Winter weather can provide any number of challenges for the motorist, from icy roads to potholes to corrosion from extreme weather and salt. These can all result in possible collision damage or increased wear and tear on the vehicle. But are you ready to service these needs through the colder months? With some top winter servicing advice from Delphi, you can be.

A vehicle’s steering system can often bear the brunt of wintery conditions. Potholes, caused by extreme temperature changes, and the use of corrosive materials such as salt and grit on the road’s surface, can all accelerate component wear. For this reason we’d recommend checking key system components

for any signs of damage or wear and tear.

Lower Ball Joint

Lower Ball Joint

One such part is the lower ball joint. Given its position it is particularly vulnerable to both contamination and additional stress. Whilst ball joint replacement is not part of the routine maintenance schedule, they should be regularly inspected for damage and/or excessive movement. Other common symptoms of worn ball joints include noises coming from the vehicle’s front suspension when driving over bumps or turning and the vehicle’s steering wandering from left to right on its own. Spotany of these and the entire ball joint, not just the boot, should be replaced. Replacing only the boot will seal in any damaging substances.

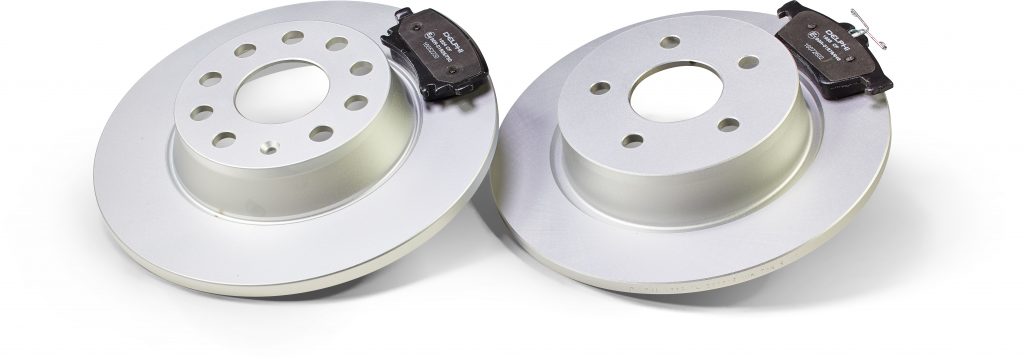

Brake Discs

When replacing a customer’s discs during the colder months, you may wish to suggest coated discs. Delphi coats the entire surface of its disc, including the top hat, outer rim, internal veins and friction surface for the ultimate corrosion protection. The special zinc-flake, geomet coating also stays in place longer, thanks to a salt spray resistance of up to 240 hours, compared with less than 100 hours for many partially painted discs. Perfect for testing winter conditions. As an added benefit, they’ll also be quicker and easier to fit since they can be fitted straight from the box with no oil to clean off.

Braking accessories are also susceptible to increased wear during winter and should be fitted as new with every job. Whilst used components may appear to be in good condition, exposure to cold weather, moisture and salt corrosion will reduce both their tension and function. Using old components can lead to unequal braking and increased wear on pads and discs.

Calipers

Similarly, dirt, salt and extreme temperatures can all take their toll on the caliper’s piston boot which is prone to cracking or hardening. If this is not dealt with, moisture can get into the caliper, causing the slider pins to rust and eventually seize. This can result in any number of problems including brake drag, brake overheat, brake fade and hot spots on the brake discs, leading to uneven wear and potentially irreparable damage to both the pads and discs. Ongoing maintenance is therefore critical and should be included as part of any routine brake service, especially when replacing the brake pads.

Air Conditioning

Contrary to popular opinion A/C servicing is not just limited to summer. An effective A/C system is essential all year round. Take the compressor for example – failure can occur anytime, and as the compressor is the heart of the A/C system, the vehicle cannot run without it. There’s also no set timing when it comes to servicing routine maintenance items. Saturated with a small volume of water, the receiver drier should be checked and changed regularly – every two to three years and each time the system is opened. Likewise the cabin filter should be replaced at least every 12 months, sooner if driving in urban conditions.

A blocked cabin filter will result in a below par heating and cooling system and cause the windows to mist up more rapidly. One winter essential is the heater core. Responsible for heating and demisting the cabin, it can fail as a result of leaks or clogs that occur if the coolant is not checked and/or changed regularly. Replacing the engine’s coolant minimizes the risk of this and provides great protection for the cold weather, saving the driver money in the long run. Technicians should also conduct a radiator pressure test, and examine the hoses for cracks or bulges.

Besides general part failures and maintenance opportunities, wintery road conditions typically result in an increase in front end crashes. In such collisions, the main heat exchangers, located at the front end of the vehicle, are often directly impacted – these parts include radiators, condensers, charge air

coolers, cabin air filter and heater cores.

Batteries

In sub-zero temperatures, a vehicle’s battery will lose voltage, or electromotive force. The increased use of car heaters and lights during the darker, colder months will also draw valuable power from the battery. Older units may struggle to start, or may not even start at all and will need to replaced. In addition, you may wish to consider a pre-winter battery testing service to check the condition under load – both represent quick and easy service wins.

Glow Plugs

The mainstay of winter servicing, glow plugs are critical in  helping vehicles start in freezing temperatures. As such they are one of main causes of starting issues during winter and represent a great service opportunity. Technicians should test their customer’s glow plugs or even replace them

helping vehicles start in freezing temperatures. As such they are one of main causes of starting issues during winter and represent a great service opportunity. Technicians should test their customer’s glow plugs or even replace them

if they are a few years old – just one faulty glow plug could prevent your vehicle from starting. Even if they are still functioning, there could be problems which may lead to premature failure.