The success of GDi (Gasoline Direct Injection) engines means that they’re seen as potential replacements for diesel engines in the small car market. But is it too good to be true?

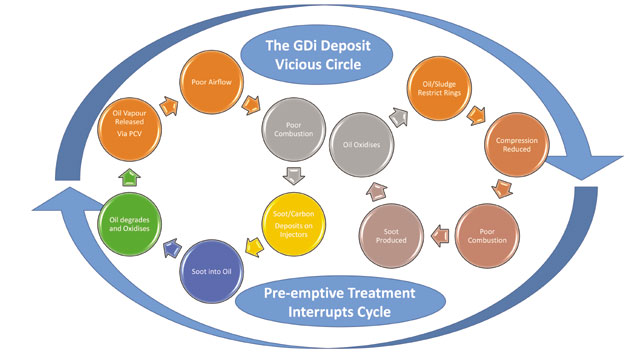

Well, it seems that for the upside of economy and low emissions, there is a downside of maintenance issues and loss of performance. This does, however, mean there is an opportunity for the independent sector to offer preventative maintenance and repair

How does Direct Injection (DI) work?

By injecting petrol at high pressure directly into the combustion chamber, DI delivers fuel more precisely and efficiently than port fuel-injection systems (PFI). The result is more complete combustion and cooler cylinder temperatures, enabling higher compression ratios for greater efficiency and power. Combining DI with turbocharging delivers even greater gains in economy and performance. This enables OEMs to use smaller displacement engines, resulting in even more efficiency.

But, because of the position of the injectors (inside the cylinder) they’re in direct contact with the soot released from the burnt fuel. The soot deposits itself on the injector tip and interferes with the accuracy and atomisation of the spray pattern.

A second issue is that because the injectors don’t spray across the intake valve, the valve is subject to additional deposit formation as the detergents that are in the fuel don’t touch the valve. These build-ups can be exacerbated by oil vapour deposits.

In order to reduce frictional energy loss and improve MPG, GDi engines use lighter, low tension piston rings. Ring spring force in older engines was as high as 30psi, but new GDi engines can be 60% less. Also, engine compression ratios have increased from 9:1 to as high as 14:1. This increased pressure creates more force on the low-tension rings.

Piston rings should prevent oil seeping up, as well as fuel and combustion gases from ‘blowing-by’ between the piston and cylinder. Crankcase contamination compromises lubrication and promotes oil degradation, making the oil more susceptible to thickening. When oil thickens it flows less easily, so that when it gets behind the rings it tends to stick. Over time it hardens and restricts ring function, reducing compression, and allowing even more gases, soot and fuel into the oil.

The impact on compression is also a feature. BG Products tested a Ford 2.0 GDi and it had lost 8% compression PSI in three cylinders after only 11,000 miles. A Mazda 3 lost up to 14% in 36,167 miles under the same test conditions.

While GDi engines are known for efficiency then, the struggle between low tension piston rings and high operating pressures will eventually erode fuel efficiency and diminish horsepower.

Preventative maintenance works

BG Products’ research has shown that a preventative maintenance regime can drastically limit the problems that will impact GDi engines. Technicians should aim to keep the injectors clean of hard baked deposits, maintaining integrity and slowing down oxidation of the oil. The old oil should also be thoroughly cleaned out of all critical areas during an oil change.

BG Products has lots of information about causes, progression and solutions for GDi to share with technicians who pay the company a visit at MECHANEX. Visit Stand N7 to find out more

Registration is simple, visit http://www.mechanex.info or call 01923 237799. For all the latest news and info on upcoming shows, follow @MECHANEXShow.

Click here to read our online show preview.