Best practice guidance and common assembly errors from Brake Engineering.

The Concentric Slave Cylinder (CSC) is subjected to just as much natural wear as the clutch or flywheel and should be replaced every time the clutch is changed. There are, however, a few important things to consider during installation in order to preserve the functionality and service life of the components.

These include:

- Do not repeatedly pump the clutch pedal when bleeding; depress just once and wait for the hydraulic system to stabilise before pumping again. This eliminates the risk of over-pressure inside the CSC.

- Do not use any lubricants or cleaning agents as they may damage the gaskets or entire cylinder.

- A high level of cleanliness is critical at all times.

- Only use brake fluid approved by the car manufacturer.

- Gaskets, seals and the connection areas must be totally clean.

- Clean the transmission input shaft and ensure that there is no damage or excessive wear on the shaft seal area.

- Make sure the slave cylinder is installed flat against the transmission-mounting surface.

- Fit the slave cylinder fixing bolts and tighten as per VM requirements.

- Flush the connecting hose through with clean fluid before assembly to prevent contamination of the new cylinder.

- Fill the reservoir with an approved DOT 3 or 4 brake fluid.

- NEVER bleed the CSC if the clutch and flywheel are not yet assembled.

- Make sure the CSC is not tilted during installation. Failure may lead to damage of the fixing lugs or reduced service life.

- Do not over-tighten the bleed screw.

- Bleed the screw torque for the plastic housing (3-5 Nm), or for the Aluminium housing (15-20 Nm).

Common CSC assembly errors

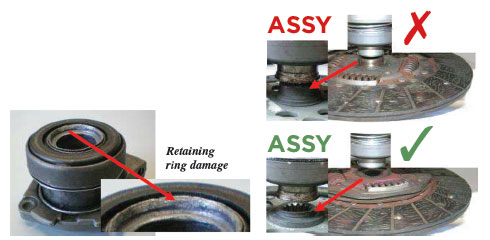

- Friction plate wrong way around

If the friction plate is assembled the wrong way around, it will damage the retaining ring and cause leakage.

- Overstroke

Repeated pumping of the clutch during bleeding can cause the clutch slave to over-stroke. This will result in the damage of the retaining ring or primary seal as the sliding sleeve can slip out of the bore. The main seal will also be damaged if attempts are made to re-fit it.

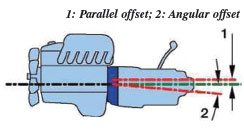

- Axial and angular shaft/ engine misalignment

The transmission shaft must be perfectly aligned during fitment, as excessive axial or angular misalignment will stress the primary seal, causing a reduction in the life of the unit.

Possible causes of misalignment are:

Possible causes of misalignment are:

■ Centering between engine and gearbox is not correct (deformation, heavy dirt or wear);

■ Other parts (e.g. grounding straps) trapped between engine and gearbox during installation;

■ Flange bolts loose or not properly tightened;

■ Close-tolerance sleeves or pins missing/damaged;

■ Pilot bearing in the flywheel is absent or badly worn;

■ Clutch bell housing warped due to unevenly or over torqued fixing bolts;

■ Clutch bell housing deformed due to dropping or striking hard when fitting.

If there is excessive axial or angular misalignment, when the transmission shaft rotates it can generate mineral oil mist which can contaminate the primary seal, leading to failure of the cylinder.

Incorrect fluid use

Incorrect fluid use

The clutch hydraulic system MUST only be filled with the manufacturer’s recommended fluid. Never use mineral oil.

If the wrong hydraulic fluid is used, the seals in the system will be damaged. In systems which are combined with the brake system, seals in the brake system may arise.

- Bleeding error – over-pressure

Do not use power assisted bleeding devices on the clutch system. Use of these systems can over-pressurise the CSC. If this occurs, it will cause permanent damage to the cylinder and it will need to be replaced!

Manual bleeding should be carried out using the following process:

- Depress clutch pedal;

- Open bleed valve;

- Keep clutch pedal depressed until fluid appears – DO NOT release;

- Close bleed valve;

- Release clutch pedal slowly;

- DO NOT repeatedly pump the clutch.

The clutch bleeding cycle must be repeated 20 to 25 times to guarantee complete bleeding. Top up the level of the fluid in the reservoir between the cycles, remembering that the level of the fluid must not drop below the minimum mark on the reservoir during bleeding!

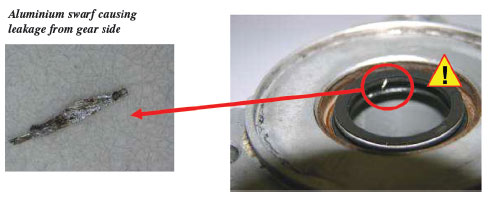

- Contamination – gear shaft

Ensure that all contamination is removed during the disassembly and re-assembly processes. Any debris or swarf can contaminate the main seal and cause leakage.