There are 167,000 Nissan Qashqai vehicles on the road in the UK, yet only around 100 per year are having their shock absorbers replaced. This could be because replacing the shock absorbers and coil springs on the front of a Nissan Qashqai (02.07-) requires a number of components to be removed under the bonnet to gain access.

KYB is one of the world’s largest manufacturers of OE shock absorbers, with almost 1 in 4 of all cars leaving production lines worldwide fitted with KYB as standard. The same world class product quality is available to the UK aftermarket, including front and rear shock absorbers for the Nissan Qashqai.

THE ICME RECOMMENDED FITTING TIME FOR THIS REPLACEMENT IS 1.7 HOURS PER SIDE.

1. Remove the tyre.

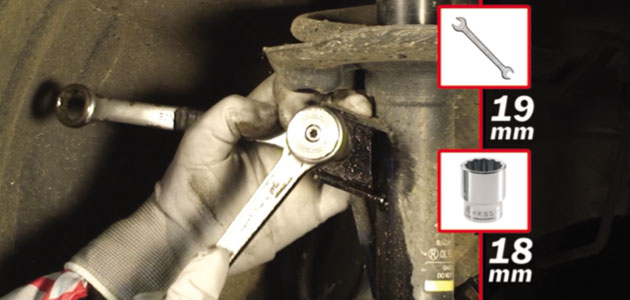

2. Undo the stabiliser link bar bracket bolt.

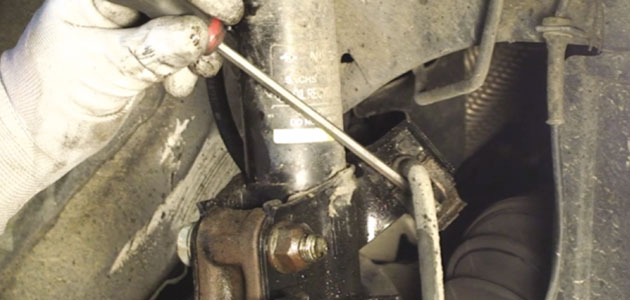

3. Release the ABS sensor cable from its clip.

4. Remove the clip from the bracket to release the brake hose cable.

5. Remove the pinch bolt to release the wheel hub.

6. Release the fuel piping to gain access to the top plate.

7. Remove the clip so you have better access to the top nut.

8. There is an additional nut to remove in the recess behind the top mount. Remove both wiper blades then remove the scuttle panel to ensure access to the last nut.

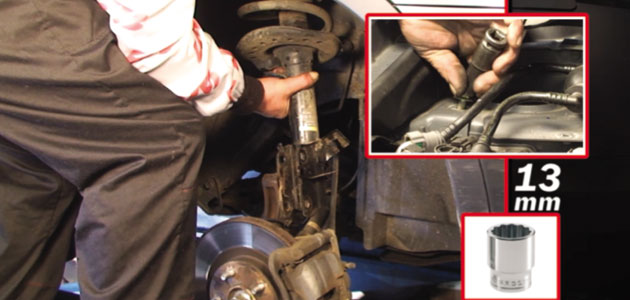

9. Your attention then turns to under the bonnet. Take out the wipers, lift off the rubber bonnet seal and the shock absorber housing and lift out the scuttle panel. Now you can remove the three screws of the upper mount (hold the SA with one hand so that it doesn’t fall). Don’t remove the top nut of the SA at the moment.

10. Remove the strut assembly and dismantle with a spring compressor.

11. Use an Allen key on the top of the strut to remove the top mount.

12. When you re-assemble the unit, the protection kit needs to be firmly located underneath the top mount to secure it.

13. Assemble the new KYB shock absorber, coil spring, protection kit and top mount in the compressor with the gate closed. Ensure that you never use mole grips to steady the piston rod whilst assembling the unit – the grip can damage the smooth chrome coating on the piston rod which will result in it not having perfect contact with the oil seal, causing premature leaking.

14. If the spring, when removed, was seated on a cushion then this should be replaced. Twist the spring so it lines up correctly in the spring seat.

15. The assembled suspension unit can now be offered up under the wheel arch and fixed in position from the top first. All of the other components should then be reattached in reverse order and tightened to the correct torque.

DON’T FORGET TO WEAR PROTECTION!

A shock absorber replacement isn’t complete without a new protection kit. These kits are a critical element for shock absorber performance, offering a host of benefits that includes:

■ Protecting the piston rod from damage and rust;

■ Protecting the sealing joint to avoid oil leakages;

■ Reducing the risks of damaging other suspension components;

■ Shows your customer (the motorist) that the job has been done properly;

WATCH THE PROCESS YOURSELF…..

.