They’re not visibly prominent and many drivers won’t even be aware of their existence, but rubber-to-metal (RTM) components play a vital role in vehicle dynamics and safety. On occasions, workshops may need to explain this to their customers when justifying the replacement of damaged or worn parts that remain largely unseen.

Take suspension strut and shock absorber top mounts as an example: in addition to preventing vibration and noise from intruding on passenger comfort, their condition affects steering, handling and braking characteristics.

What is RTM?

In simple terms, a rubber-to-metal component is a vulcanised rubber block bonded to metal (or plastic), used to join components or structures that must be isolated from noise and vibration. In practice, reaching an effective compromise between durability, safety and comfort when designing each RTM component to suit a specific vehicle model and purpose involves many complex considerations.

This leads to unique rubber/additive recipes and product designs to tune dynamic properties while also meeting requirements such as high fatigue strength, resistance to ageing, temperature resistance and recyclability. For this reason it is recommended to always use replacement parts from an original equipment manufacturer as fitted at the factory by many vehicle manufacturers. Parts from other sources that appear visually identical may, for instance, be constructed with rubber of unsuitable characteristics, e.g. hardness, or simply glued together rather than chemically bonded during vulcanisation.

Safety, comfort and consequential wear

Shock absorbers maintain tyre-to-road adhesion for good grip and braking. Worn top mounts reduce optimum contact, resulting in longer braking distances and compromised handling, especially during critical avoidance manoeuvres. In addition, vehicle safety systems such as anti-lock braking and traction control can only function perfectly if all suspension components are in faultless condition.

Worn top mounts impair ride comfort, generating noise and transmitting vibrations into the vehicle interior. They also create higher loads on new shock absorbers and other suspension components such as drop links, which then wear more rapidly.

Top mount fault diagnosis

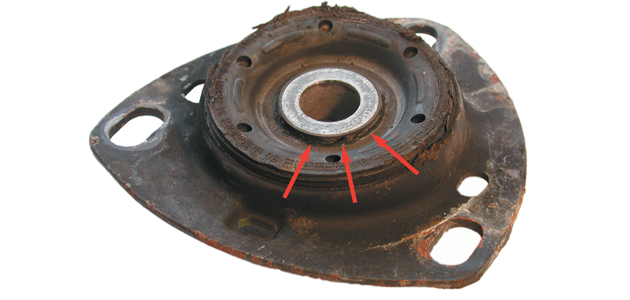

Wear in the top mounts may manifest itself through increased vibration, longer braking distances, or stiff/non-self-centring steering, symptoms that usually develop gradually and go unnoticed by the vehicle owner until a knocking noise prompts investigation. Where possible without dismantling, visual inspection may reveal folds or cracks in the surface of the rubber (see pic, below) or the rubber detaching from the metal.

Following strut removal, a thorough examination can be made and the top mount height compared with a new item (see pic, below). Although elastomer rubber does tend to settle under a static load, for a component in serviceable condition the height difference should be less than two to three millimetres.

Workshop opportunities

Lemförder recommends that top mounts are renewed each time the shock absorbers are replaced; no additional time is involved and it helps to ensure 100% safety and performance on the road, while boosting profit margin.