Creating a reference library of ‘known’ vehicle behaviour in a variety of conditions can help garages to overcome emissions problems relating to Lambda sensors, as Daniel Barker, TEXA’s Technical Manager, explains.

Looking at the calls logged through our technical helpline recently I was amazed to find that one of our most popular reports still relates to the humble (but important) Lambda sensor.

The general theme running throughout the calls we’ve received relates to the garage fitting a new Lambda sensor to the vehicle, but the car returning at a later stage with the same fault. This is a common problem, but one that can be overcome through the use of your diagnostic tool or an emissions analyser.

Reference points

Put simply, by investing some time and effort, the garage can build a quick reference diagnostic library, which can be created for a whole range of sensors (not just Lambda).

The first part of the process is to ensure you’ve got a ‘known good vehicle’ in the workshop from which you can take a recording of the sensors you know the least about. Once you’ve identified the sensor types for which you’re going to build this library, you then need to record the individual sensor’s signals under different conditions, referencing it against variables such as engine rpm and throttle position.

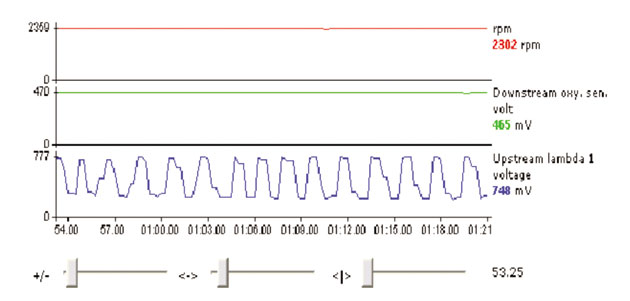

The capture below shows some samples that I’ve created as a reference point for a Lambda sensor. These took me about 15 minutes to achieve and could potentially save me hours in the workshop.

In the sample I’ve kept the engine at a constant speed of 2,400 rpm under no load and recorded both the upstream and downstream Lambda sensor. The vehicle has a known good catalytic converter on it so, in simple terms, I now have a reference point relating to a vehicle with a good catalytic converter. This can now be saved in the customer database section of our software as “Good cat readings”.

In the same way, it is also worth getting a reading of a Lambda sensor on a vehicle with a ‘bad’ catalytic converter. Even though this type of information is pre-loaded into TEXA’s own diagnostic software we still advise that you undertake this process yourself so that you can understand what to do and why you’re doing it.

Take it for a test run

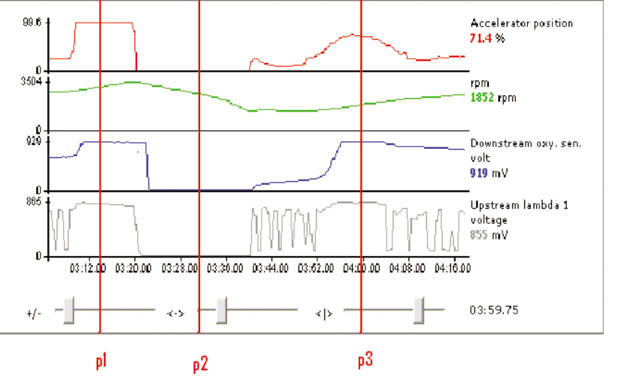

The next set of recordings that we’d recommend are not something that can be put into our software library – only you can do this! The capture below shows two recordings that were captured after taking a vehicle on a test run.

As you can see, it covers a range of driving conditions which allow you to assess the vehicle in a real-time environment and it seems crazy to me that some garages don’t use this opportunity to plug in their diagnostic tool and collect such valuable information to help with understanding the sensor’s relationship under different driving conditions.

The capture shows me driving the vehicle down the road and if you study the waveforms you can see that at point 1 I’m accelerating up to a roundabout, in point 2 I’m decelerating to the same roundabout, while at point 3 I’m accelerating onto the motorway. I therefore now have some known values of acceleration and deceleration in my library.

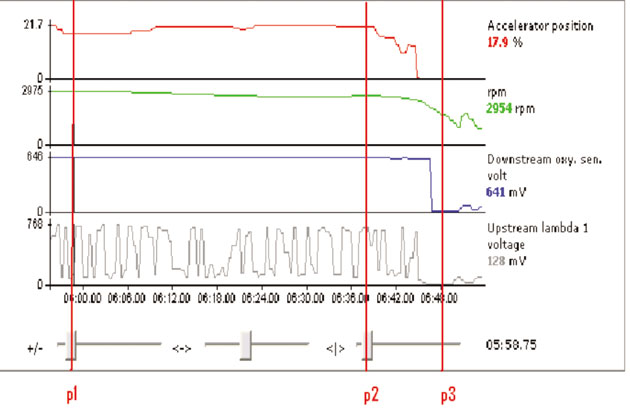

The image below shows me driving at a constant speed down the motorway (from point 1 to point 2), which provides me with a recording of normal driving. Point 3 then shows me decelerating as I come to a junction.

What value?

If you’re still wondering why it’s important to make these sorts of references, it is simple really. By having the direct relationship between you, the vehicle and the test run you use daily you have a direct example of what the vehicle may be doing at a given time. This ultimately helps you understand the relationship of the information you are viewing in the recording as you can visualise it! From a customer perspective it also means that you can take them on this run and do the recording at the same time. This is a great way of showing the customer a proof of the issues their vehicle may be suffering from and will help them to better understand why the repair work (and bill) is what it is.

From a customer perspective it also means that you can take them on this run and do the recording at the same time. This is a great way of showing the customer a proof of the issues their vehicle may be suffering from and will help them to better understand why the repair work (and bill) is what it is.

Practice makes perfect

In conclusion, it is important to recognise that purchasing a diagnostic tool is just the first part of your investment. Of course the manufacturer can put lots of features into the tool and can also train you how to use it but, essentially, the workshop still needs to make the most of the available features by spending some time and effort to create good reference points from which to work off.

The more time that you invest in doing this, the more it is likely to pay you back further down the line.