Braking solutions provider, Juratek informs the PMM audience about the importance of bedding brakes to ensure they work safely.

The brake pad is half the friction couple, with the brake disc being the other half, and both have to work together in order to deliver safe and reliable levels of braking under a wide range of operating conditions experienced in service. How they perform together will also influence the NVH (noise, vibration and harshness) behaviour of the brake and their service life.

Bedding the brake is thus an important step in having your brakes work safely and quietly each and every time you press the brake pedal.

Obviously, bedding the brake helps the brake pad and brake disc make progressively more intimate contact with one another – the real area of contact at a microscopic level is much smaller than the apparent area of contact – this helps ensure much more uniform loading between the two elements and avoids point contact. It also helps with the thermal conditioning of the brake pad which is a complex mixture of different materials. This includes fibres, abrasives, lubricants, friction modifiers and fillers, all of which are bound together by a phenolic resin. With the formation of the microscopic operating film between the pad and disc that is created by the different materials in the pad interacting under operational pressures, temperature and shear; it is this dynamic transient operating film which determines friction levels, wear rates and NVH behaviour.

Bedding usually takes the form of progressively exposing the brake components to increasing levels of braking pressure and temperature. This can take many miles of driving during which the braking performance is at sub optimal levels. To address this issue, Juratek developed its Green Stripe for front axle brake pads which are designed to speed up the bedding process and deliver a great feeling brake which works straight “out of the box”.

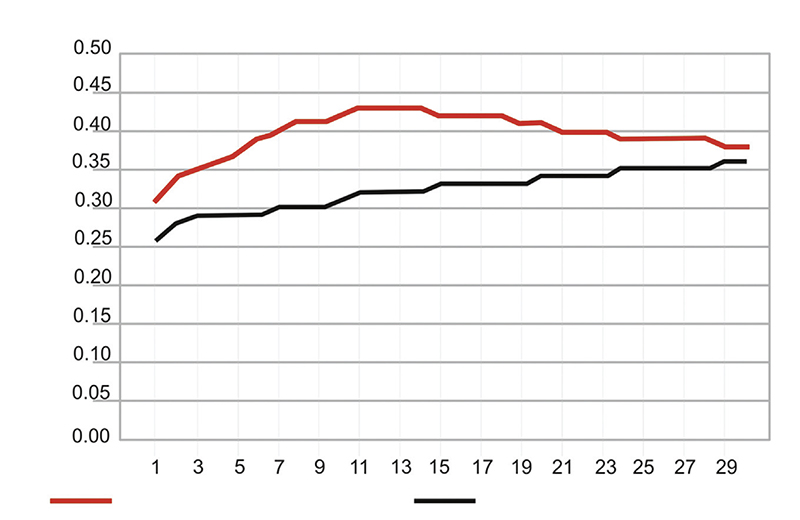

The Green Stripe consists of a mixture of high friction components held in a binder which is applied to the braking surface of the pad and then heat cured. As can be seen from the chart, it significantly reduces the time to achieve design levels of braking performance and helps in creating the interface energy to speed up conditioning of the brake pad components.