterfeit unit.

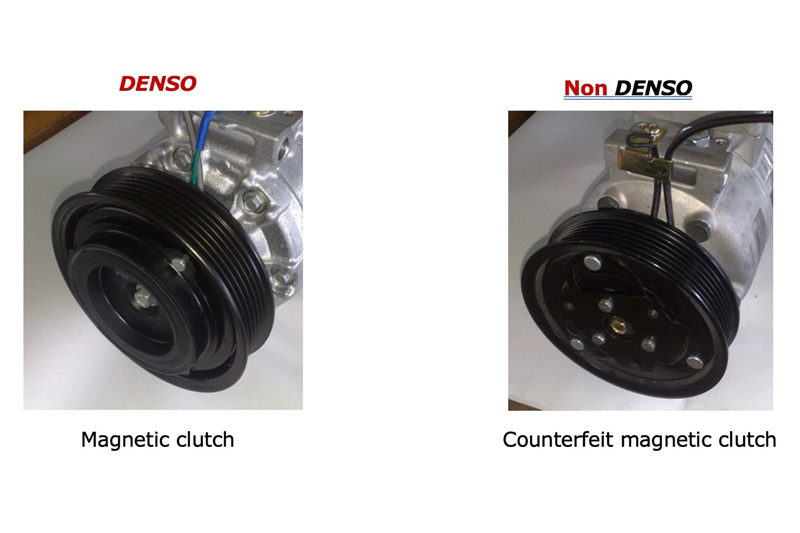

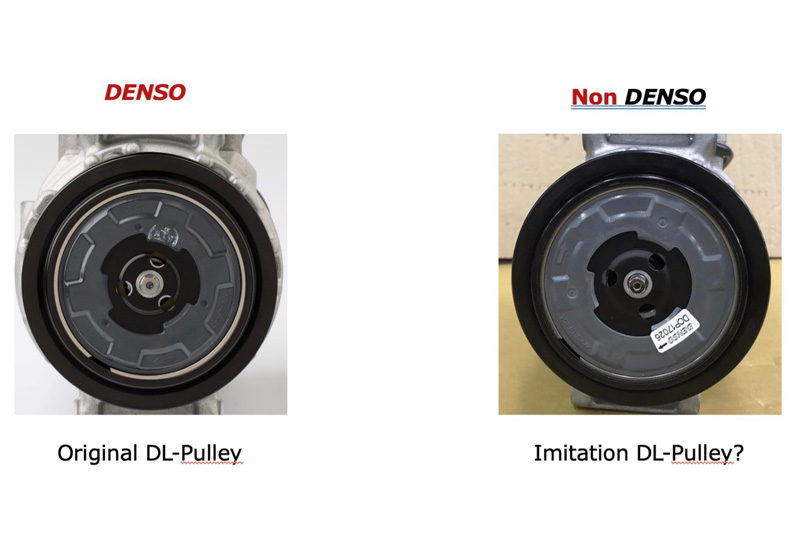

Compare the units

Unfortunately, as workshops are often under pressure from their customers to complete work as quickly as possible, these telltale signs can be missed and sometimes only come to light when the unit fails and an unsuccessful warranty claim is made.

So, the message from Denso when replacing one of its components is for technicians to take just a few minutes to look over the unit and compare it with the original, before beginning the installation. As has been highlighted, and is again demonstrated by these final comparisons in Figs.7&8, some things will be obvious, but others less so.

In summary, time spent checking before installation is worthwhile as it could save time, aggravation and money later!