Vehicles with full-hybrid technology use high voltage compressors that are not dependent on the running of the combustion engine. This makes for greater A/C comfort in such vehicles.

A vehicle’s interior that has become overheated can now be cooled down to the desired temperature before the start of any journey by using a remote control. This stationary cooling process can only be brought about if sufficient battery capacity is available.

The compressor is controlled with the lowest possible output with the necessary A/C requirements being taken into account. In the high voltage compressors used today, the power is regulated by adjusting the rotary speed in steps of 50 min-1. It is therefore not necessary to have an internal power control.

Function and design

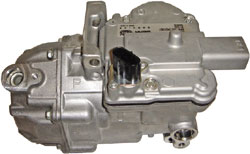

In contrast to the ‘swash plate’ principle, which is primarily used in the belt-driven compressor field, high voltage compressors use the ‘scroll’ principle to compress the refrigerant. The benefits are that the weight is reduced by approximately 20% and there is a reduction in the cylinder capacity of the same amount, whilst the output remains identical.

In order to generate the right amount of torque for the drive of the electric compressor, a DC voltage of over 200V is used.

Specialist subject You should be aware that appropriate staff training is required for the servicing of hybrid vehicles, with further skills imperative for those who service and repair the complex thermal management systems found in hybrids. In Germany, for example, those employees who work on high voltage systems are obliged to attend an additional two-day course in order to qualify as an “Electrician for High Voltage Systems”.

You should be aware that appropriate staff training is required for the servicing of hybrid vehicles, with further skills imperative for those who service and repair the complex thermal management systems found in hybrids. In Germany, for example, those employees who work on high voltage systems are obliged to attend an additional two-day course in order to qualify as an “Electrician for High Voltage Systems”.

The course teaches the technician to recognise the risks when working on systems of this kind and also how to switch off all the current to the system for the duration of the work. It is prohibited for people who have not attended specific training courses to work on high voltage systems.

Also, tasks dealing with general servicing and repairs (such as work on exhaust systems, shock absorbers, oil changes and the changing of tyres) may only be carried out by employees who have attended the same course, in order to learn about the risks associated with these types of systems.

Tools of the trade

It is also essential to use tools that comply with the specifications provided by the manufacturer of the hybrid vehicle. During the A/C check and service, steps must be taken to ensure that the electric A/C compressors ARE NOT lubricated with standard PAG oils, as these don’t have the necessary insulation properties. POE oil or a special type of PAG oil is normally used instead, as these have the required properties.

Consequently, A/C service units with an internal rinsing function and a separate fresh oil reservoir should be used for the A/C check and service in hybrid vehicles. This then ensures that any mixing of the various types of fresh oil is prevented.

The Hella Tech World Portal contains hundreds of tips and technical hints.