Projected electronic parts will account for 40% of the global value of vehicles in 2015 and 60% of workshop repairs are linked to electronic issues. This translates to a projected €6 billion in potential business for the independent aftermarket as new vehicles exit the warranty period. In order to gain market share, education and proper service/repair techniques will make all the difference between a profitable garage and one that can’t keep up with the relentless advance of engine management technologies. The modern day oxygen (or O2) sensor is one such item that falls into this category.

Projected electronic parts will account for 40% of the global value of vehicles in 2015 and 60% of workshop repairs are linked to electronic issues. This translates to a projected €6 billion in potential business for the independent aftermarket as new vehicles exit the warranty period. In order to gain market share, education and proper service/repair techniques will make all the difference between a profitable garage and one that can’t keep up with the relentless advance of engine management technologies. The modern day oxygen (or O2) sensor is one such item that falls into this category.

Contamination issues

Since the beginning of closed loop fuel control systems, oxygen sensors have been subject to contamination. Much like spark plug fouling, you can ‘read’ the sensor’s environment. An extremely rich mixture exposes the sensor to extra unburned fuel, which in turn leaves sooty black deposits.

Earlier years saw O2 sensors being contaminated with lead from leaded fuel, which is all but gone today. Lead poisoning can still occur, only when a steel fuel tank is exposed to overly large doses of fuel system cleaners or alcohol. While rare, the result can be the lead/tin alloy (referred to as ‘terne’) plating inside some older steel fuel tanks being emulsified by the exposure to the overuse of cleaners and alcohol.

Once the lead/tin from the plating is in the fuel system this will be in contact with the O2 sensor. Oil deposits can also end up contaminating an O2 sensor, similar to a spark plug when the engine’s rings/cylinder walls are worn, or more commonly, when there is a PCV system or intake manifold causing oil to enter the combustion chamber. Probably the most common source of O2 sensor contamination is from engine coolant leaks such as a leaky intake manifold or cylinder head gasket.

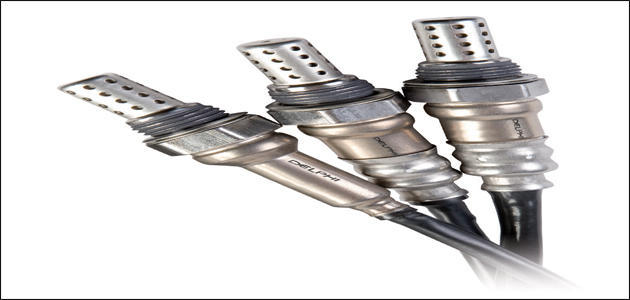

Planar style O2 sensors are manufactured in both the conventional switching Zirconia, as well as the wide band type. The planar element has the ability to provide a sealed air reference, providing its own electrochemical oxygen “pump” in both rich and lean exhaust mixtures, preventing the possibility of air reference contamination. This sensor also utilises an anticontaminate coating that helps to resist sensor contamination.

Ready. Set. Replace.

Similar to a spark plug, the oxygen sensor is threaded and screws into its mounting location. Normally the O2 sensor is supplied with an anti-seize compound on the threads so it can be easily removed at the specified change interval. Over time, the anti-seize compound loses its effectiveness and the sensor can become welded into its location, making it nearly impossible to remove using normal tools. Using excessive force to remove the oxygen sensor may damage the sensor and surrounding components.

Specified change interval

If the sensor becomes seized in its mounting location, a simple 15 minute replacement job can become a much more complex and difficult task. Replacing the O2 sensor within the specified change interval will minimise the possibility of this problem and additional component damage.

Fitting a new sensor – top tips

Allow the engine to cool before attempting replacement of the O2 sensor and keep the following in mind when undertaking the procedure:

- The pre-cat sensor is on the

manifold or the exhaust pipe; EOBD compliant vehicles also have sensors further downstream (post-cat). Be sure you know which one needs to be replaced.

manifold or the exhaust pipe; EOBD compliant vehicles also have sensors further downstream (post-cat). Be sure you know which one needs to be replaced. - Unplug the wire connection then spray a penetrating lubricant onto the threaded connection.

- Use an appropriate oxygen sensor tool such as a ‘crow’s foot’ socket.

- Most oxygen sensors come with a special electrically conductive anti-seize compound applied to the threads, so it’s merely a matter of threading the new sensor into the void left by the old one.

- Use anti-seize compound to coat the sensor’s threads (some oxygen sensors have the anti-seize compound applied at the factory).

- Always check the appropriate reference material for the required torque specification. When there’s no torque value given for tightening the new oxygen sensor, treat it much like you would a spark plug.