MS Motorservice outlines some important things you need to know about water pumps and some common issues you might come across when working on them.

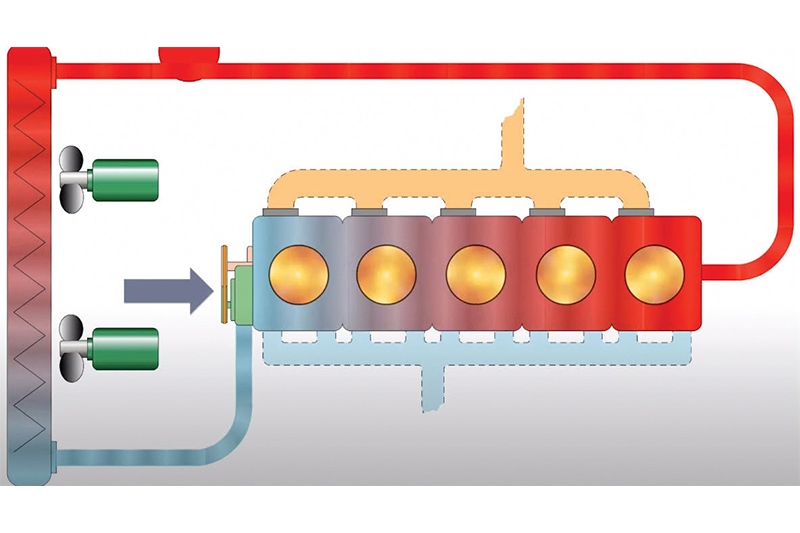

High temperatures occur in the engine during combustion. To prevent the engine being damaged by overheating, it needs to be cooled. One option for doing this is air cooling. However, most engines are water-cooled. The cooling liquid absorbs the heat from the engine block and cylinder head and releases it into the ambient air through the radiator. The water pump, also known as a coolant pump, is responsible for conveying this liquid.

Types of water pumps

Mechanical water pumps are usually driven directly by the engine. The power consumption of the water pump thereby increases in line with the engine speed. But even during idling, sufficient engine cooling must also be guaranteed for all operating states. Conventional water pumps are therefore oversized for most operating states.

On electrical water pumps, the power consumption can be controlled electronically depending on the extent to which the engine needs to be cooled. This demand-based control reduces fuel consumption and, in turn, pollutant emissions.

Coolant agent on the outside of the water pump?

If coolant agent is visible on the outside of the water pump, this does not usually indicate damage. Instead, it is a result of the water pumps being equipped with a special gasket system on the rotating shaft. The cooling system is sealed on the shaft with a sliding ring seal. This gasket consists of a fixed part and a rotating part. A spring compresses the two parts, to keep the cooling system sealed even when in an unpressurised state. Both of the sliding ring’s contact surfaces are lubricated and cooled together using the cooling liquid. This type of construction automatically causes small quantities of coolant agent to repeatedly leak through the contact surfaces. As a result, a small amount of cooling liquid or coloured deposits may become visible on the leakage hole or outer face of the water pump. This can lead to confusion, in particular after installation during the leak test. However, a certain amount of leakage is normal, and not a cause for concern.

Replacing the coolant agent

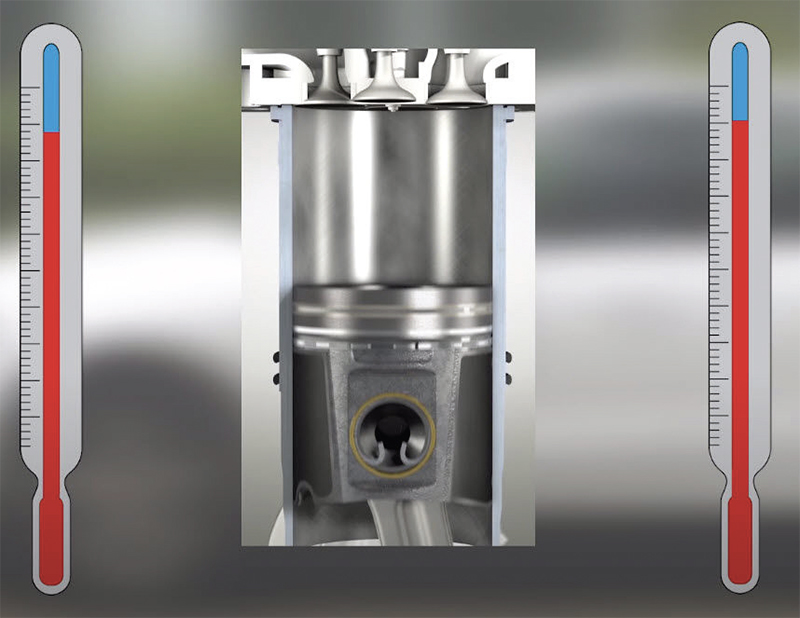

However, if larger quantities of the coolant agent leak through the sliding ring seal over longer periods of time, and therefore also escape via the leakage hole, this is usually caused by impurities in the coolant agent. This is because if the cooling system is not cleaned when the pump is changed, or if contaminated coolant agent is used, lime, rust and dirt can cause increased wear of the contact surfaces, leading to coolant leakage. To prevent this, it is absolutely necessary to make sure that the specified change intervals of the coolant agent are adhered to.

After performing any work on the cooling system

The cooling system must always be vented according to the manufacturer’s instructions.

State-of-the-art vehicles have one or more coolant circuits, which divide into different branches, and are closed or released depending on the operating state. In many cases, either several electrical water pumps are installed, or a combination of electrical and switchable mechanical water pumps.

If the system is not vented according to the specifications of the vehicle manufacturer, air can build up in all of these branches and components. This can lead to malfunctions, and in some cases, damage to the components or engine. When this happens, the risk is not only that the water pumps could run dry. Air bubbles in the system can also impair heat transfer. This can cause heat to build up in some areas (hotspots), which could, for example, directly damage the circuit board of an electrical coolant pump, or cause the electronic components to age prematurely.