Wayne McCluskey, Technical Training Manager at ZF Aftermarket, offers some advice that could help to reduce unsubstantiated warranty claims on Sachs clutches.

As with any mechanical product, a certain level of warranty returns is anticipated, two of the most common reasons being that the new component is either faulty or doesn’t fit correctly. However, investigations reveal that problems can be more often attributed to fitting technique than to product quality.

What’s faulty – the component or the diagnosis?

Where fitting a replacement clutch either doesn’t cure a problem, or only appears to relieve it for a limited time, the newly-fitted item is sometimes assumed to be faulty. However, it could also indicate that a more thorough diagnosis is required to identify the root cause of the symptom.

Once the vehicle is dismantled for inspection, signs of normal wear and tear are to be expected, but abnormal wear or obvious damage indicate a fault in the system. After cleaning, detailed examinations of the clutch cover, driven plate, release mechanism and gearbox input shaft splines may offer clues as to the cause. Examples include friction linings contaminated by lubricants (see below), or that have been overheated through slipping (see below), or corrosion on the splines of the input shaft or driven plate hub, causing drag.

The crankshaft rear oil seal and gearbox input shaft seal should be checked for oil leaks, the hydraulic system examined for faults and the clutch release system assessed for wear. Cleaning the bellhousing thoroughly will also help to guard against contamination of the new clutch. If any of these areas are harbouring a problem that’s left uncorrected while the clutch is simply replaced with a new item, it’s likely that the original fault will either persist or reappear within a short time.

Obtain the correct part

Having established which parts need replacing, they need to be carefully sourced. A surprisingly high number of warranty claims are caused by fitting – or trying to fit – the wrong parts. Both the supplying motor factor and the workshop should check that the application precisely matches the vehicle’s engine code, gearbox code and Vehicle Identification Number.

Check condition of new parts

A new Sachs clutch will have been checked for conformity to strict quality standards at each stage of its manufacture, but it can sustain damage if not handled and stored correctly when in transit. In particular, the friction disc axial run-out (Fig 3) should be checked and, if necessary, corrected before fitting – to avoid difficulty with gear changes this should not exceed 0.5mm.

CASE STUDY 1 – PEUGEOT 207

A clutch is returned due to noisy operation and clutch disengagement problems.

Inspection revealed gearbox contact marks on the flywheel side of the driven plate hub splines, plus scoring on the driven plate torsion damper and the underside of the clutch cover diaphragm springs.

This indicated a replacement clutch driven plate installed back-to-front, a common occurrence where the marking ‘getriebeseite‘ (‘gearbox side‘) on the driven plate isn’t observed during mounting (see below).

Correct tooling and techniques

Many units returned under warranty bear the telltale marks of careless fitting. Clutch installation and centring tools must be suitable for the clutch being fitted – this applies to all types and is particularly important for Sachs XTend self-adjusting clutches. Tightening sequences and torque settings must be observed, using only hand tools, not impact wrenches. New fasteners should be used when supplied as part of a kit, as many are stretch bolts that must not be reused.

Lubricant application

Lubricants should be of the correct grade, used sparingly and only where specified – for instance, Sachs special high temperature grease on the input shaft splines. Copper- based grease is unsuitable; it has too low a melting point for the load and temperature conditions under which the clutch operates and is not formulated to repel clutch dust. As a result, it thickens in service and causes the clutch driven plate to stick on the gearbox input shaft, giving rise to clutch judder.

With careful attention to the advice given by ZF Aftermarket, it should be possible to reduce the likelihood of an unproven warranty claim and improve customer satisfaction as a result.

CASE STUDY 2 – VAUXHALL ZAFIRA

A concentric slave cylinder (CSC) is returned as faulty. A workshop had replaced the CSC then subsequently noticed a fluid leak from the gearbox bell housing. After gearbox removal, this was found to be the result of the CSC being over-stroked.

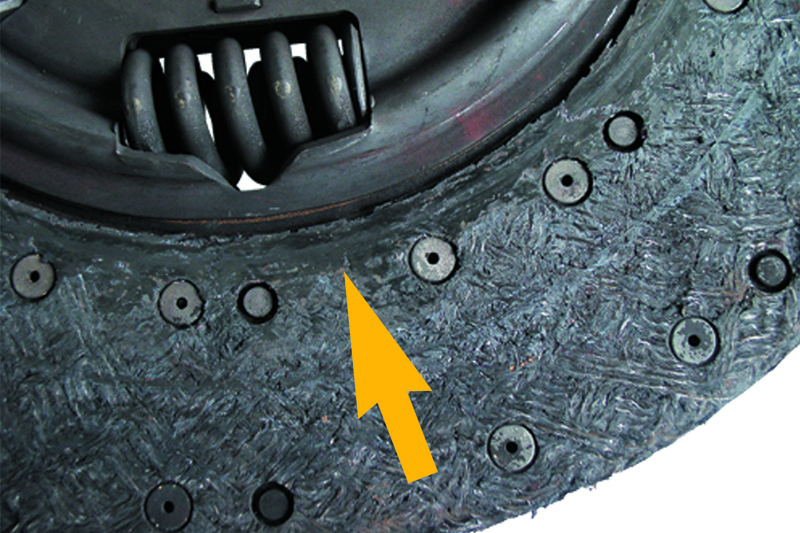

This arises when fluid pumped into the CSC by operating the clutch pedal cannot easily return to the fluid reservoir, forcing the piston beyond its maximum working travel. The cause is usually the rubber seal from the old CSC (see below) remaining in the clutch pressure pipe and causing a restriction when the new slave cylinder is fitted.