Brakes

Just as electronics is revolutionising the way cars operate, it will also revolutionise the way cars are serviced and repaired. A visual check and a good working knowledge of the system is no longer enough.

Without an electronic diagnostic tool, the operation could take much longer, be less safe or even be impossible. For example, during repair there is a possibility even manually servicing the vehicle could confuse the control system, resulting in fault codes. Electric handbrake systems, for example, which have been standard on an increasing number of cars must have their electronic control units engaged while winding back the calipers so the pad position is indexed. This is essential when replacing brake pads, as the control unit needs to know the thickness of the pads in order to engage correctly.

Thermal

The refrigerant recovery/recycle and charging station should always be subjected to a complete pre-season inspection. Areas of concentration include changing the oil in the vacuum pump, calibrating the scales and gauges, inspecting all hoses for cracks and splits, checking the gauges for leaks, purging the storage tanks of air, replacing particulate and oil filters, and examining the O-rings at the service couplers for wear.

To avoid inaccurate measurements by the recovery reservoir, you should also check it for “leftover” oil from the previous season. A deep vacuum test is also highly recommended. If your unit can’t achieve a deep vacuum, you won’t be able to secure a proper charge of the refrigerant and oil following a repair. An improper refrigerant charge can lead to premature component failures, particularly with compressors.

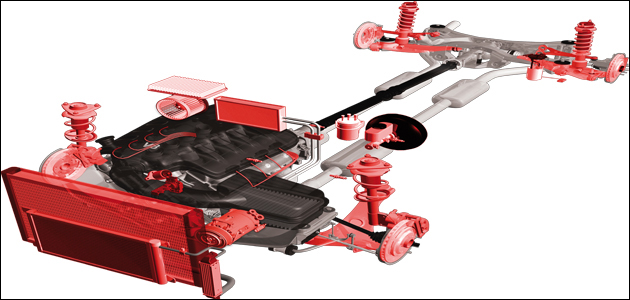

Steering

Delphi is advising technicians to help ensure a quality steering and suspension repair by replacing the entire ball joint component where the rubber boot is split, cracked, damaged or missing. In these instances, there is a high probability that damage to the ball joint may have occurred, indicating the joint is likely to fail, even after the boot cover has been replaced. Replacing the entire ball joint component can help avoid potential premature failure, which can be safety-critical and costly.

By replacing the boot only and not the complete ball joint unit, the rubber boot could potentially seal in the damaging substances the joint has been exposed to, resulting in accelerated rust and corrosive damage to the joint. In addition, the ball joint is designed to operate with a grease lubricant. A defective boot could lead to a loss of this essential lubrication, as it may be washed away with water, dry out or become coated with dirt and other debris.

Shock absorbers

Delphi is recommending that in order to ensure a quality shock absorbers repair, technicians should replace shocks in pairs versus replacing only the failed part. As part of its technicianfocused “around the wheel” communications campaign for a quality repair, Delphi’s six training courses – for beginners to advanced technicians – demonstrate the importance of diagnosis and repair for complete steering and suspension systems, including shock absorbers and braking components.

ABS

Anti-lock Braking System (ABS) speed sensors magnetically read the rotational speed of each wheel, which is fed back to the vehicle’s electronic control unit (ECU). When a wheel is starting to lock up and/or skid, the ABS system intervenes to gradually release and reapply the brake many times per second to help ensure maximum braking efficiency and directional control can be maintained.

If an ABS sensor fails, the car reverts to normal braking with no potential for ABS monitoring or modulation of pressure when a wheel, or wheels, lock up in a braking situation. Without ABS, a wheel will automatically lock up in slippery and/or gravel-like conditions, as well as potentially experiencing a loss of directional control and vehicle stability.