To reduce harmful exhaust emissions, engines must become more efficient. A big part of efficiency is dependent on the quality of the moving parts used in the engine, says FAI Auto Parts. But to produce consistently high quality parts, the conditions in the factory need to be perfect.

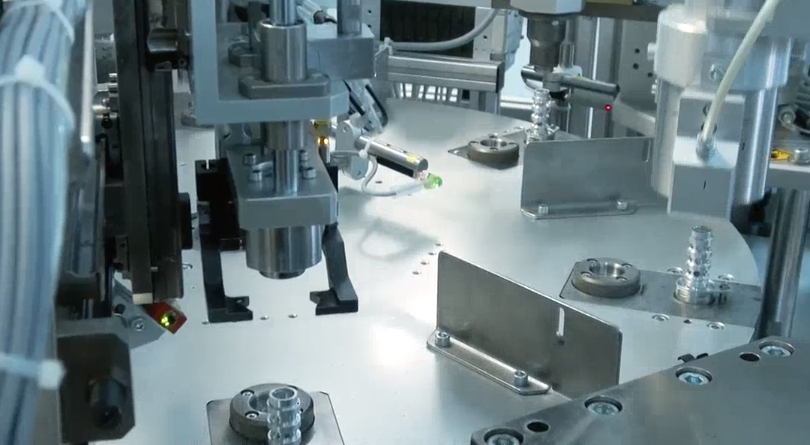

According to FAI, the only way to produce consistently high quality products with finite tolerances is by investing in state of the art production lines using the latest generation of Computer Numerical Control (CNC) machines, along with fully automated assembly lines operating in a clean environment to eliminate airborne particles. These assembly lines appear to be more like operating theatres because they are pristinely clean and must be entered via an airlock.

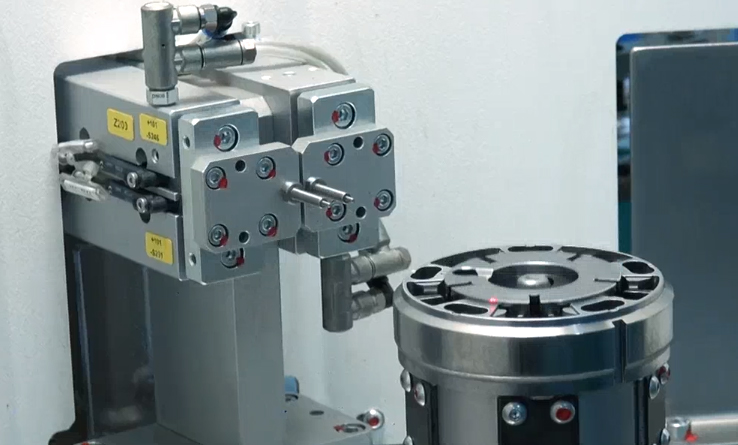

Figs 1 and 2 show an FAI production line featuring German production technology and machinery, assembling Variable Valve Timing Hubs (VVT) and Oil Control Valves (OCV). These brand-new lines ensure that the VVTs and OCVs are assembled in a pre-set sequential manner, which is automatically checked at every stage to ensure QA levels are consistent.

This means that the installer can have full confidence in the product, as any item that fails at any point in the assembly process is scrapped and not re-worked. In addition, every VVT and OCV is tested by the factory – only when it passes is it laser marked and released to the packing department. VVT hubs and the OCVs that control them are the preferred choice of engine designers, as the VVT allows the engine to operate efficiently through all power ranges. Because OEMs do not include timing chains in their service programmes, they are never inspected, and garages are therefore seeing more and more engine repairs that require the VVT and OCV replacing, as well as the timing chain and relevant parts.

A contributing factor is the proliferation of extended service intervals, which means oils are in use for three or four times as long compared to that of older vehicles, which would be changed at 6,000 miles. This intervention reduction means the oils are not inspected or replaced, increasing the chance of contamination and what starts off as a small problem can become a serious issue because a technician has not been able to look at the engine for 18,000 miles or more. FAI has factory partners that are predominantly manufacturing engine parts for OEM at tier 1 level.

This means the parts from these factories that FAI supplies into the aftermarket are made using the same materials and production processes as the parts used on the OEM production line. In today’s market where cost is always a crucial factor, FAI has the utmost confidence in its production facilities and product quality.