The correct grade of oil is vital to ensure that tensioners keep the timing chain tensioned to the correct level, yet FAI’s technical department has identified that the majority of timing chain warranty returns are still based on failures caused by oil.

As such, the company asks for a 120ml sample from the engine in order to complete the warranty claim and, without fail, the levels of contaminants indicated by the analysis shows that dirty oil is to blame, as the valve in the tensioner – which can be as small as 0.5mm – has become blocked by dirt or debris.

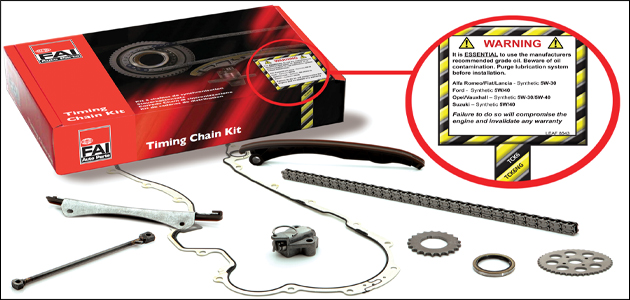

To date, all samples have shown excessive levels of contamination, usually a combination of silicone (Si) – otherwise known as dirt – iron (Fe) and boron (B) oil additive. Furthermore, a recent analysis conducted by FAI shows that high levels of silicone (dirt) can build up within the hydraulic tensioner. In turn, this will block the valve, which will no longer operate optimally. The chain will then begin to flex or oscillate and eventually the chain will fatigue and break. To do its job properly, the acceptable levels of contaminants in engine oil are silicone (Si) 15 ppm (parts per million) and iron (Fe) 100 ppm. So make sure that when changing the timing chain and refitting a new one with its ancillary parts that you use the correct grade of oil, change the engine oil for one of the correct grade and type, clean out and flush the sump and fit a new oil filter. Not only will this result in a long and trouble-free life for the chain, it will also protect you from expensive and inconvenient rework that will not be covered by warranty.