Melett outlines the basics when it comes to overheated turbochargers.

What is overheating?

Overheating is a term used to describe components that have been subjected to abnormally high exhaust temperature or insufficient cooling.

Causes

■ Hot shutdown

■ DPF issues, such as regeneration, resulting in increased exhaust gas pressure and temperatures, which lead to overheating of the turbine side of the turbocharger

■ Remapping, chipping or over-fuelling

Signs

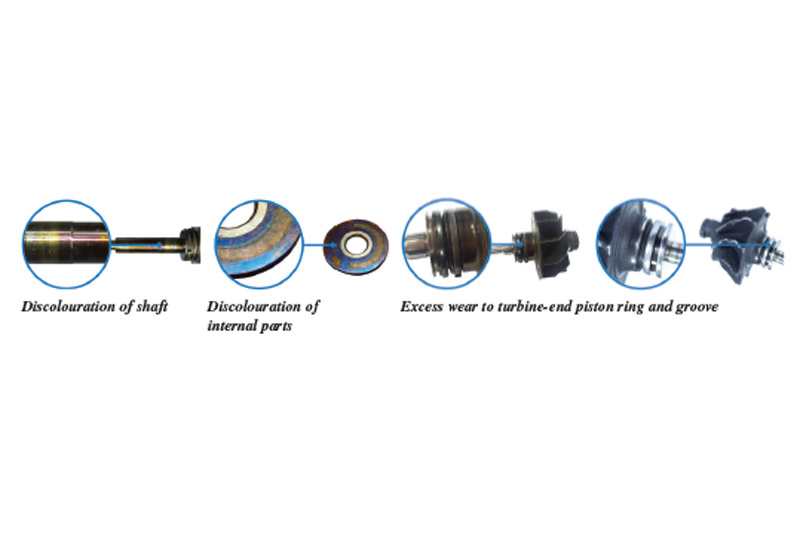

■ Discolouration at the hot end of the turbine wheel, spreading along journal bearing area

■ ‘Heat soak’ from the turbine side of the turbocharger through to the compressor side, causing discolouration to the turbine shaft and bearing housing

■ Discolouration of internal components, including thrust washer and flinger; occasionally, without evidence of wear

■ Collapse (loss of tension) to turbine-end piston ring

■ Carbon build-up in the oil feeds and piston ring area

■ Abnormal or excess wear to turbine-end piston ring and groove

■ Turbine blades appearance being uniformly curved downwards

■ Small sections or edges of the turbine blades being fractured/partial loss of blades

Prevention

■ Check the DPF is in good working condition

■ Ensure there are no leaks in the cooling lines

■ Give the turbocharger time to cool, particularly after long journeys or harsh driving conditions