A number of changes have been made to the brake performance test, so it’s important that test stations understand how to carry these out accurately. For this example we’ll be using a conventional roller brake tester (RBT).

SERVICE BRAKE TEST

Firstly, it’s not important which axle is tested first. The service brake test for the front wheels and rear wheels uses the same procedure and Reasons for Rejection (RfR), so the following instructions apply to both axles.

1. Position the wheels on the brake tester and ensure they are located reasonably centrally in the rollers. Start both rollers in a forward direction and allow the wheels to centralise.

2. Leave the rollers running and note whether a significant brake effort is recorded from either wheel, indicating that a brake is binding.

3. Slowly apply the service brake and watch how the braking effort from each wheel increases. Use your experience to reach a moderate braking effort and avoid getting to maximum effort or wheel lock. If the brake efforts don’t increase at about the same rate, then that is a reason for rejection.

4. Once at a moderate brake effort, hold a steady pedal pressure and check for fluctuation of brake effort through each wheel revolution. Then gradually release the brake and check that the brake effort at each wheel reduces at about the same rate.

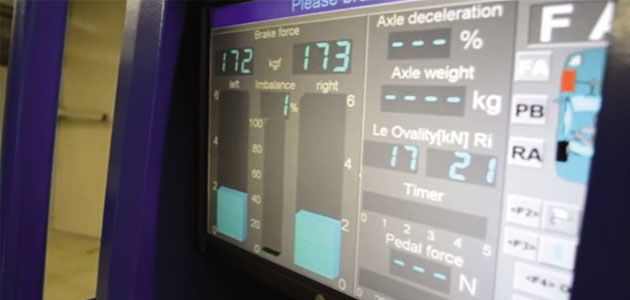

5. Once the brake is fully released, gradually apply the service brake again, this time until maximum effort is achieved or the wheel locks and slips on the rollers. Stop the rollers if they haven’t already stopped automatically and record the maximum brake efforts achieved and whether wheel lock occurred.

6. If there is a parking brake on the axle you are testing, you would test that next, but if there isn’t, move the vehicle to test the next axle.

PARKING BRAKE TEST

1. Start both sets of rollers again. If it’s a conventional hand lever type, keep the disengage button pressed in throughout the test. Gradually apply the parking brake until maximum effort is achieved or the wheel locks and slips on the rollers.

2. Stop the rollers if they haven’t already stopped automatically. Record the maximum brake efforts achieved and whether each wheel locked.

3. Additionally, if the vehicle has a single line service brake system, you will need to note the way the parking brake efforts increase as severe grabbing of the brake will be an RfR. The tester will also have to calculate parking brake imbalance for such vehicles as the VTS Device will not carry out this function.

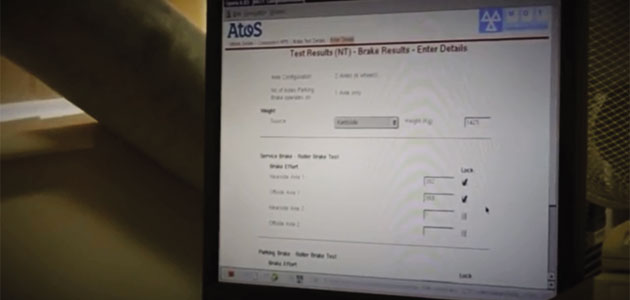

ENTERING THE BRAKE DATA ON THE VTS DEVICE

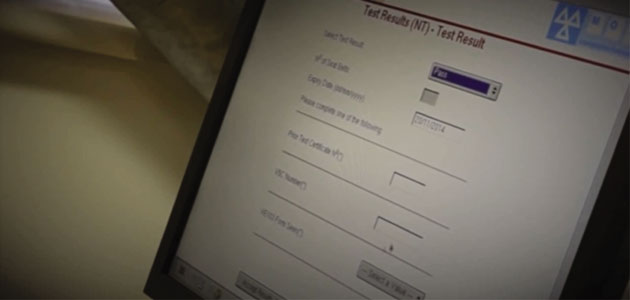

1. Your inspection check list should now detail any brake performance defects noted throughout the inspection, as well as the maximum brake efforts for each wheel and whether the wheel locked. This information should be entered on the VTS Device, which will automatically calculate the brake performance test result in respect of overall brake efficiency and brake imbalance.

2. Where you indicate that a wheel has locked, the VTS Device will take this into account when making the calculations.

3. Reasons for Rejections for any other brake performance defects must be selected using the component list in the usual way. These include:

– Excessive bind;

– The braking efforts not increasing at about the same rate;

– Excessive fluctuation of brake effort;

– The braking efforts not decreasing at about the same rate;

– Little or no brake effort from any wheel.

ADDITIONAL INFORMATION

Don’t forget that for vehicles with a single line braking system, parking brake imbalance or severe grabbing defects must also be selected manually using the component list.

Although this brake test procedure is recommended for use with conventional RBTs, not all RBTs are able to run both brake rollers together to check maximum efforts. Where this is the case, maximum efforts must be checked running each roller set individually.

WATCH THE VIDEO

THE DRIVER & VEHICLE STANDARDS AGENCY

The recently named Driver & Vehicle Standards Agency (DVSA) replaces VOSA and the Driving Standards Agency with responsibilities for setting, testing and enforcing driver and vehicle standards in Great Britain.