The technical team at NSK realises that the replacement of wheel hub bearings is often not an easy process, so has provided automotive technicians with a selection of professional tips to help avoid common mistakes.

The first tip is to compare the fitted bearing to the new one before mounting. Selecting the incorrect bearing is the most common mistake made by technicians. If the bearing is selected correctly, it can be re-checked quickly using the NSK online catalogue, which can be found here.

Avoid damage to the magnetic encoder

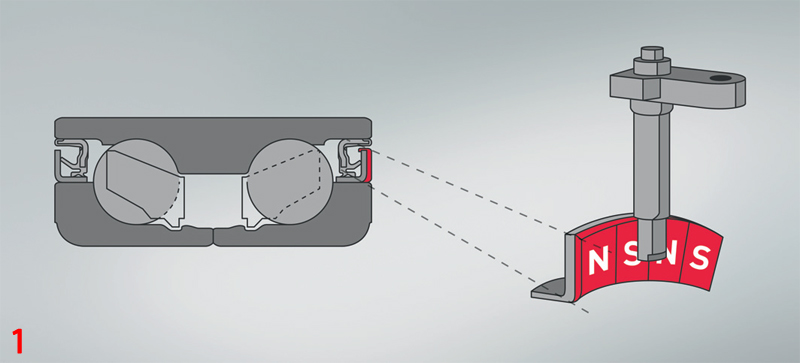

Some hub bearings feature a magnetic encoder for the ABS signal, and thus demand even closer attention. The encoder seals contain many north (N) and south (S) poles, which are read by the speed sensor (Fig 1). If the N and S poles get damaged during installation, it can lead to failure of the ABS system.

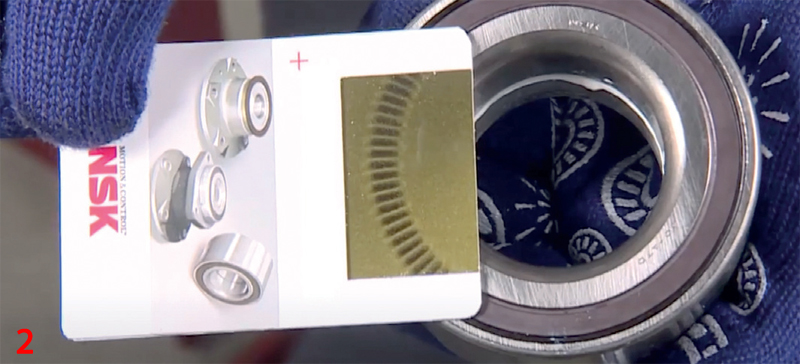

Technicians can identify whether a hub bearing has an encoder by using an NSK test card. The same test card can also be used to establish whether a fitted bearing has pole damage (if the result does not look like Fig 2), which in turn can help technicians identify ABS signal problems.

Keep the encoder from magnets and dirt

A good tip is to avoid coming into contact or getting near the encoder with tools such as spanners and screwdrivers as they can change the N and S poles, again leading to issues with the ABS signal. With this thought in mind, only remove the bearing from its protective packaging immediately before fitting.

Ensure correct encoder orientation

Encoders are only present on one side of Hub I generation wheel bearings – as identified by the test card – so it is vital to get the orientation correct when pressing into the knuckle. Before beginning this operation, always check that the encoder surface will be adjacent to the sensor after assembly.

Avoid pressure on the encoder surface

For pressing, use a tool that only contacts the end face of the outer ring on Hub I generation bearings (Fig 3). Never press on the encoder seal and never press on the inner ring as it will lead to bearing failure within a few kilometres of use. Once a suitable tool has been selected, keep the bearing aligned to the bore and press it vertically into the knuckle.

Further tips for correct bearing installation

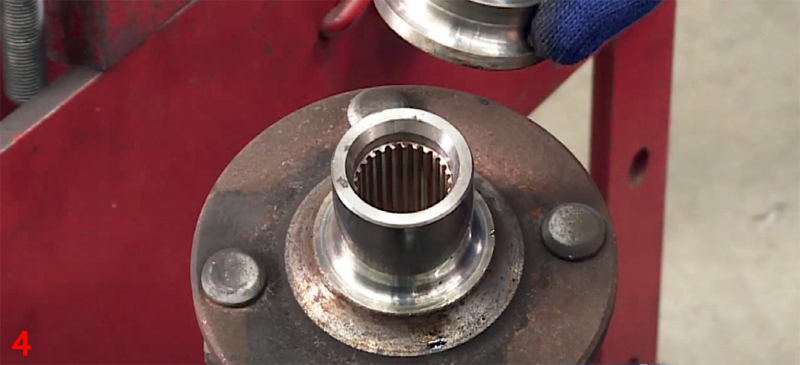

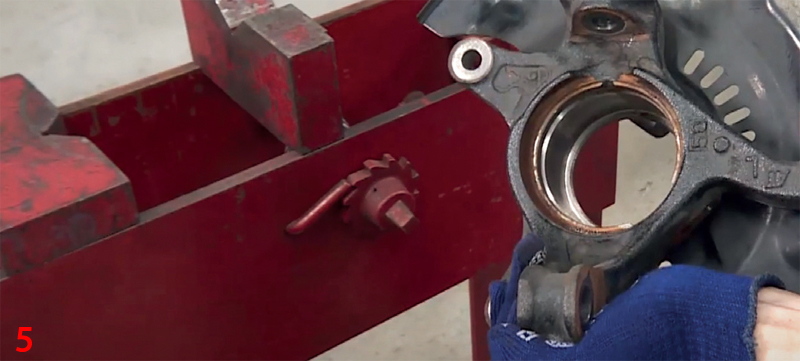

There are many general tips to keep in mind throughout the process, such as taking care of all suspension parts to avoid any unnecessary damage. Additionally, to ensure correct fitting of the bearing, it is especially important to control the hub and knuckle during assembly, while all surfaces that come into contact with the bearing should be cleaned beforehand (Fig 4 and 5).

FIG 4 & 5: It is important to control the hub and knuckle during assembly, and ensure all surfaces that come into contact with the bearing are cleaned beforehand

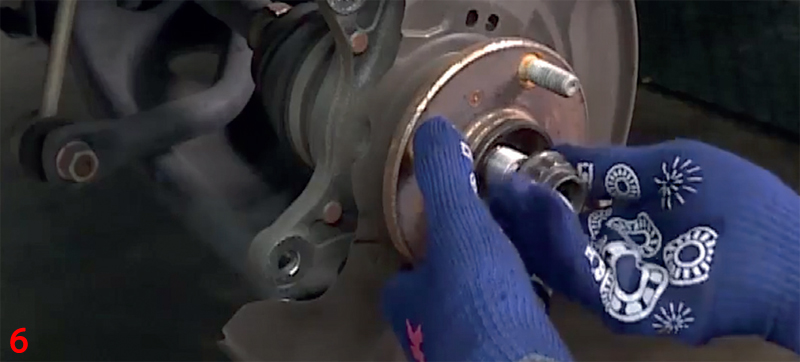

As a final point of note, for safe reassembly, technicians should only use the tightening torques recommended by the car manufacturers. In particular, it is known that applying excessive torque to the CVJ nut can lead to bearing damage (Fig 6).

The correct fitting of Hub I generation wheel bearings with magnetic encoders is especially challenging, which is why NSK has produced a video on this subject that shows every step of the process.