Battery maintenance is a process that remains very much reactive rather than proactive within the automotive industry. To convince technicians that this is the incorrect approach, Rotronics has looked into how both consumer and workshop behaviour affects how and when batteries are charged, and the resultant impact and opportunities that exist.

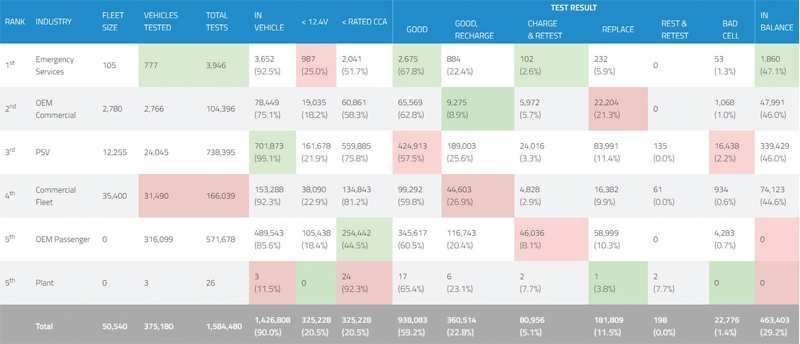

The snap-shot data in Fig 1 has been collated across several different workshop segments, whereby batteries have been tested as part of interim or planned maintenance at the point of entering the workshop over a three-year period.

The data highlights that of the 1.5m test results taken from all industry segments, 41% (646,397) of batteries require attention, with 22.8% of these requiring charging alone. Based on this analysis, this equates to around one in five of all vehicles entering a workshop having a battery that requires charging, and that one in 10 has a battery that requires replacement.

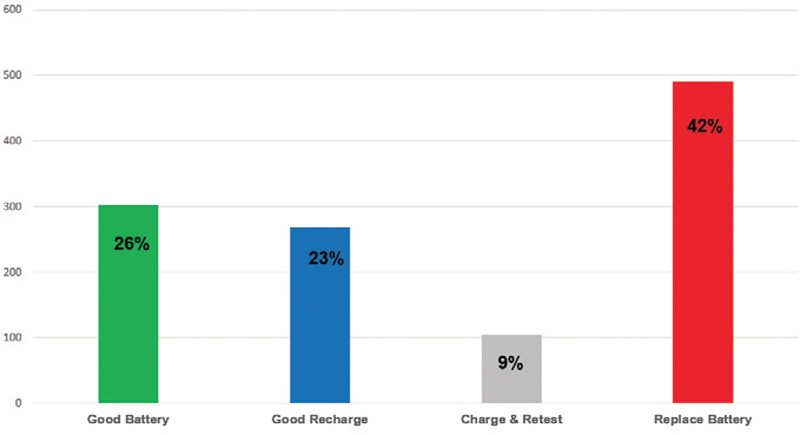

In a similar vein, an independent survey of tests carried out by a major automotive garage network over a three-month period (Fig 2), showed that of the 1,100 sample tests recorded, 74% of batteries tested required attention. Furthermore, 23% simply required charging to bring them back to a healthy serviceable state. In addition, the survey showed that there was a replacement opportunity of over 40%.

What does the data tell us?

- It doesn’t matter how efficient the vehicle’s charging system is or the type of vehicle, batteries require additional maintenance charging if they are to perform efficiently and prevent risk of vehicle breakdown

- On average, over 40% of vehicles on the road have batteries requiring maintenance or replacement

- There is a significant opportunity to offer consumer charging services as part of routine maintenance, that not only protects warranty, increases customer satisfaction and extends the serviceable life of batteries, but can generate additional revenue by offering a battery charging service.

Industry perception

Based on the research that Rotronics has carried out on the state of battery management in the automotive industry, the company has landed on the following conclusions:

■ Both workshop technicians and consumers have little understanding that vehicle batteries require charging to keep them healthy

■ The assumption is that a battery either works or it doesn’t

■ There is a belief that a vehicle’s charging system will fully maintain and charge the battery from flat, and simply keep the engine running for a period of time

■ Some believe charging a battery takes too long, and is dangerous, and needs to be carried out in well-ventilated areas with the battery disconnected form the vehicle

■ Workshops are under the impression that battery charging is not cost effective

■ Many workshops possess a charger of some form, but often use them only when they are either carrying out diagnostic work, or if a vehicle fails to start.

To support independent workshops drive a more cohesive and proactive approach to battery sales and maintenance opportunities, Rotronics has developed a management portal named ROBIS. Linking this with Midtronics’ CPX900 battery diagnostic testing platform, the comprehensive management reporting system provides instant visibility of how proactive testing can increase battery sales and customer satisfaction.

Linking this to regional and national statistics, workshops can compare how their performance measures up against the industry, and more importantly, ensure all staff are on-board with the programme.