To extend the service life of commercial vehicle engines and cut harmful exhaust emissions, some engine manufacturers are increasingly using cylinder sleeves with a fire ring.

Design and function

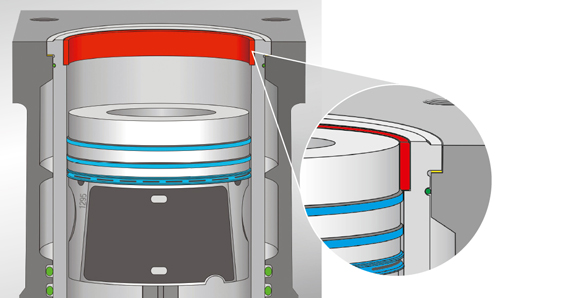

Fire rings are placed at the top end of the cylinder sleeves in a rectangular slot. The fire ring is loosely inserted into the slot during assembly and is subsequently held in position by the cylinder head.

A fire ring or oil scraper ring prevents a hard coating of oil carbon from forming on the head land of the piston. This is achieved by the smaller internal diameter of the fire ring compared to the diameter of the cylinder bore. As the piston passes through top dead centre, the fire ring scrapes the unwanted oil carbon deposits off the piston and prevents deposits from forming on the head land (see diagram below).

The piston is also adapted for the use of a fire ring. For this purpose, the head land has a smaller diameter than a comparable piston with a conventional design.

Problem and solution

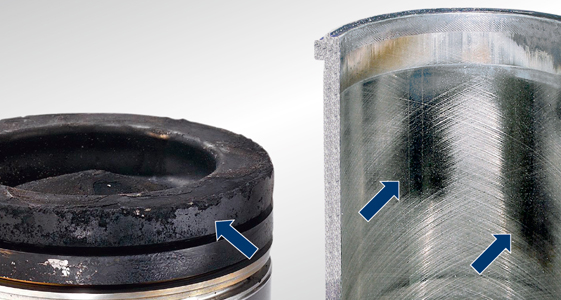

On cylinder sleeves with no fire ring, if the engine is used in unfavourable conditions a hard layer of oil carbon can form on the head land of the piston (see pic below).

Unfavourable conditions include:

1. Frequent short distance driving;

2. Frequent idling;

3. Operation of the engine with unsatisfactory fuel and oil qualities;

4. Lack of vehicle maintenance.

On cylinder sleeves with no fire ring, an oil carbon layer on the head land of the piston leads to abrasive wear after a relatively short operating time (see image below). This unwanted, premature wear on the cylinder sleeves – combined with excessive oil consumption – can be prevented by using cylinder sleeves with a fire ring.

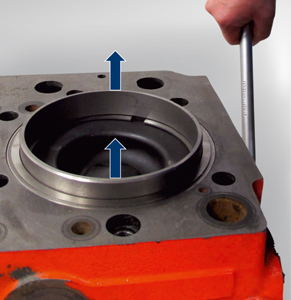

Removing the cylinder sleeve

For the piston to be removed, the fire ring must first be removed from the cylinder sleeve. For used cylinder sleeves, this can’t immediately be done manually. Deposits between the fire ring and the cylinder sleeve cause the fire ring to be tightly stuck in its mounting. When removing defective cylinder sleeves, the fire ring can be destroyed using a chisel worked between the fire ring and the cylinder sleeve (see pic below).

If the cylinder sleeve and the fire ring are to be re-used, the piston is moved slightly downwards by rotating the crankshaft, so that the fire ring is accessible. A used piston ring, with a diameter corresponding to that of the cylinder, is then inserted into the cylinder below the fire ring (see pic below).

Rotating the crankshaft causes the piston to move the fire ring out of the cylinder sleeve (see pic below).

To prevent the piston ring used as a removal tool from becoming compressed and sliding over the fire ring, the joint gap must be bridged with a slip gauge of appropriate thickness while sliding out the fire ring (see pic below).

If only the piston is to be removed, the cylinder sleeve must be fixed in place, i.e. pressed onto its mounting. Otherwise, the piston will slide the fire ring and the cylinder sleeve out of the engine block.

Installation of cylinder sleeve

The cylinder sleeve is first inserted into the engine block without a fire ring. The piston and the con rod are then inserted into the cylinder and attached to the crankshaft as specified. When inserting the piston, it is essential to ensure that the piston ring tensioning strap is pushed sufficiently far into the fire ring slot. This makes sure that the piston rings do not rebound into the fire ring slot and suffer damage as a result.

After installing the piston, the fire ring is placed in the slot manually. With used parts, a slightly stiff fire ring can be carefully knocked into the cylinder sleeve using a hammer and a block of wood (see pic below).

OTHER INSTALLATION AND USAGE ADVICE

- Pistons and cylinder sleeves with a fire ring should be purchased as a set to prevent incorrect combinations of parts and to avoid clearance problems.

- When replacing only the piston, it is essential to ensure that it is intended for use with the fire ring (if necessary compare the diameter of the head land with the old part).

- When replacing only the cylinder sleeve, it is essential to ensure that the height of the fire ring is less than the height of the head land on the piston.

- The fire ring should not be left out. It must always be installed so that the engine will achieve its specified compression and power.

- Fire rings are produced symmetrically, i.e. the ring does not have a particular installation direction.

- When reworking on the engine block sealing surface, as well as complying with or setting the specified piston projection, it is also essential to ensure that the first compression ring cannot collide with the fire ring.

- Fire rings are not honed on the internal diameter.

- Do not retrofit cylinder sleeves with fire rings if they are not approved by the manufacturer.