Automotive battery specialist Varta outlines the important role traditional 12V batteries continue to play as the vehicle car parc transitions towards an electric future.

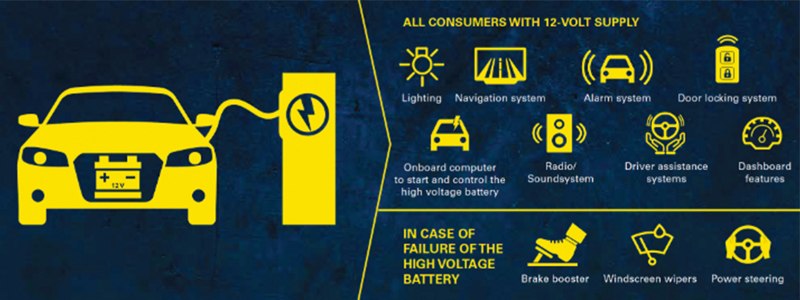

Did you know, as well as start-stop and ICE vehicles, nearly all xEVs (BEV, PHEV, FCEV, hybrids) require a 12 volt power supply? As cars become more electrified and autonomous, the traditional 12 volt lead-acid battery is taking on a new and challenging responsibility as a critical source of power across the evolving range of xEVs.

There are an increasing number of electrified vehicles entering the market to support governmental targets of reducing CO2 emissions. Their emergence has intensified low-voltage power demands and is continually redefining the role of the 12V battery. Enhanced levels of vehicle electrification have driven the 12V battery to become a safety critical component, particularly if the high voltage battery fails.

Staying safe

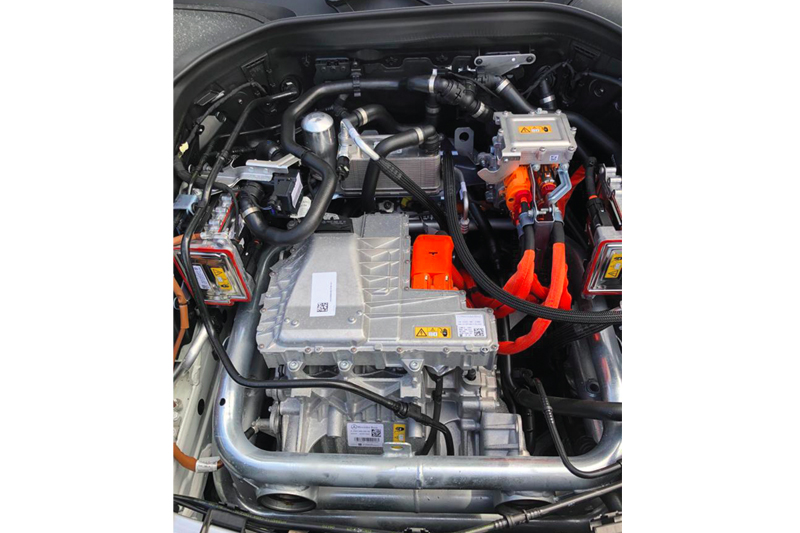

An electric car’s high-voltage li-ion battery powers the drivetrain and the propulsion system, however not the whole vehicle, and not all of its electrical power devices. The internal electrical 12V power system with its comfort and critical safety features, is powered by a 12 volt battery. It works as a secondary power source for the vehicle’s electrical system and ensures that the car maintains its functionality while driving but also whilst parked and the high-voltage battery is disconnected from the drivetrain.

Comfort and safety features like lane assist, power steering and the brake booster are handled by onboard smart systems which also draw power from the 12V system. The same goes for most of the car’s monitoring functions, it is therefore essential that a reliable 12 volt power supply is in good working order.

Why is lead-acid technology still being used in a modern electric vehicle?

Lithium-ion technology is often considered the successor of lead-acid technology when it comes to batteries. However, it is not as inherently robust as other battery technologies and requires continuous monitoring by the battery management system. Overall, it is a very sophisticated technology.

Lead-acid batteries, on the other hand, are known to be both reliable and affordable. Their wide operational temperature window intrinsically enhances the operational robustness of the entire system. The safety record of lead-acid batteries makes them invaluable for Europe’s future low-emission mobility sector, plus lifecycle analysis of a vehicle’s environmental impact show that lead-acid has a lower impact compared to other technologies.

In the workshop

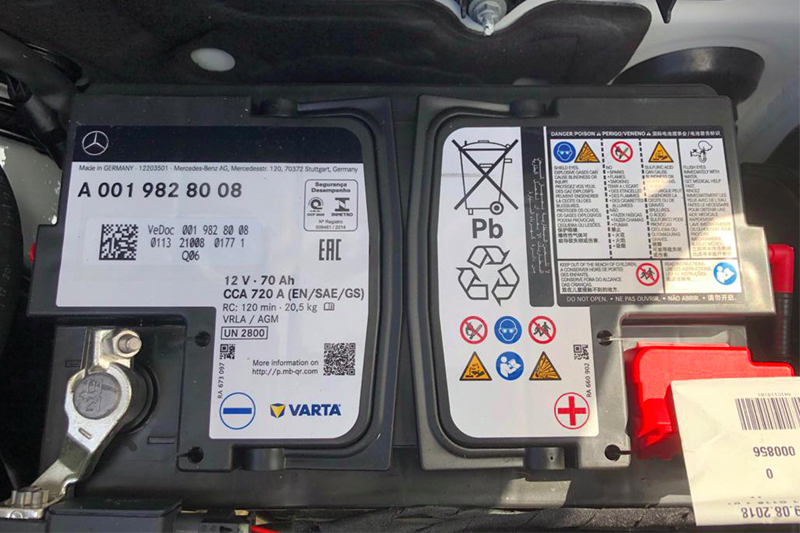

As with any 12 volt battery, there is a finite lifespan and once used, a replacement should be fitted. Varta always recommend testing the 12 volt battery of any vehicle when it enters your garage workshop, the same applies to any type of xEV.

When it comes to testing on an xEV:

- The battery cables for the high voltage battery are all orange in colour – do not touch these.

- The 12 volt battery cables are standard and the same as ICE cars in size and colours.

- The 12 volt battery testing method is the same as a standard ICE vehicle, however on full hybrid and BEV cars, the alternator and starting tests cannot be carried out as there is no starter motor or alternator fitted. Charging is completed via the inverter/converter, and starting is achieved using a motor generator in the gearbox.

- Ensure the battery tester you are using is capable of reading results from AGM (absorbent glass mat) and EFB (Enhanced flooded batteries), as well as traditional flooded batteries (sometimes referred to as SLI).

Replacement process on xEVs:

- Ensure the vehicle ignition is completely switched off.

- Remove the key and place it at least two metres away from the vehicle to prevent accidental ignition power up, of the smart entry/start system.

- Use the partner portal to identify the vehicle and the location on board of the 12 volt battery.

- Disconnect the 12v battery as per manufacturers’ instructions (there may be a high voltage ‘power-down’ waiting period).

- When the 12 volt battery is disconnected, the high voltage side of the vehicle is also powered down and cannot be powered up again until the 12 volt battery is installed.

- The installation process is the reverse of the removal, the partner portal will be able to advise if recoding of systems or components is required.

The OEMs’ choice

Varta AGM batteries have proven their reliability for many years. It is their sturdy construction, behavior and inherent safety that makes them the perfect companion in supporting the 12 volt electrical system of xEVs. The Varta 12 volt battery portfolio is engineered to support both today’s and future electric vehicles.

Being the leading expert in battery solutions, Clarios has its Varta silver dynamic AGM portfolio ready for xEV, now with added designation to the AGM labelling. Designed and tested together with leading car manufacturers, the AGM portfolio for xEV is here to prepare you for servicing the future of mobility.