Vehicle designers (and drivers) wantsmaller engines for loweremissions and improved fueleconomy, yet with more power andtorque – and all with complete reliability.

That’s why Honeywell is investing heavily in R&D and constantly exploring new ideas and technologies in the search for ever greater efficiency. Their latest product builds on the principle of variable internal geometry and its highly successful VNT™ technology, to create the Honeywell VNT™ DualBoost™ turbo.

Two turbos in one

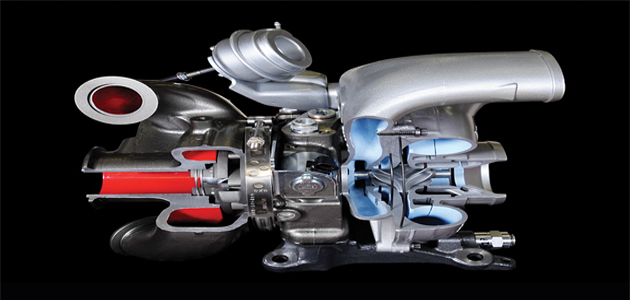

Alongside all of the advanced features on this turbo, the most revolutionary component is the dual-sided compressor wheel. The benefits of having two compressor wheels feeding an engine are well known, and two stage turbo installations are becoming more and more commonplace. However, the space available to fit them is often restricted, so the VNT DualBoost turbo combines the airflow from two compressor wheels within a single turbo.

Compact package

Honeywell accomplishes this by combining the two compressor wheels into a single piece with mirror image blades. They run in a complex compressor housing that has two separate compressor inlets and a single, common outlet. Both inlet sections also incorporate ported shrouds, to broaden the operating flow range of the compressor.

The first application of this compact package is the 2011 model year Ford Powerstroke 6.7 litre diesel V8, where the DualBoost turbo sits in the vee between the cylinders. To make installation and servicing easier, it has quick connectors for oil and coolant. DualBoost units for the smaller engines typically used in Europe and Asia will undoubtedly follow.

How does this turbo work?

It combines the vane cartridge concept (similar to that used on Honeywell’s latest third generation VNT turbos) with the variable vane assembly from their VNT DutyDrive™ (Advanced VNT), which has proved so reliable in US applications. The vane cartridge is separate from the turbine housing, for improved reliability and performance. Meanwhile in the turbine housing, a single wastegate valve allows the use of an even smaller turbine, improving response at low engine speed and enhancing turbine flow.

Reducing emissions

To cope with the latest US and EU emission regulations, the Ford engine runs very high levels of EGR (Exhaust Gas Recirculation).The variable vanes can be moved towards the closed position on demand, increasing the back pressure in the exhaust manifold and forcing the inert exhaust gas back towards the lower pressure in the air inlet manifold, to help reduce regulated emissions. This is only possible using a VNT turbo with a very powerful actuator for the variable vanes.

The DualBoost turbo uses an electro hydraulic actuator – different to that normally used on passenger car turbos. The actuator is integrated into the centre housing and uses engine oil acting on a piston to move the vanes through an internal rack and pinion gear. The flow of oil to the actuator is controlled by a variable solenoid valve, which receives its demand signals directly from the vehicle ECU via a single electrical connector.

Advanced ball bearing system

To make sure torque from the turbine wheel is transmitted to the compressor with minimal power losses, the turbo uses an advanced ball bearing system. Light weight, low inertia and highly durable ceramic balls at both ends of the cartridge combine the functions of journal bearing and thrust bearing systems, in a single compact assembly.

The ball bearing system is the result of many years’ experience gained in Honeywell’s highly successful ball bearing race/rally/performance turbo range, frequently proven by many World Rally and Le Mans series winners!

Finally, to ensure the oil, air and exhaust gas stay where they should, the turbo uses two piston rings at both the turbine and compressor ends, with the latter pressurised by air. This is fed directly from the compressor’s diffuser section, to ensure efficient sealing under all running conditions.

The shape of things to come?

The Honeywell VNT DualBoost turbo combines some of the most sophisticated turbo technologies in a single package to reduce emissions and fuel consumption while providing more power to the engine. Expect to see it closer to home soon!