As is common with a job role like mine, I end up spending a large portion of my time on the road visiting customers and workshops. On one of my recent trips I was faced with a 2003 Toyota Avensis 2.0 diesel that was suffering running problems, with the customer complaining about an intermittent and sudden loss of power. As the issue had yet to be resolved there was only one thing for it – time for a test run!

While out on the road we approached a slight hill, the owner accelerated and nothing; the engine power died away and the engine noise changed to a strange muffled tone. The engine warning light came on and looking out of the back window, I could see black smoke. Experience will tell you that the black smoke is caused by there being more fuel in the combustion chamber than there is air to burn it, and also that the most likely culprit lurks in the EGR system.

The interrogation process

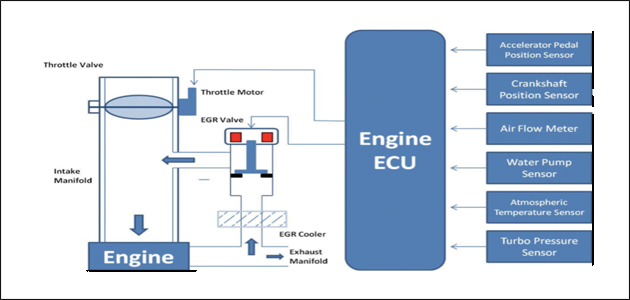

Modern EGR systems are a sophisticated affair as its purpose in a diesel engine is to introduce quantities of exhaust gas into the air intake. This does two things: firstly it reduces the total quantity of oxygen in the combustion chamber and secondly, by bringing in exhaust gas which contains CO2 and H20 (the products of combustion), we spread out the oxygen molecules in the combustion chamber.

The exhaust gas quite literally gets in the way when the fuel and oxygen are trying to find each other during the combustion process. This slows down combustion and reduces the peak temperature. Why is this necessary? Well it’s at temperatures above 1800°C that the nitrogen combines with the oxygen and forms oxides of nitrogen, which is something that’s heavily restricted in emissions regulations.

EGR Control…

EGR is not used all the time and it has to be metered when it is. It’s not used on start-up, initial warm-up or at high loads. To encourage EGR, the Avensis has a throttle plate fitted in the inlet. This makes sure that the pressure in the inlet manifold is lower than in the exhaust.

EGR Feedback…

The ECM has to know what the EGR valve is doing and this is done in a number of ways. The latest diesels use wide band oxygen sensors but in this case it is monitored by the airflow meter. By opening the EGR valve, less air comes in from the air intake. The air flow meter reports and an EGR value is calculated.

Diagnosis…

To prove our theory we used the Blue Print G-Scan to sample some codes and data. We retrieved code ‘P0102 Air flow meter open (low)’ before the code was then recorded and subsequently cleared.

Flight recording…

Now for the data!The G-Scan displays ALL parameters as text or as graphs, although individual parameters can be selected. To get a better picture for analysis we ‘flight recorded’ the event so it could be looked at in detail afterwards. A great feature of the GScan is how easy this is, as all you do is simply press record. We recorded all the engine data and a short drive allowed the problem to occur again. Although the data can be analysed straight away on the G-Scan, on this occasion I transferred the data to my laptop via the SD card.

Working out what happened…

The problem pointed to EGR and airflow. Was the EGR sticking? If it was, the air mass meter would show reduced air flow even when the EGR valve is supposed to be closed. So, we need to know how to work out how much air is coming into the engine.

Air mass calculations are a little complicated, but they can easily and accurately be estimated…

For the calculation we need four figures: engine capacity in litres (divided by two because a four stroke engine takes in half its capacity in air, every revolution), engine RPM, intake manifold pressure and air density. The vehicle in question has a 1998cc engine and we can take the RPM, and intake manifold pressure reading from the G-Scan; now all we need is a figure for air density.

Air weighs about 1.3 grams per litre at 0°C and 1 gram per litre at 80°C at atmospheric pressure. Assuming the temperature of the air in the cylinder is around 80°C; air density in this case can accurately be estimated as 1g/l.

Multiplying half the capacity in litres with the three other values, then dividing it by 60 to change RPM into seconds, will give us an air mass figure in grams per second:

Air Mass = (engine capacity (litres))/2 x (RPM x Intake Manifold Pressure x Air Density)/60

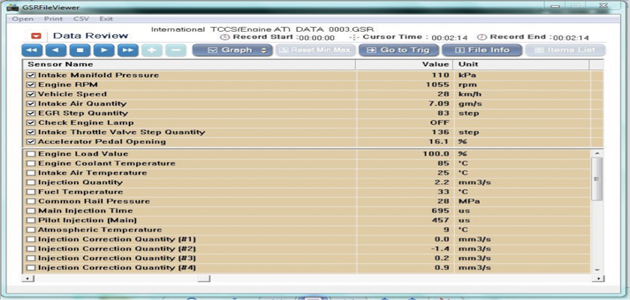

So for the first reading (Fig 1) the engine is at a light load (16% ‘Accelerator Pedal Opening’):

Air Mass = 1.998/2 x (1055 x 1.1 x 1)/60 = 19.32 gm/s

Fig 1

The air mass meter shows 7.09 gm/s when we have estimated that it should be reading around 19.32 gm/s if the entire intake was coming through the air mass meter. In this case EGR is commanded open and represents over 60% of the engine intake. This is the EGR system doing its job at low load meaning there was nothing wrong so far!

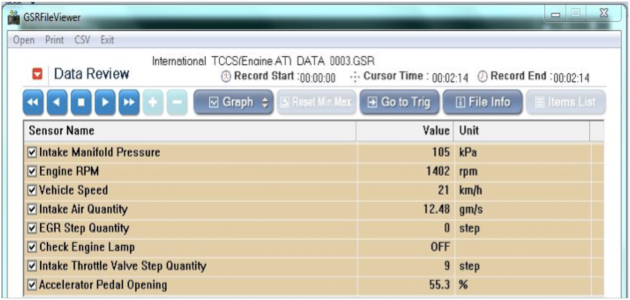

For the second reading (Fig 2), the engine is at a higher load (55.3% ‘Accelerator Pedal Opening’):

Air Mass = 1.998/2 x (1402 x 1.05 x 1)/60 = 24.51 gm/s

Fig 2

The EGR valve should be closed, but the air mass meter only shows 12.48 gm/s (when we have estimated it should be around 24.51 gm/s), which means the engine is taking in only HALF the air it should be; thus the black smoke.

On inspection, the EGR valve had carbon build up which restricted its movement so the valve was removed, stripped and cleaned in a sonic cleaner. Once refitted, the vehicle was back to normal operation.

The source of the problem arose from the driving style of the owner as short rural journeys using light throttle prevented the exhaust gas getting to a temperature that would clear the carbon build up. Thank goodness it wasn’t fitted with a DPF!

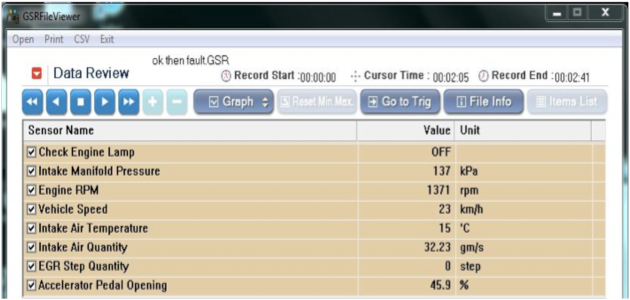

Fig 3

Fig 3 (above) highlights data that is showing the EGR valve behaving itself. Why don’t you have a go at working the calculation out yourself!

Blue Print is the official UK distributor for G-Scan – Japan’s No.1 diagnostic scan tool for Asian vehicles. The G-Scan is supported by Blue Print’s 3-year warranty and includes 2 years of FREE software updates. It is available now from Blue Print distributors.