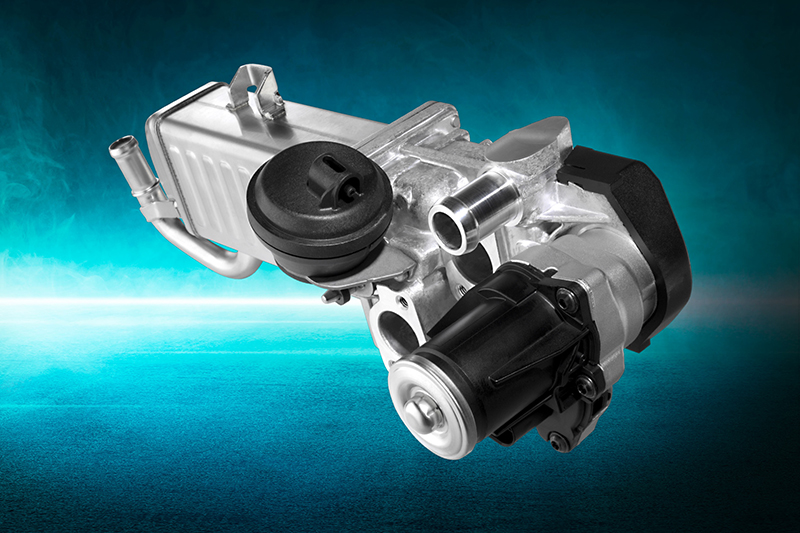

BorgWarner has outlined typical Exhaust Gas Recirculation (EGR) system failures in a bid to ensure reliability and performance in the aftermarket.

EGR systems play a vital role in reducing nitrogen oxide (NOx) emissions and improving fuel efficiency in modern combustion engines. However, like any complex engine component, EGR modules are subject to wear and failure over time. Understanding the most common failure modes such as vibration-induced fatigue, fouling, and thermal fatigue, is essential for ensuring long-term reliability and performance.

Vibration-Induced Failures

One of the most frequent causes of EGR system failure is mechanical fatigue due to vibration. EGR modules are typically mounted directly to the engine’s cylinder block, and in some cases, also to the depollution system. This positioning exposes the module to significant mechanical loads generated by engine vibrations.

These vibrations can lead to fatigue failures, particularly when the natural frequencies (eigenmodes) of the EGR module or surrounding components are excited. Additionally, relative movement between the mounting points—caused by engine dynamics—can introduce stress concentrations that accelerate wear. Over time, this can result in cracks, loose fittings, or complete structural failure of the EGR module.

To mitigate this risk, it is crucial to ensure that the EGR module’s fixation area is properly designed. A robust mounting strategy accounting for vibration damping and structural reinforcement can significantly extend the service life of the component.

Fouling and Contamination

Another common issue in EGR systems is fouling, which occurs when combustion residues accumulate inside the module. Exhaust gases contain a mixture of unburned fuel, sulfur, water vapor, ash, carbon particles, and oil residues. These contaminants adhere to the internal surfaces of the EGR valve and cooler, gradually reducing the effective flow area and impairing heat exchange efficiency.

The severity of fouling depends on several factors, including the engine type (diesel or gasoline), the EGR module’s position in the exhaust stream (pre- or post-catalyst), and the quality of fuel and oil used. Over time, fouling can lead to reduced EGR flow, increased emissions, and even complete blockage of the system.

To combat fouling, it is essential to select the appropriate heat exchange technology for each application. Materials and coatings which resist deposit buildup, along with optimised flow paths, can help maintain performance over the life of the engine.

Thermal Fatigue

Thermal fatigue is another critical failure mode affecting EGR systems. During normal vehicle operation, EGR components are subjected to repeated heating and cooling cycles. Hot exhaust gases cause expansion in certain parts of the module, while adjacent components in contact with coolant remain relatively cool. This temperature differential creates internal stresses which vary with driving conditions, such as acceleration, deceleration, and engine shutdown.

These thermal cycles can lead to material fatigue, warping, or cracking, especially in areas where hot and cold zones meet. The severity of thermal fatigue is influenced by driving style, route profile, and engine load.

Designing EGR modules with materials tolerating thermal expansion and incorporating flexible joints or compensators, can help absorb these stresses and prevent premature failure.