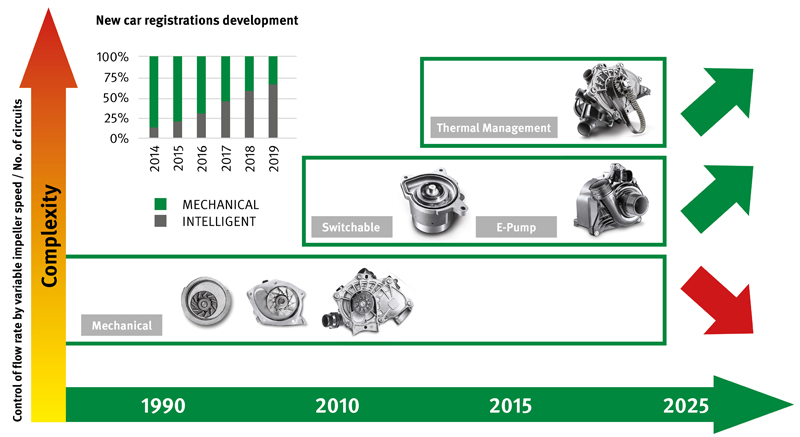

In a market driven by emissions targets, the thermal management module is one of the systems undergoing the most change. Here, Schaeffler explains these changes and highlights the main benefits of the modern system.

The benefits of a modern thermal management system are:

- A reduction in harmful emissions and fuel consumption

- Optimum cooling system temperatures achieved 30% faster

- Engine oil target temperature achieved 50% faster

- Quicker to respond (thermostats are slow to operate and can also negatively affect pressure)

- Individual systems can be controlled independently

- Engine service life increased

- Cabin comfort increased

Every component and system in a modern vehicle is designed to reduce harmful emissions and improve fuel economy, in order to meet the environmental demands of governments around the globe. Modern cooling systems being developed for original fitment by vehicle manufacturers, by companies such as Schaeffler, play a major part in helping to achieve these constantly moving and increasingly stringent targets.

The vehicle cooling process is becoming more elaborate as new systems that need adequate cooling to function continue to be added. EGR, turbochargers and even batteries on hybrid vehicles, for example, are each systems with their own corresponding pipework complexities. Cooling also doesn’t just mean cooling, as the system also contributes to the faster warm-up of engines and gearbox lubricants, which has a dramatic effect on reducing emissions. All this complexity demands more technologically advanced solutions for previously simple parts, such as water pumps, which are now responsible for regulating the flow of coolant to other components and systems around the vehicle.

In the Audi A3 e-tron, for instance, the system conditions the cabin, as well as cooling the internal combustion engine, gearbox and high-voltage components. All are integrated into the various cooling circuits, with the thermal management system controlling each element to ensure that they reach and maintain their individual optimum operating temperature as quickly as possible.

In advanced hybrid vehicles, this can also change depending on the drive mode. For instance, the operational demands of each system can vary dramatically as the motor changes between electric mode and boost mode, with each circuit requiring a different level of flow to ensure the highest levels of reliability, comfort and efficiency are achieved and maintained.

Advanced electric water pumps and integrated ‘system-in-a-box’ Thermal Management Modules (TMMs) have been born from the necessity to keep up with the demands of modern vehicle technology – and not only will they need to continue to adapt to meet the challenges of the future, but so will the independent mechanic.