PMM ’s troubled troubleshooter Ben Johnson stumbles through numerous fault codes and takes a look at fixing a BMW N20 that staggered its way into his workshop.

It’s a rarity these days, a genuine anomaly, to have a vehicle stagger into the shop, presenting a problem more intriguing than the textbook misfire caused by a rebellious coil or an injector shedding more tears than a reality show contestant on the brink of being sent home. So when this particular vehicle was towed in, I was already convinced that a mundane misfire wouldn’t be on the day’s agenda. Such was my conviction until I perused the epic tale etched across the job card, a veritable odyssey of mishaps. After battling through the dense Finnish prose, converting into English as I went, I was left with only the remotest possibility of an easy passage home. My woes were matched only by those of the vehicle’s owner, who had, in a burst of optimism, attempted to clinch the pole position at the impromptu Vantaa Grand Prix off the traffic lights. However, whether it was the automotive gods looking down disapprovingly, or simply the quirky little habit BMWs tend to have of failing at the most inopportune moments, this driver’s quest for motoring glory was cut short with a dramatic thud and a blaze of warning lights, his trusty steed stuck to the tarmac, unable to carry on.

This was a stark reminder, a nudge from the universe, that to assume anything in the realm of fault finding is to invite chaos itself for tea. It’s as if the gremlins lurking within these headaches on wheels conspire to keep us humble, underscoring a truth known all too well in our line of work: the moment you believe you’ve seen it all is precisely when you find yourself on the threshold of yet another automotive odyssey. So, it’s time to fasten our seatbelts – figuratively speaking – as it appears the deities of fault finding have deemed it necessary to refresh our memory. In the unpredictable world of car repair, the only constant is, ironically, the sheer unpredictability of it all.

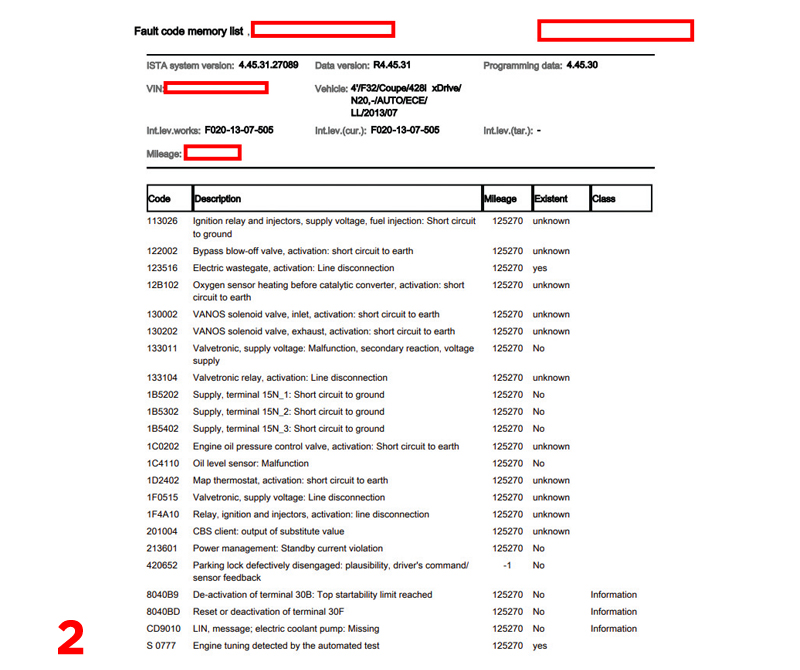

Diving into the labyrinth of fault codes is a bit like trying to decipher the Rosetta Stone with a hangover – challenging, mildly infuriating, but oddly rewarding when you start to see the patterns emerge. Among the hieroglyphics that modern cars throw at us, a few symbols – or in our case, fault codes – stand out not just for their ability to confuse but for their sheer, unadulterated clarity. Yes, amidst the chaos, there are beacons of light and for those of us who fancy ourselves as automotive Sherlock Holmes, these highlighted images are our Dr. Watsons.

Now, let’s cast aside the usual headache of trying to wrestle every single fault code to the ground and focus on the most important ones. Glancing at fault code 113026, we’re not just looking at a short to ground – oh no, we’re staring into the abyss of an electrical Armageddon, a short so bold it might as well have its own theme music. And then, as if to add insult to injury, code 1F4A10 waltzes in, casually announcing that the fuel injectors and coil packs power supplies have decided to take a sabbatical.

So here we are, left pondering the existential questions of our time: Why has our trusty set of coil packs ceased to spark? And why oh why have our fuel injectors taken an unexpected leave of absence from their daily grind of atomising fuel into the cylinders of this trusty N20? (Fig.1). We can’t help but feel a tingle of excitement – because solving this puzzle is what gets our sprockets turning (Fig.2).

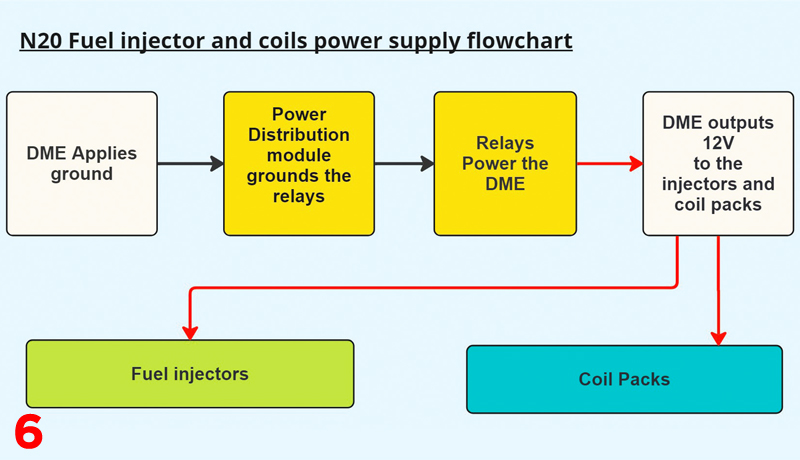

At the heart of diagnosing this puzzle is understanding the system. Essentially, the injectors and coils have been benched because of an active short. Shorts to ground are notorious for their potential to escalate from a spark to a bonfire. Sensibly, the DME has decided to cut the power to prevent any pyrotechnics. Here’s how it works: the DME grounds the relays in the power distribution module, which in turn energises the relays nestled inside. Once energised, these relays supply 12V to the fuses within the same module. This action makes voltage available to the DME, powering up our coil packs and injectors (Fig.3).

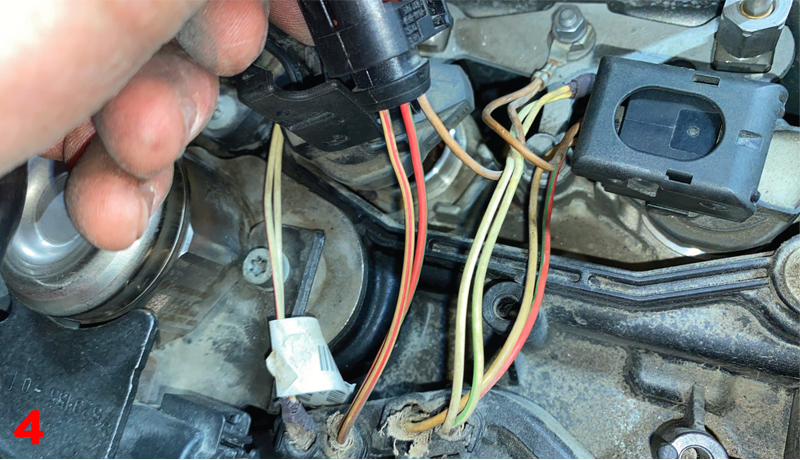

Convinced the culprit lay with a rogue injector or coil, I dove straight in, pulling the coils first. The second coil looked like it had seen better days. In a stroke of luck, leaving this coil disconnected allowed the engine to start on three cylinders. After this, I was able to clear the fault codes (Fig.4).

The source of the voltage comes from the power distribution module and sure enough it was as dead as a doornail, zero volts displayed on the red/green wires of the main connector and the trigger wire, a grey jobbie, was showing 12V – a sure sign of a ground switch not grounding (Fig.5). When we see 12V like this it should be understood that it is there as a substitute value, it is there in place of the ground to prevent the ground switching relays in the power distribution box. It may be 12V but it has no potential so to speak (Fig.6).

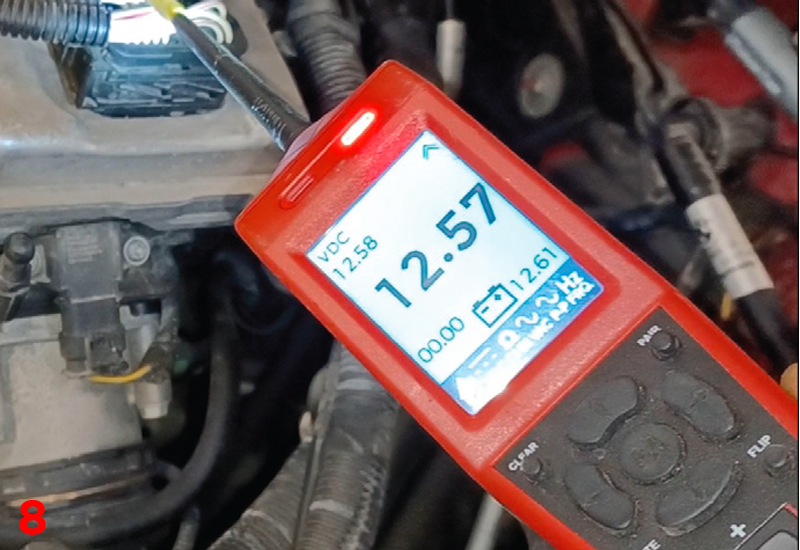

Armed with the Power Probe Maestro, the next logical step was to scrutinise the ground trigger. Upon testing, it was observed that reintroducing the number 2 coil pack caused the ground trigger from the DME to switch to 12V (Fig.7). Replacing the coil with a new one didn’t rectify the issue, leading to a detailed inspection of the coil pack wiring. Surprisingly, the ground and power supply were intact, but the switched signal wire from the DME exhibited a ground when it was expected to show around 3.7V. This anomaly pinpointed our culprit (Fig.8).

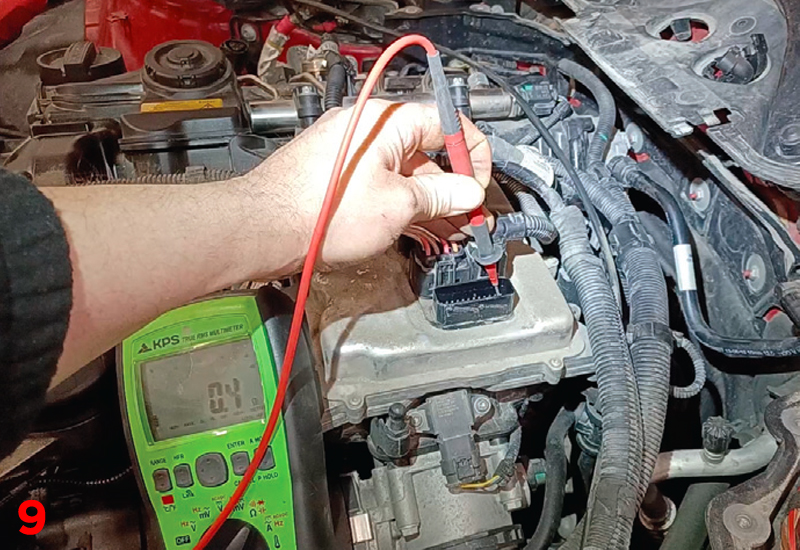

The critical question arose: was the fault due to a short in the wiring harness or a faulty DME transistor? A simple test by disconnecting the wire from the DME pin 13 allowed the car to start, suggesting a closer examination of the DME. Disconnecting the wiring and conducting a continuity check to ground on pin 13 of the DME (coil 2 signal) confirmed the diagnosis: the DME, or more precisely, its transistor, was compromised (Fig.9). The evidence suggested that the malfunction was not due to the wiring but likely caused by the problematic coil pack burning the transistor inside the DME. Usually, this fault would not prevent the car from starting but there is always a first time for everything.

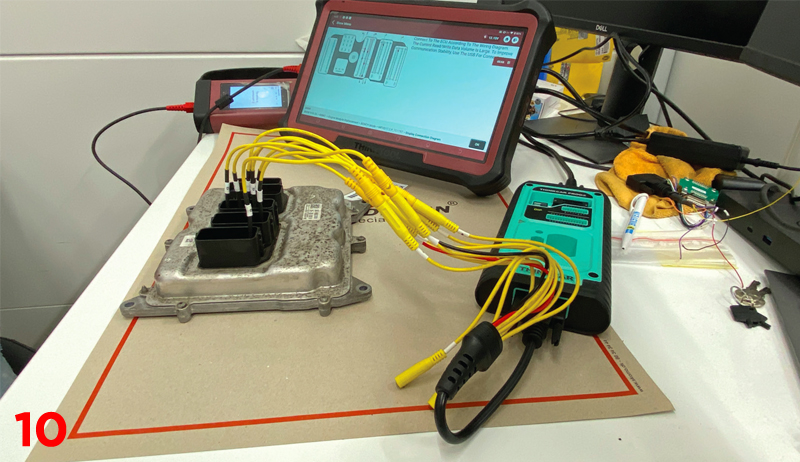

With the diagnosis clear, the decision was made to replace the defective coil and spark plug. Meanwhile, a used DME was sourced and cloned using the Thinktool Euro Master, which facilitated the cloning process to a straightforward plug-and-play operation (Fig.10). This repair strategy brought the 428i back to life, running smoothly once again.

This N20 engine is back in action, purring away without any current threats that might lead to another transistor meltdown in the number 2 coil pack. As is often the case, budget considerations guide many repair decisions. This time, the focus was solely on replacing the offending parts: the number 2 coil and, as a precaution, its spark plug. Ideally, a full set of four coils and plugs would be the recommendation for a comprehensive fix, yet the reality of customer preference and financial constraints led to a more targeted approach, addressing only the directly affected components.

The journey of automotive fault finding is as much about learning and applying knowledge as it is about the satisfaction of resolving issues. Each success builds more confidence and expertise. And remember, for more insights into fault finding and to see these principles in action, don’t forget to check out my YouTube channel for further fault finding insights. Here’s to continually expanding our horizons, applying what we’ve learned, and celebrating every victory along the way. Until next time, keep nurturing your skills and enjoy the journey.