OE Injector manufacturer ASNU has reacted to recent claims spreading on the internet that BMW injectors need to be tested at high pressure in order to successfully detect any leaks.

The company has addressed a common misconception regarding the testing for leaks of Piezo Injectors, particularly the Siemens Piezo Injectors utilized by BMW. It has come to ASNU’s attention there is misinformation circulating within the industry, propagated by various sources including internet “experts” and competitors. It has reportedly been suggested these injectors must be tested at high pressure to detect leaks effectively, especially when vehicles are left overnight and exhibit starting issues. However, ASNU would like to provide some clarity on this matter.

The ASNU Piezo Adapter was initially developed in collaboration with the BMW Engine Plant in Hams Hall, UK, with input from the BMW technical team in Munich. The specifications provided by BMW included electronic requirements for driving the injectors correctly and outlined the necessary tests for injector evaluation. One of the primary criteria set by BMW was the ability to visually inspect the injectors’ spray pattern and operation at low pressure. This low-pressure testing allowed engineers to identify any deviations or hesitations in the injector’s operation, aiding in the diagnosis of potential misfires detected by the vehicle’s Engine Management System during production line operation.

Moreover, the BMW engine plants emphasized the importance of examining injectors returned under warranty to fully understand combustion-related issues in aftermarket vehicles. It became evident carbon buildup was a significant contributor to combustion issues, which was confirmed through testing on ASNU systems.

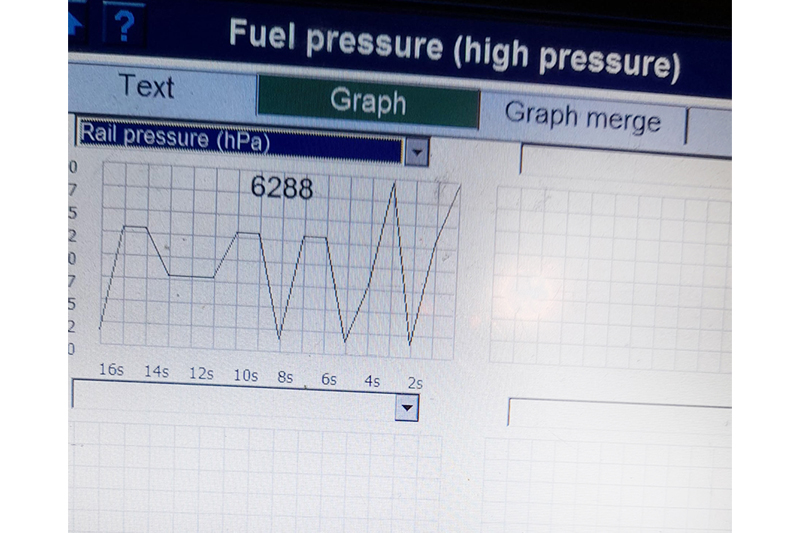

Injector Pressure Drop – Regarding the testing of Piezo injectors for leaks, it is essential to replicate the rail pressure when the engine is switched off. The rail pressure when the engine is off is approximately 6 Bar, so to test for leaks on an ASNU system will only require a pressure of approximately 7 Bar to replicate the fuel rail pressure and safely, visually examine the injectors for leaks. Detecting any leaks occurring over time is an essential test particularly relevant for aftermarket injectors on vehicles which may exhibit Starting or Combustion related issues.

A video of the Pressure Drop is available on its website and shown below:

ASNU’s experience in testing and servicing Piezo injectors has revealed several potential causes of leaks, including damage from chemical flushing, inadequate sealing due to damaged seals or injector ports, and erosion of the injector’s components due to carbon buildup and excess heat. In summary, testing Piezo injectors for leaks with ASNU systems involves setting the pressure to replicate resting rail pressure and examining the injectors for any signs of leakage.

ASNU recommends flowing the injectors, then stopping them, drying them with tissue and air, then running the 10-minute Leak Test Cycle and checking with a dry tissue for any wetness seeping from the pintle seat. Even the slightest leak can lead to starting issues and consequential combustion chamber related problems, and the injector should be replaced.