Carwood reassures readers of PMM about the quality control that goes into its ‘as good as new’ remanufacturing process.

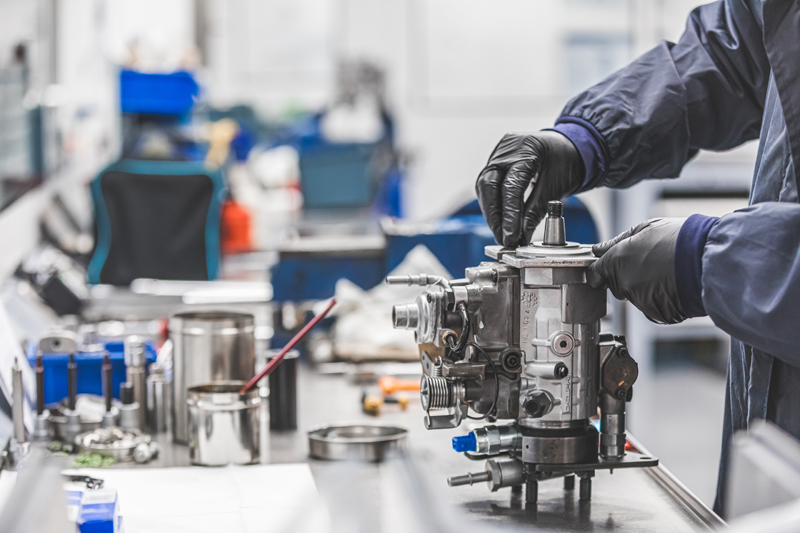

Order a reman part, and chances are you’ll hear the phrase it’s ‘as good as new’. It’s a common term in the world of remanufacturing. But saying it, and proving it, are two very different things. To consistently deliver as good as new products demands engineering excellence, quality control, bordering on obsessive, and an OEM-driven mindset, at all times. Leading re-manufacturer Carwood, believes it has these in buckets.

“Whether it’s a fuel pump, injector or turbocharger for the aftermarket, or a hydraulic pump, engine or starter motor for our wider customer base, we say we’re as good as new, because we are,” says Simon Quantrell, deputy managing director, Carwood. “It’s not a phrase we use flippantly, nor do we want to appear arrogant. For us, it’s very simple – it’s a measurable standard on which we base everything we do, and we have the quality controls in place to back it up.”

To achieve this ‘as good as new’ standard, every step of Carwood’s remanufacturing process is designed to restore the component back to the original spec, or better. Indeed, the process has been likened to the production of the original part as far as the complexity, the intensity, and the investment we have made in each stage – the difference being that Carwood restores a used part to the original spec, instead of producing a brand new one. This starts with:

Core is core: Because, like many things, you get out what you put in, Carwood’s commitment to quality control starts with core. Every used part it receives is inspected against core acceptance criteria to determine its suitability for remanufacturing. Only good core is used. Those that pass this test, the first of many, are individually sorted, labelled, and stored in a dedicated core warehouse.

Disassembly: Once selected, the unit is stripped down – each component part is individually inspected with only suitable housings and non-wearing machined parts making it through to the next stage. Any products with cracks, scrapes, faulty connectors, missing components, heavy corrosion etc are rejected and the material recycled.

Multi-stage cleaning: From there, all reusable parts are put through a rigorous cleaning process to remove any unwanted particles and contaminants – this includes ultrasonic cleaning, low VOC or water (low energy process) and surface conditioning with pressurised application specific media.

Measured to OE tolerances: After cleaning, the individual components are inspected to ensure they are within OE specification. This includes a full surface visual inspection, crack detection and measurement of the critical dimensions and tolerances with calibrated tools.

OE-grade part replacement: As an OE approved re-manufacturer, Carwood technicians replace all out-of-spec and wearprone components with like-for-like OE. For example, over 95 per cent of its remanufactured turbos are fitted with a brand new CHRA. Others have new journal and thrust bearings, piston, retaining and O-rings, and shaft nuts, replaced as standard.

For common rail injectors, it replaces 100 per cent of the ball seats, capnuts and nozzles, alongside O-rings, seals and washers with OE or OE-approved components. Other critical parts like the solenoid are replaced with new OE, or tested and re-energised, and the control valve airgap is dynamically reset using its own proprietary glitch technology.

Engineering innovation: Sometimes, if there’s a known issue or a legacy part is no longer available, Carwood will completely re-engineer the part, even if the original drawings are no longer available. Either way, the redesigned part will be as good as, or better than new.

Built to OE-spec: Carwood’s factory-trained technicians then start the process of putting the units back together again, following OEapproved build specifications and processes. Given the super-fine tolerances in common rail, its fuel pumps and injectors are assembled in an ISO certified, Class-7 clean room, capable of filtering down to 0.5 microns.

Validated by data: Finally, all Carwood reman products are end-of-line tested using the very latest test equipment and test plans, to confirm that the product has met it’s selfimposed, as good as new standards. In the case of common rail injectors, a new calibration code or trim code is generated to improve the precision and timing of the injected fuel for optimum engine, fuel consumption and emissions performance.

Full traceability: Backing up the end-to-end quality control systems that Carwood has in place, each part comes with a unique serial number for quality, warranty and audit tracking.

Industry certified: The company is also ISO 9001:2015, quality management, and ISO 14001:2015, environmental management, certified, demonstrating its unwavering commitment to meet, and even exceed, both customer, and regulatory requirements. And by virtue of being an approved re-manufacturer and supplier, its processes and output are regularly audited by the leading OE, vehicle and engine manufacturers. One could argue that this is the biggest enforcement of all.

So when you fit a Carwood reman part, you can do so knowing you’re getting proven OE performance, built on rigorous end-to-end quality control systems, validated by leading industry players, and backed by a warranty to match. That’s why the company lives by its ‘as good as new’ claim.