Grease is the word

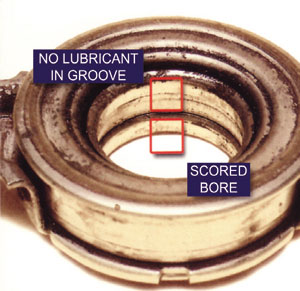

Problem: Release bearing not lubricated

Without any grease on the bearing guide tube or in the bearing recess, the bearing bore will become scored and the clutch action will be jerky, with a heavy pedal feel.

Remedy:

Enusre that the grease is applied to the bearing guide tube or the groove on a new bearing is filled with good quality, high melting point grease. If necessary, also renew the bearing guide tube.

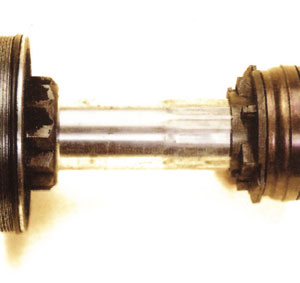

Problem: Incorrect spline grease

The wrong grease on the driven plate splines will lead to clutch drag due to dirt contamination of the splines.

Remedy:

Thoroughly clean the first motion gearbox input shaft and apply a smear of approved grease before renewing the driven plate.

Problem: Worn bearing guide tube

The incorrect lubrication on the bearing guide tube will also cause a jerky clutch action and a heavy pedal.

Remedy:

You should replace the worn guide tube and lightly lubricate it with an approved grease.

Location, location, location

Problem: Broken spring fingers

When the cover assembly is not located correctly on the flywheel or the bearing over-travels, the spring fingers are allowed to come into contact with the driven plate and will break off.

Remedy:

Ensure that the release mechanism, including the auto adjuster, is working correctly and replace the complete clutch and any other damaged parts, before re-setting it properly.

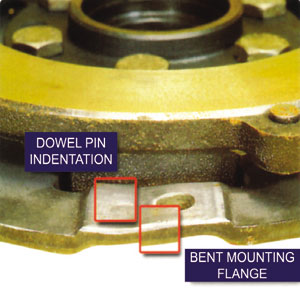

Problem: Distorted cover mounted flange

Another effect of an incorrectly located cover assembly is vibration and clutch drag.

Remedy:

Check the flywheel dowels for damage and if they are fine, correctly fit a new cover assembly.

Problem: Damaged driven plate

If the driven plate is fitted the wrong way round, the clutch could be completely inoperative and damage will result.

Remedy:

Replace the driven plate assembly and install it in the correct direction. Also check for damage and, if necessary, replace the cover assembly.

CHART TOPPERS

With clutch replacement now often taking several hours it’s imperative to workshop profitability that technicians have the information they need to fit the replacement correctly, first time.

To help them in the process, Borg & Beck has produced a useful fault diagnosis chart (pictured) to highlight the issues that can result from incorrect clutch fitment, so that fitting problems can be avoided and business profits and customer satisfaction retained.