Vehicle: VW Golf 1.9 TDI

Engine code: ALH

Year: 2001

Symptoms: Rough running on cold start–up, white smoke and smell of unburned fuel. A lack of power and general poor drivability were also noticeable.

The car came to me after the previous repairer had spent a week or so scratching their head and searching the internet – with nopositive outcome. My first action was to plug in the VAG–COM Diagnostic System (VCDS) to pull any Diagnostic Trouble Codes (DTCs). There was one:

‘17656/P1248/004680 — Start of Injection Timing Regulation: Control Deviation’

Looking at the measured value blocks (MVB) group 004, I noticed that the actual injection pump timing was too far advanced in relation to spec. With the coolant temperature at +85°C, I switched to basic settings on the TDI timing checker but it was that far advanced it would not plot on the graph. At this point I suspected the N108 commencement of injection (COI) solenoid was stuck advanced.

I selected the output tests and actuated the N108 COI control solenoid which made the engine tone change, and told me it was functioning.

I retarded the timing to a point where it started to graph and set to spec for the post–1999 ALH engine. This also cleared the DTC and made a big difference in how the car drove and pulled. I tried an engine start after it had cooled and the smoke seemed better too, but this was not exactly a cold start test. As it was, I let the previous repairer take it back to try a cold start the following morning. Sadly this wasn’t very good, and the car once again came back to us.

A check again for DTCs with the VCDS revealed no codes and the timing was still in spec.

What next?

My next train of thought was that there could be an overfuelling issue on start–up so I adjusted the injection quantity (IQ) to trim the fuelling to see if that made any difference……unfortunately not!

At this stage we knew we were looking at something else.

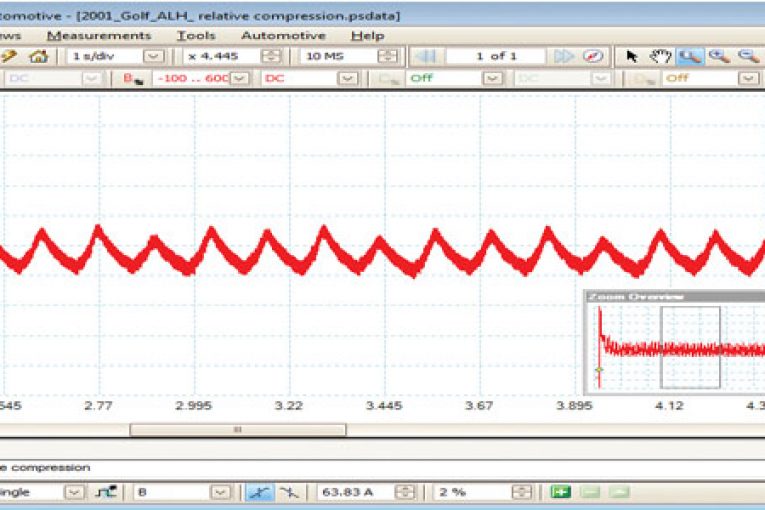

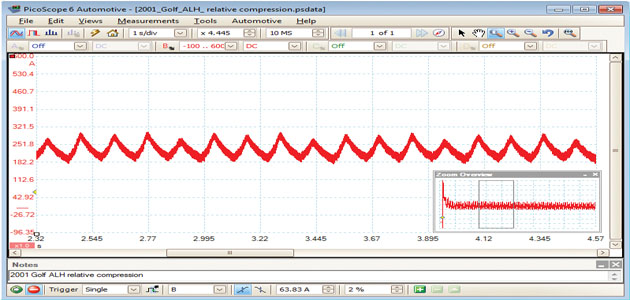

I hooked up the PicoScope with a 600A clamp around the battery cable and did a relative compression test (pictured below).

Relative compression test using PicoScope

This method is non–intrusive and takes a matter of minutes, rather than hours, removing injectors or glow plugs.

I saw what I expected to see: the smooth running correction values were high for cylinder#3, which was adding very close to the limit of 2.0 mg/stroke, indicating a weak cylinder (a negative value shows a strong cylinder).

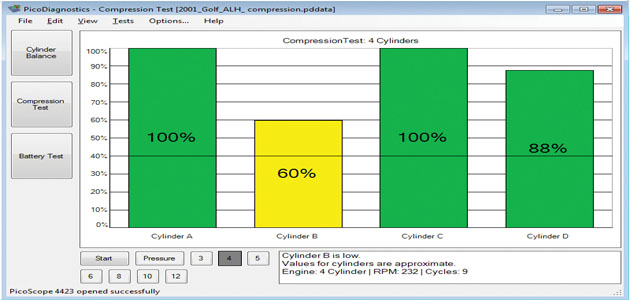

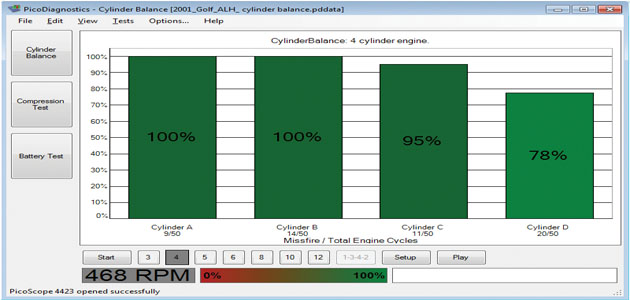

Just to back up that capture, I undertook a compression test through Pico Diagnostics (pictured below).

Relative compression test using Pico Diagnostics

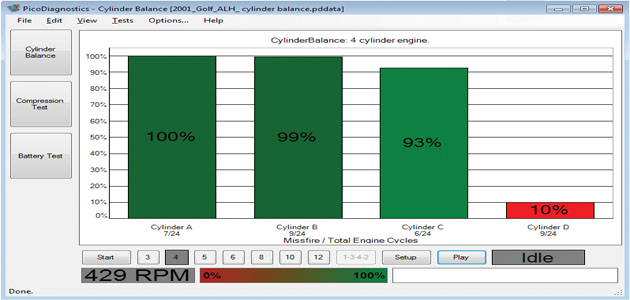

After this test I put the wire back on the N109 stop solenoid and started the car, running the cylinder balance test. This started with one cylinder in the red (Fig 3) but picked up quickly into green (Fig 4).

Fig 3

Fig 4

It was pretty obvious by now that there was a problem with the engine internals. When the car came to me the second time (after cold start) I said that, had it been a TDCi, I would have suspected a bent con–rod as this clears (to an extent) when warm.

It took five minutes to grab that information with the PicoScope in a non–intrusive manner – just another example of the information that can be pulled in such a short space of time thanks to Pico.