ACtronics takes an in-depth look at Mercedes’ 7G-Tronic transmission control unit and outlines what you need to know before working on one.

Most experts will think immediately of Mercedes-Benz when they hear the term ‘7G-Tronic’. And rightly so, because the 7G-Tronic transmission control unit is part of the Mercedes-Benz 722.9 gearbox: the first 7-speed automatic ever available for passenger cars. The gearbox was introduced in 2003 on all Mercedes models with 8-cylinder engines. Among them are the W203 and W204 C-Class, W211 and W212 E-Class, W220 and W221 S-Class and cars like the famous G-Class. However, the 722.9 has one drawback: it has a limit of ‘only’ 735Nm. So cars with V12 engines had to carry on using the older 5G-Tronic, which could handle a torque up to 1,079 Nm.

General operation

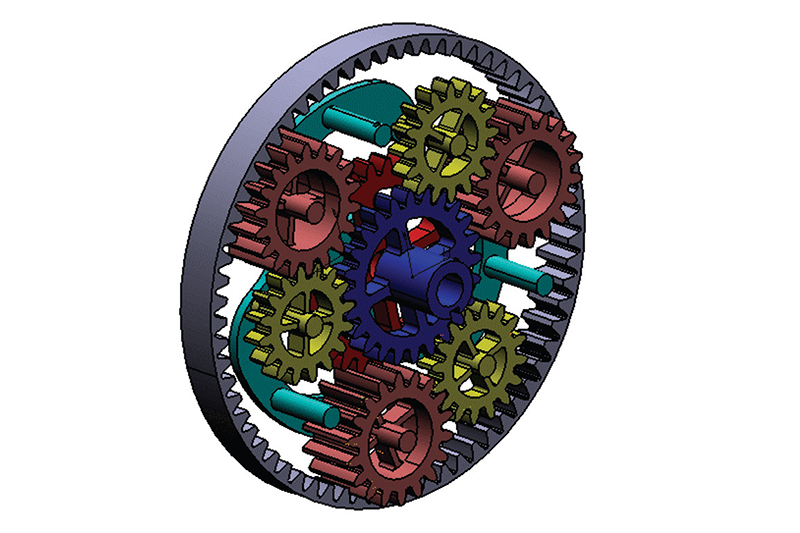

The gear system of the 722.9 consists of three planetary gear systems and one Ravigneaux gear system: simply put, a planetary gear system on a planetary gear system. This dual function makes many more different gearbox ratios possible, which means that nine gears can still fit inside a relatively compact gearbox (seven forward, two reverse). See Fig.1.

In order to save weight, Mercedes- Benz has made the gearbox body out of magnesium. They were the first manufacturer ever to do this.

How the mechatronic works

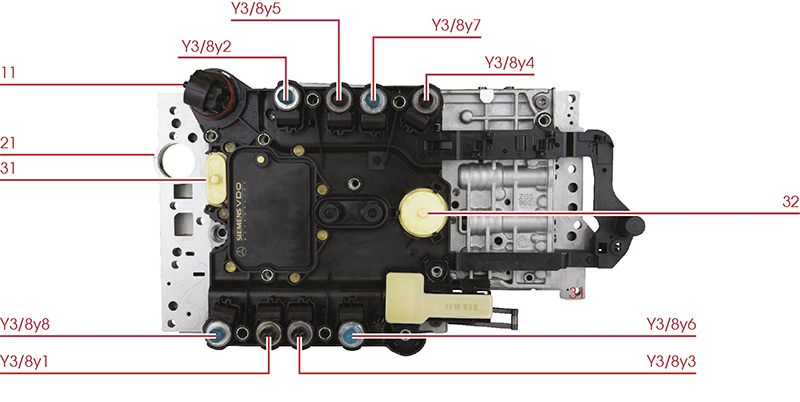

Of course the gearbox won’t change gears by itself so it needs some kind of mechatronic device. The mechatronic of the 722.9 gearbox consists of a TCU, a hydraulic block (valvebody) and several control valves (solenoid valves). The hydraulic block acts as a labyrinth, allowing the fluid pressure to flow directly to the components to be controlled. The control valves control these fluid flows. Normal open solenoids and normally closed solenoids are used to maintain limited functionality in the event of a malfunction. Compare the table below with the annotations on Fig.2.

Part no./Function

11 Connector

21 Hydraulic block/valve body, consisting of two parts and a partition panel

31 Oil level float 1

32 Oil level float 2

Y3/8y1 Control valve for general operating pressure

Y3/8y2 Clutch control valve K1

Y3/8y3 Clutch control valve K2

Y3/8y4 Clutch control valve K3

Y3/8y5 Brake control valve B1

Y3/8y6 Brake control valve B2

Y3/8y7 Brake control valve B3

Y3/8y8 Lock-up clutch control valve

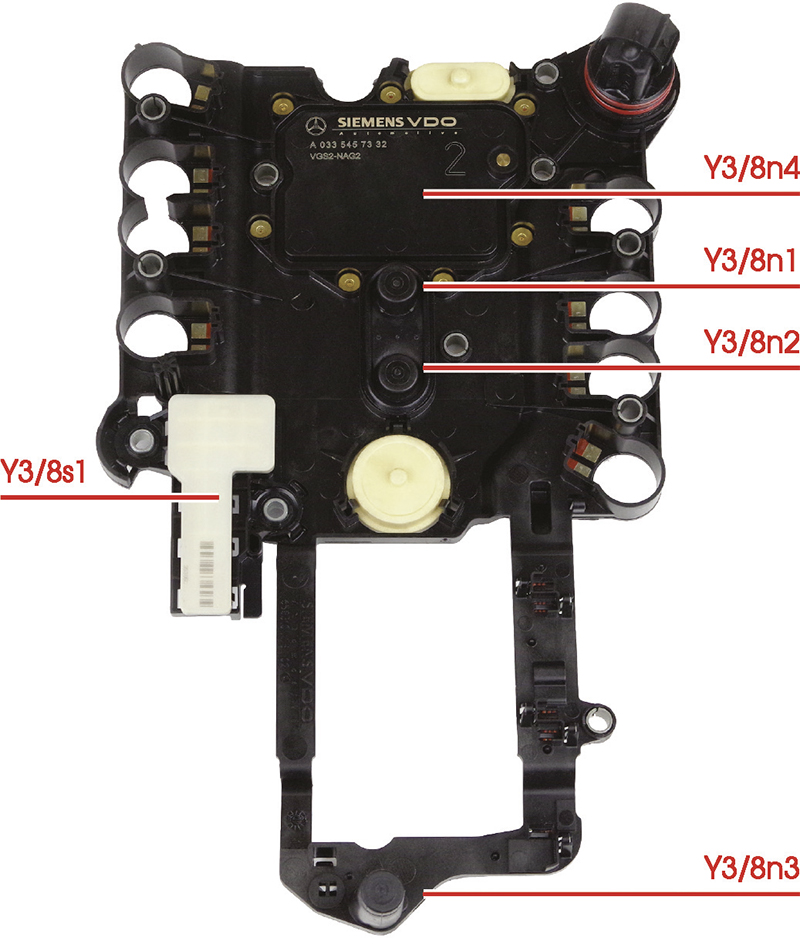

It’s up to the TCU to decide when and how to act. It relies on several inputs like gear selector position and current speeds. The 7GTronic TCU depends on three speed sensors: input shaft speed, central speed and output shaft speed. Compare the below table with the annotations on Fig.3.

Sensor/Function

Y3/8n1 Input shaft speed sensor

Y3/8n2 Central speed sensor

Y3/8n3 Output shaft speed sensor

Y3/8n4 Control module

Y3/8s1 Position sensor switching position

Known complaints and fault codes

There’s a lot of knowledge at ACtronics about complaints and fault codes regarding the 7G-Tronic TCU. Long story short: most of the time it’s the speed sensors that will cause a lot of problems. Fortunately, there’s a perfect remanufacturing solution for these kinds of problems.

Speed sensor-related fault codes: P0717, P0718, P0720, P0721, P0722, P0723, P2200, P2201, P2204, P2205, P2206, P2207, P2550, P2767, P2768.

Check the sensor function yourself

If the car from which the TCU comes is still available, the sensors of a removed TCU are relatively easy to check yourself. The only condition: a diagnostic tool is needed to make live data visible. Proceed as follows:

- Connect the connector from the car to the separate TCU

- Turn on the ignition (power supply)

- Find the required live data in the reader

- Use a (magnetic) screwdriver to move along the sensors several times

The frequency at which the screwdriver passes the sensors now becomes visible as the speed.

Note: With sensor Y3/8s1, it is sufficient to hold the magnetic screwdriver in a certain position near the sensor. The sensor has four “fields”. Each field displays its own shift position (“P”, “R”, “N” or “D”). Speed sensors Y3/8N1 and Y3/8N2 respond to a magnet. Speed sensor Y3/8N3 reacts to metal.

Instant replacement not possible

A 7G-Tronic TCU from a donor car unfortunately cannot just be placed in another car. The device will have to be ‘virginised’ first (i.e. removed of all coding, just like a new, unused part). You need to then carry out “Commissioning after repair N15/3” with a diagnostic tool. Part of this “Commissioning after repair N15/3” is the SCN coding. This coding can be obtained by reading out the original TCU. If this is not possible, it can be requested via the Mercedes-Benz online platform. The SCN coding for the car is only issued once Mercedes-Benz has approved the conditions.

Virginising is something that ACtronics can also do. That is why we also have the possibility to offer a replacement part, if necessary. “Commissioning after repair N15/3” still needs to be carried out, but the TCU is usable in any case.

Non TCU-related complaints

Unfortunately there are also complaints that can’t be solved that easy. For example, the lock-up clutch is known for slipping. This occurs because of extreme wear. Check whether the magnets in the sump pan are full of (iron) swarf. If this is indeed the case, then it can be assumed that the lock-up clutch has extensive damage. It is advisable to replace the entire gearbox including the torque converter, because the iron swarf has now spread throughout the entire transmission.

All modern electronics and mechatronics have their share of problems. However, the 722.9 gearbox really is a clever piece of engineering. It’s fairly reliable, performs smoothly and is packed with some great technology. But in case something (electronic) goes wrong, just call ACtronics. We’ll know what to do.