What costs more: a sump full of good quality engine oil or a new turbocharger? The answer is obvious, but it’s surprising how many motorists – and some technicians – are tempted to skimp on oil.

Blowing hot and cold

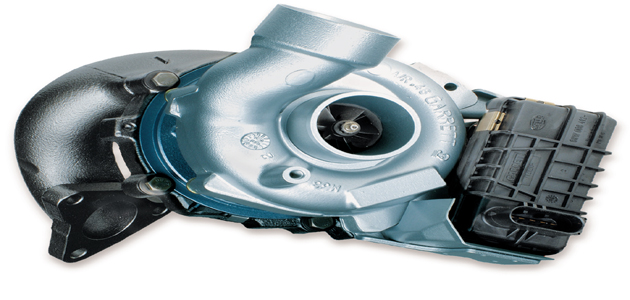

Turbocharged engines are particularly tough on oil. The turbo spins at up to 360,000 rpm (6,000 rps) and reaches temperatures of 900°C or more. From start-up, the oil flowing through it may be relatively cold, yet it has to cope with being rapidly heated to extreme temperatures – while protecting tolerances measured in fractions of a millimetre.

That’s why cheap engine oil often turns out to be expensive. Frequent, intense heating and cooling cycles break down its protective properties. When turbo bearings aren’t constantly covered by a film of oil, they become scratched, scored and wear rapidly. That means the turbo is already fatally damaged.

Follow the recommendations

So, which oil should you go for? Use what the vehicle manufacturer recommends: it will be a good quality semi-synthetic or fully synthetic. These circulate quickly from cold, and include additives that help them ‘bulk out’ at high temperatures, to maintain that vital film of protection.

It’s likely the vehicle manufacturer will recommend oil with a 5W or 0W rating, indicating a low winter viscosity – or thickness – so it quickly reaches the turbocharger bearings.

Change for the best

These oils also have a detergent additive that cleans carbonised deposits (coke) from bearing surfaces. Most of these deposits will be trapped in the oil filter. That’s why it’s essential to change both the oil and the filter when the manufacturer recommends it.

Allowing these highly abrasive particles to remain in the lubrication system will block oil feeds and grind away the turbo bearings. With most modern cars having 10,000 mile or longer service intervals, the cost of a good quality oil and manufacturer’s OE oil filter is just a small percentage of a driver’s motoring costs. Trying to save money on oil is a sure route to much greater expense.

Did you know?

Less than 1% of turbo failures are due to manufacturing faults with the turbo themselves. The vast majority of failures – over 90% – are oil-related: generally either oil contamination or oil starvation.