There are a number of potential complaints that can arise when you have a secondary air system problem. These include non-starting of the secondary air pump after a cold start; the engine compartment smells charred; traces of melting on the electrical contacts of the secondary air pump and fault code P0410 “Malfunction”.

Each of these conditions indicates that the secondary air pump has failed due to overload.

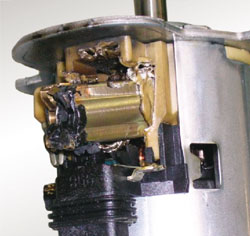

Damage: melting traces on the housing

Possible causes

The secondary air pump is not designed for continuous use and, during a cold start, the pump may only be in operation for a maximum of 90-120 seconds. In this case it appeared that the secondary air pump was energised for an impermissibly long period of time, which suggests that the relay via which the pump is controlled is likely to have been jammed.

Damage symptoms: melting traces on the electric motor or on the electrical contacts

How to check

Firstly you should identify the respective relay through the vehicle’s circuit diagram.

With cold vehicle engine

The secondary air pump has to start audibly after a cold start of the engine. If the power supply of the secondary air pump is fine, but the pump runs with a scraping, whistling or scratching noise (or not at all) the component should then be replaced; we also recommend that you replace the relay at the same time as well. In such cases, all other secondary air system components should also be checked.

With warm vehicle engine

Start the vehicle engine and check the electrical contacts of the voltage supply to the secondary air pump. The relay is jammed if the voltage is present at the secondary air pump.

In this circumstance you should replace both the relay and the secondary air pump.

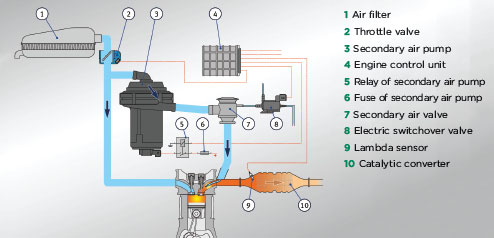

Block diagram of secondary air system (pneumatically operated)

Final check

The secondary air pump has to run for about 90–120 seconds after a cold start of the engine.

FAST FACTS: SECONDARY AIR SYSTEM

A “rich mixture” (λ<1), i.e. a mixture with excess fuel, is required for cold start of a petrol engine. Thus, large amounts of carbon monoxide and unburned hydrocarbons are produced during cold start.

To reduce the level of these pollutants, ambient air with a high oxygen content (secondary air) is injected into the exhaust manifold directly downstream of the exhaust valves during the cold start phase.

This results in post-oxidation (afterburning) of the pollutants to form carbon dioxide and water. The heat generated in this process additionally warms the catalytic converter and speeds up the start of Lambda control action.

You can find more product and servicing tips by logging on to www.ms-motor-service.com