Gates advises technicians on some common issues related to the cooling system in vehicles.

Although not a supplier of coolant, it’s clear that the performance of the cooling system components that Gates does supply can be compromised if the coolant in the system is in a poor condition.

Consequently, investigations into the premature failure of components such as water pumps, thermostats and hose assemblies will always look for any evidence of:

- Incorrect selection of coolant type

- Contamination of the coolant

- Incorrect mix of coolants

In such cases, it’s clear that the straightforward replacement of components such as water pumps, hoses and thermostats will not solve the problem. It’s likely there will be further comebacks that mean significant inconvenience for garage customers, additional rectification costs to the garage, as well as time lost through unnecessary warranty claims at distributor level.

For these reasons and to reduce the number of common installation errors, Gates wants mechanics to be more aware of the problems that coolant can cause when it is in a poor condition. More importantly, it’s essential that mechanics appreciate how these problems can be avoided.

Role of coolant

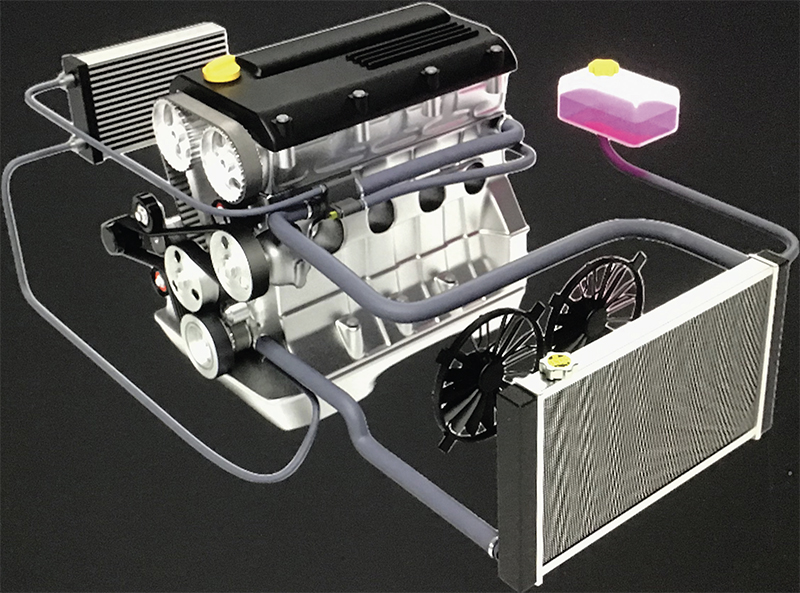

Heat generated by internal combustion engines is controlled by a heat transfer process involving coolant that is driven by the water pump(s) around the engine. In modern ICE engines, there are often up to three water pumps (one mechanical, two electrical) that control the delivery of coolant to separate circuits. Modern cooling systems can be split into individual cooling circuits, meaning there can be two or three of them within a cooling system.

Composition of coolant

In general, the coolant comprises of:

- 50% water, which facilitates an efficient transfer of heat

- 45% base fluid, which has lubricating properties and when mixed with water increases the operating temperature range of the coolant from between -37 Cto +129 C

- 5% additives, also known as an inhibitor package, which controls the pH balance (8.5 – 10.5) and protects internal components from corrosion, cavitation and the build-up of scale

- Different manufacturing properties, such as inorganic additive technology, organic additive technology and hybrid organic additive technology mean that some coolants are incompatible with others

The coolant manufacturers will determine the precise nature of the base fluid. This often involves a choice between the use of ethylene glycol or propylene glycol. The inhibitor pack may contain phosphates, silicates, nitrites or borates, for example, depending on the additive technology required as well as the specific vehicle application. Dye is used as part of the inhibitor pack to add colour in order to distinguish the coolant from water.

Note: Coolant colour does not dictate which coolant technology is being used in a vehicle cooling system.

Five facts about coolant

- It’s a myth that the colour of the coolant determines its use in particular types of engines

- Significant levels of old coolant are often retained by the cooling system after draining and compromise the quality of new coolant

- Never mix coolants with different additive and inhibitor packages. This may accelerate corrosion, or reduce the protection that the coolant provides to a range of components

- A 50/50 pre-mixed coolant provides the safest level of protection inside the engine

- A refractometer (Gates Part No. 91001) checks ethylene glycol/propylene concentrations, but not those in the additive/inhibitor package

Five coolant corrosion problems

- Reduced heat transfer values through build-ups of scale

- Blocked hoses

- Damaged water pumps and thermostats

- Oxidation in aluminium radiator and heater cores

- Galvanic or electrolytic corrosion (attacks engine blocks/water pumps, thermostats, radiators/heater cores)

Five preventative maintenance tips

- Discoloured bleed marks around water pump weep holes indicate impending failure

- Before replacing the water pump, use an appropriate tool to flush the system free of contaminants, rather than a hose pipe

- At installation, prime the mechanical seal of the water pump with coolant

- Never ‘dry run’ a water pump prior to installation

- Modern cooling systems may require a specific bleeding tool and/or diagnostic equipment

A Gates technical webinar on 25th March will look at Coolant Hoses. It will put a focus on modular cooling hoses, highlight typical failures and provide diagnostic tips for professional installers. To book a spot on the webinar, click here.

Case study

Product: Switchable water pump

Vehicle: VW Golf

Engine: Diesel 1.6

Year: 2014

The water pump on the left is the switchable version. Note the electrical cable and the square-shaped solenoid connector or cylinder head cooling valve (N489) on the right hand side. This controls movement of the shroud, or steel band. At start-up, when the engine is cold, the shroud, is driven over the impeller. This prevents initial coolant circulation. It’s essential that the shroud is able to return on the axis of the impeller once the engine reaches optimum temperature.

Note the crystalised substances seen below the shroud in the picture. This has been caused by an incorrect coolant mix. Different chemicals have reacted to produce a coagulated gel-like substance (it has turned solid after later exposure to the air). In this case, the gel caused the shroud to stick and this caused the water pump to fail prematurely.

Gates supplies two types of PowerGrip Belt Kit Plus Water Pump for applications like these. The KP15678XS-1 features the OE spec switchable water pump, while KP15678XS has the non-switchable water pump.