UFI Filters has confirmed it is providing OE heat exchangers for Renault-Nissan-Mitsubishi Alliance’s electric motors.

UFI has been chosen to supply the heat exchanger for the new ePT-160 front electric motor, 160kW, mounted on the new Renault Megane E-Tech and Nissan Ariya. The e-motor will also equip other C-segment model vehicles that will be launched by 2024 within the Franco Japanese alliance and, according to UFI, has the potential to become very popular in Europe in the next few years.

How does it work?

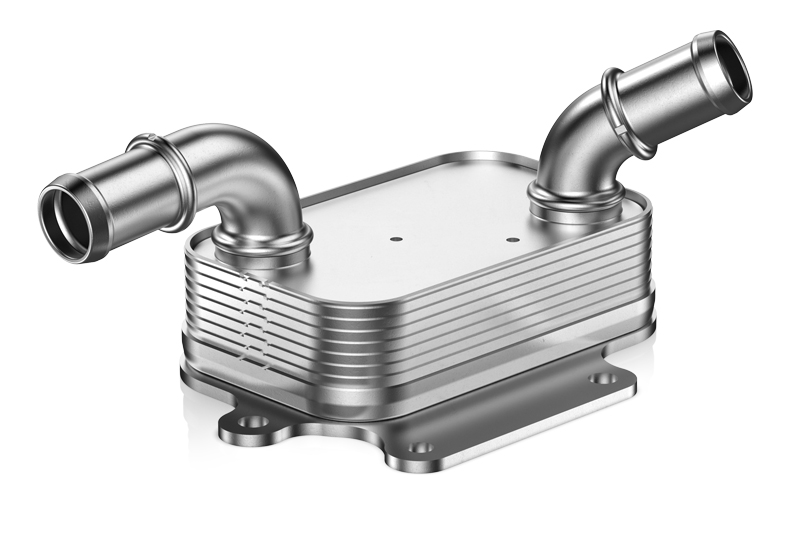

The heat exchanger for the ePT-160 is of an aluminium plate type and produced according to vacuum brazing technology that allows for a robust and clean product. The UFI heat exchanger is made up of four layers dedicated to oil and four to coolant. The oil enters through the base plate fixed directly on the outside of the electric motor. The heat exchanger configuration has diagonal counter-flows. It means that the liquids (oil and coolant) flow in opposite directions; oil and coolant cross their path into alternating layers.

For the 4×4 version available on the Nissan Ariya e-4ORCE 4WD, UFI supplies an additional heat exchanger for the rear electric motor. Also made of aluminium and featuring vacuum brazing technology, it has seven layers for oil and six for coolant. The oil and coolant liquid enter through the base plate fixed directly on the outside of the electric motor. The heat exchanger configuration has parallel counter-flows. The two liquids flow in opposite directions but remain on the same side of the plates layer. UFI Filters Group CEO, Rinaldo Facchini, said: “The collaboration with the Renault-Nissan-Mitsubishi Alliance represents a milestone for UFI Filters. It testifies that the UFI Filters Group is a technology leader in the area of electric mobility. Being present on an electric motor that goes from 120,000 pieces a year – aiming to reach 300,000 – shows that thermal management of battery-powered vehicles is one of the company’s strengths.”